+86-13516964051

+86-13516964051 Understanding Sand Casting Disadvantages for ODM Manufacturers and Suppliers

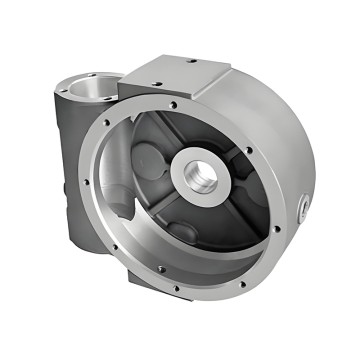

When evaluating the challenges of Sand Casting Disadvantages, it's crucial to consider the implications for your production process. As an experienced buyer, I recognize that while sand casting is versatile, it can present issues like surface finish limitations and dimensional inaccuracies. Collaborating with a reputable manufacturer such as Yongkang Hantai Industry And Trade Co., Ltd. can significantly improve outcomes. Our skilled team is well aware of these challenges and is committed to providing precision and durability in our sand cast products. We are dedicated to guiding you through the process, ensuring that your specific requirements are met. With our expertise, you can navigate the disadvantages of sand casting while enjoying a strong, dependable partnership that enhances your production capabilities. Choose us for an efficient experience and outstanding results that align with your operational objectives!

Avoiding Pitfalls Sand Casting Disadvantages Products Manufacturers You Can Rely On

When it comes to selecting manufacturing partners for sand casting products, avoiding pitfalls is crucial for global buyers. Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, has positioned itself as a reliable provider within the automotive industry. We understand that while sand casting is a widely used method for producing intricate shapes, it comes with its own set of challenges and disadvantages that procurement professionals must navigate. One common pitfall is the inconsistency in quality that can arise from varied sand Casting Techniques. At Yongkang Hantai, we prioritize technological innovation and strict quality control processes, ensuring that our parts meet high standards and specifications. Our commitment to quality improvement drives our continuous investments in newer technologies, which helps mitigate issues such as dimensional inaccuracies or defects in the final products. By partnering with us, global buyers can rely on a steady supply of high-quality components tailored to their needs. Another disadvantage of sand casting is the longer lead times that can result from the setup and curing processes. However, our years of experience enable us to optimize production schedules while maintaining the quality of our offerings. By choosing Yongkang Hantai as your manufacturing partner, you gain access to a dedicated team that understands the importance of timely delivery and can effectively address any challenges that may arise in the production process. Trust us to provide the reliable parts and components your business needs to thrive in the competitive automotive market.

Avoiding Pitfalls Sand Casting Disadvantages Products Manufacturers You Can Rely On

| Manufacturer Type | Location | Years in Business | Common Products | Sand Casting Disadvantages |

|---|---|---|---|---|

| Metal Foundry | USA | 15 | Automotive Parts | High surface roughness |

| Precision Casting Shop | Germany | 20 | Marine Components | Limited dimensional accuracy |

| Industrial Foundry | China | 10 | Heavy Machinery Parts | Long lead times |

| Custom Foundry | India | 8 | Architectural Components | Porosity in castings |

| Artisan Foundry | Canada | 5 | Decorative Items | Inconsistent quality |

Effective Ways To Sand Casting Disadvantages Pioneers in the Field Outperforms the Competition

L

Lucas Wilson

Great quality product! The customer service team was very professional, providing all the information I needed. Highly recommend!

29 June 2025

A

Aria Cooper

What a fantastic purchase! The quality is unmatched, and the after-sale service was exemplary with professional support.

16 May 2025

L

Layla Lee

Incredible product quality! The support showed great professionalism, ensuring all my questions were answered.

23 June 2025

S

Stella Rodriguez

Absolutely love this product! Support staff were quick and professional, addressing all my concerns impressively.

30 June 2025

E

Elias Young

Incredible quality craftsmanship! The customer service team was knowledgeable and made the process a breeze.

25 June 2025

B

Bella Lee

Wonderful product quality from top to bottom! The customer service was professional and attentive to my needs.

18 May 2025