+86-13516964051

+86-13516964051 Why Can Aluminum Alloy Die Casting Form Complex Parts?

Why Can Aluminum Alloy Die Casting Form Complex Parts?

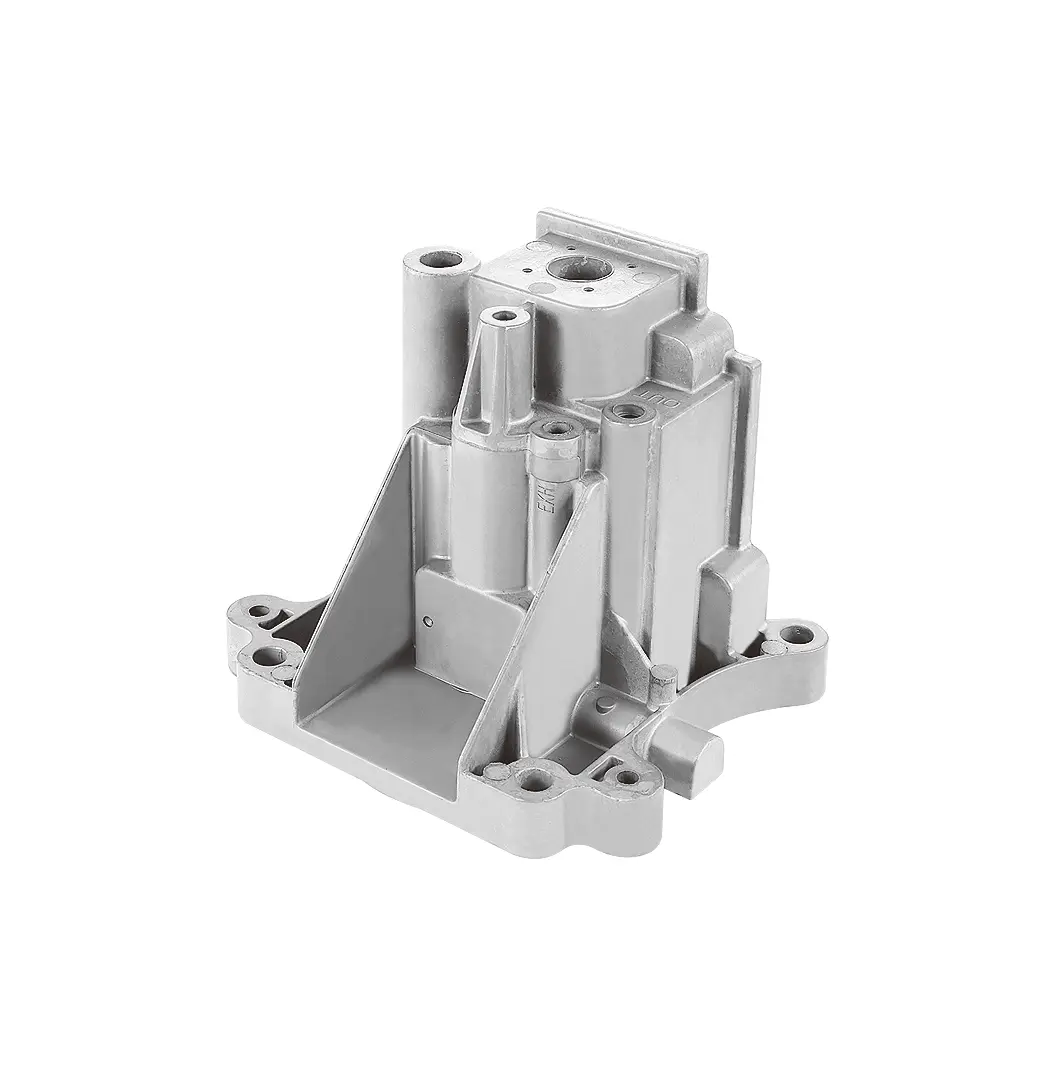

In the field of precision manufacturing, aluminum alloy die casting, with its exceptional ability to mold complex structures, has become a core process of choice in industries such as automotive, electronics, and aerospace. From tiny heat sinks in smartphones to integrated battery housings for new energy vehicles, how can aluminum alloy die casting accurately form parts filled with irregular holes, complex ribs, and curved surfaces? The answer lies in the synergy of material properties, process principles, and equipment technology.

I. Material DNA: The "Innate Adaptability" of Aluminum Alloys

The molding of complex parts relies primarily on the material's inherent plasticity and fluidity, and aluminum alloys perfectly meet these two core requirements.

Although its density is only one-third that of iron, its strength can be enhanced by adding alloying elements such as silicon, magnesium, and copper. For example, the commonly used ADC12 aluminum alloy boasts a tensile strength exceeding 220 MPa, meeting the mechanical requirements of most structural parts. Crucially, aluminum alloy possesses excellent fluidity in its molten state. At temperatures of 650-720°C, the viscosity of molten aluminum is only one-fifth that of molten steel. It can penetrate the fine lines of a mold like water, completely filling even narrow gaps as narrow as 0.5mm and micro-vias as small as 1mm in diameter.

Furthermore, aluminum alloy's solidification shrinkage is as low as 1.0%-1.2%, and the shrinkage process is relatively uniform. This means that parts are less likely to crack or deform due to stress concentration after cooling. For parts with complex internal cavities and multi-directional ribs, this stable volume change is essential for ensuring dimensional accuracy.

II. Core Process: The "Dual Guarantee" of High-Pressure Injection and Precision Molds

If aluminum alloy is the "forming material," then the high-pressure die-Casting Process and precision molds are the "magic hands" that create complex shapes. (I) High Pressure and High Speed: Overcoming the Difficulty of Filling Complex Structures

The core advantage of the die-casting process lies in "high-pressure injection"—molten aluminum is injected into the mold cavity at a speed of 5-50 m/s under high pressure (10-150 MPa). This extreme filling method allows the molten aluminum to rapidly fill any complex spatial structure before solidification (in just 0.1-2 seconds). Whether it's the irregularly shaped gear cavity in an automotive transmission or the dense microchannels of a 5G base station heat sink, high pressure overcomes the resistance of the molten aluminum during flow, ensuring that every tiny corner is completely filled.

More importantly, high pressure allows the molten aluminum to adhere tightly to the mold surface, not only replicating the mold's precise textures (surface roughness can reach Ra 0.8-1.6μm), but also offsetting volume shrinkage during solidification through "pressure feeding," preventing defects such as shrinkage cavities and porosity. This is crucial for achieving the airtightness and strength requirements of complex parts. (II) Precision Molds: "Replica Blueprints" for Complex Shapes

The mold directly determines part shape. Precision machining technology for aluminum alloy die-Casting Molds makes it possible to form complex structures. Modern die-casting molds utilize H13 hot-work die steel. Through multiple precision processes, including CNC milling, electrical discharge machining (EDM), and wire cutting (WEDM), they can produce cavity structures with tolerances within ±0.02mm.

For parts with complex features such as undercuts and side holes, the mold is equipped with a "core pulling mechanism." This mechanism uses hydraulically or mechanically driven slides to precisely extract the lateral core after the molten aluminum solidifies, enabling the integrated molding of special-shaped structures that are impossible with traditional casting. For example, the motor end caps of new energy vehicles often integrate multiple complex features, such as flanges, bearing seats, and wiring holes. Through the coordinated action of three to five sets of core pulling mechanisms, the die-casting mold can complete the entire structure in a single pass, eliminating the need for subsequent welding or cutting. In addition, precise cooling channels are designed within the mold to perfectly match the complex shape of the part. This ensures uniform cooling of the molten aluminum across different areas, further reducing deformation caused by uneven temperatures and ensuring the dimensional stability of complex parts.

III. Technological Upgrades: The "Power of Advancement" Driving Complex Forming

With the evolving demands of manufacturing, aluminum alloy die-casting technology continues to advance, making "more complex, higher-precision" forming a reality.

(I) Integrated Die Casting: Conquering Large, Complex Structures

Traditional die casting is limited by the clamping force of the equipment, making it difficult to form large, complex parts. Integrated die casting technology, however, utilizes ultra-large die-casting machines (with clamping forces of 6,000-12,000 tons) to achieve a breakthrough in forming by integrating multiple parts. For example, the rear floor of a new energy vehicle, which originally required welding of over 70 stamped parts, can be completed with a single set of molds and a single molding process. This not only reduces the risk of welding defects but also reduces part weight by 15%-20%, increasing production efficiency by over 80%. This technology can easily handle large parts exceeding 2 meters in length with complex reinforcement ribs and mounting interfaces, breaking the size limitations of traditional processes.

(II) Vacuum Die Casting: Improving the Internal Quality of Complex Parts

For complex parts requiring high airtightness and fatigue strength, such as engine blocks and hydraulic valve bodies, vacuum die casting technology is key. This technology evacuates the mold cavity (to a vacuum level of less than 50 mbar) to expel air and gases from the cavity, preventing the formation of porosity during aluminum filling. Data shows that vacuum die casting can reduce part porosity to below 0.5%, improving airtightness by 3-5 times, allowing complex parts to operate stably even in high-pressure and high-temperature environments.

(III) Numerical Simulation: Anticipating Potential Risks in Complex Forming

Before production, die-casting numerical simulation software (such as ProCAST and MAGMA) can be used to perform 3D simulations of the aluminum filling and solidification processes. Engineers can clearly visualize the flow of molten aluminum within complex mold cavities, predicting potential problems such as underfill, air entrapment, and thermal cracking, and proactively optimize mold structure and process parameters (such as gate location, injection speed, and cooling method). This "virtual mold trial" technology not only reduces the development cost of complex parts but also shortens the mold trial cycle from 3-6 months to 1-2 months, accelerating product launch.

IV. Application Verification: "Industry Practice" of Complex Forming

The complex forming capabilities of aluminum alloy die-casting have been fully demonstrated in multiple high-end fields:

In the automotive industry, the rear floor of the Tesla Model Y utilizes a 6,000-ton integrated die-cast process, integrating the functions of 37 components. The component features over 200 mounting holes and complex reinforcement ribs, with dimensional tolerances within ±0.5mm.

In the electronics industry, the aluminum alloy unibody of the Apple MacBook achieves seamless integration of curved and flat surfaces through precision die-casting. With a thickness of only 3mm, it integrates numerous microstructures, such as heat sinks and interface grooves, achieving mirror-like surface finish.

In the aerospace sector, the aluminum alloy landing gear bracket of a certain drone model is formed using vacuum die-casting technology. The part features a special-shaped load-bearing cavity and multi-directional connection tabs, and boasts a tensile strength of 300MPa, capable of withstanding impact loads under extreme operating conditions.

V. Comparative Advantages: Why is aluminum alloy die-casting the preferred choice for complex parts?

Compared to other molding processes, aluminum alloy die-casting offers irreplaceable advantages in complex part manufacturing:

Process Type

Complex Structure Forming Capability

Dimensional Accuracy

Production Efficiency

Cost Control

Aluminum Alloy Die-Casting

★★★★★

±0.02-0.1mm

Tens to hundreds of pieces per hour

Medium to low (integrated molding reduces subsequent processing)

Sand Casting

★★★☆☆

±1-3mm

Several pieces per hour

Low (but high defect rate)

3D Printing (Metal)

★★★★☆

±0.05-0.1mm

Several hours/piece

Extremely high (unsuitable for mass production)

Machining

★★☆☆☆

±0.01mm

Long cycle time per piece

High (low material utilization)

Clearly, aluminum alloy die-casting achieves the perfect balance of complex structures, high precision, high volume, and low cost, which is why it has become the preferred process for complex part manufacturing.

Conclusion: The "Manufacturing Logic" Behind Complex Forming

The ability of aluminum alloy die-casting to handle complex-shaped parts stems from the deep synergy of "material properties × process principles × equipment technology": the fluidity and stability of aluminum alloys are fundamental, high-pressure, high-speed filling methods are the core, and precision molds and technological advancements are the guarantee. From microscopic miniature parts to macroscopic integrated structures, aluminum alloy die-casting is constantly pushing the boundaries of "complex forming."