+86-13516964051

+86-13516964051 The Core Role of Hydraulic Automation in Aluminum Alloy High-Pressure Casting

The Core Role of Hydraulic Automation in Aluminum Alloy High-Pressure Casting: Efficiency, Precision, and the Driving Force for Industrial Upgrading

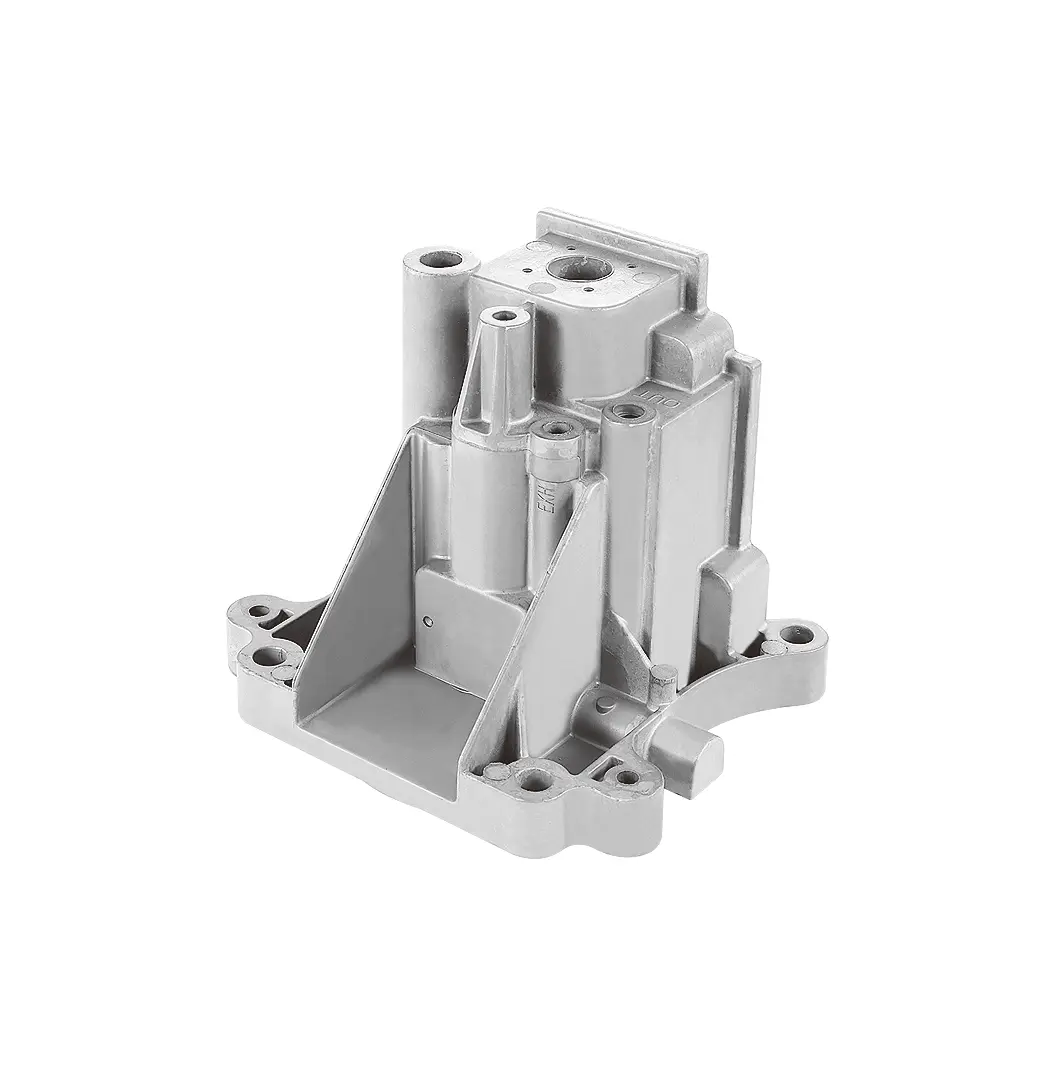

Amid the manufacturing industry's shift toward intelligent and efficient manufacturing, aluminum alloy high-pressure casting, with its ability to rapidly produce complex, high-strength castings, has become a core process in high-end sectors such as automotive, aerospace, and electronics. Breakthroughs and upgrades in this process have always relied on the technical support of hydraulic automation equipment. From pressure control during casting to automated production processes, hydraulic automation equipment is not only the driving force behind high-pressure casting but also a key factor in determining product quality, production efficiency, and corporate competitiveness. This article will deeply analyze the core role of hydraulic automation equipment in aluminum alloy high-pressure casting, revealing how it is driving the foundry industry's transition from "traditional manufacturing" to "precision intelligent manufacturing."

I. Process Characteristics of Aluminum Alloy High-Pressure Casting: Why Hydraulic Automation Equipment is the "Best Partner"

To understand the value of hydraulic automation equipment, we must first understand the fundamental nature of aluminum alloy high-pressure casting—a Casting Method in which molten aluminum alloy is pressed into a metal mold cavity at high pressure and speed, where it rapidly solidifies under pressure. The core requirements can be summarized as "three highs": high pressure stability (to ensure the density of the casting), high motion precision (to match complex mold opening and closing and core pulling movements), and high response speed (to accommodate short-cycle mass production).

Traditional mechanical transmission or pneumatic equipment often have significant limitations when meeting these requirements: Mechanical transmission structures are bulky, making it difficult to achieve flexible adjustment of complex movements; pneumatic systems are affected by the compressibility of gas, resulting in large pressure fluctuations and unable to meet the needs of high-precision molding. Hydraulic automation equipment, with its inherent advantages of hydraulic transmission, perfectly addresses the pain points of high-pressure casting:

High force density: Within the same volume, the hydraulic system can output greater driving force, easily meeting the 10-150 MPa filling pressure requirements of high-pressure casting.

High control precision: Through components such as proportional valves and servo valves, pressure and flow can be continuously and steplessly adjusted, with pressure fluctuations controlled within ±0.5%.

Fast response speed: The incompressibility of hydraulic oil ensures rapid start/stop and switching of actuators (such as the shot cylinder and clamping cylinder), reducing response time to less than 0.1 second.

Strong adaptability: A single hydraulic system can drive multiple actuators to work in concert, easily adapting to the molding needs of castings of varying specifications and reducing equipment replacement costs.

The technical characteristics of hydraulic automation equipment are a natural fit with the process requirements of aluminum alloy high-pressure casting, laying the foundation for large-scale, high-precision production of high-pressure casting.

II. Key Applications of Hydraulic Automation Equipment in the Entire High-Pressure Casting Process

Aluminum alloy high-pressure casting is a continuous process encompassing "mold closing - injection - pressure holding - mold opening - part removal." Hydraulic automation equipment is integrated throughout each critical step, ensuring casting quality and production stability through precise power control and coordinated motion.

1. Mold Closing and Locking: The "Basic Guarantee" of Casting Form

Mold closing and locking are the first steps in high-pressure casting and directly determine the tightness and stability of the mold closure. If the clamping force is insufficient, the molten aluminum alloy can easily expand the mold parting surface during high-pressure filling, resulting in flash, burrs, and even casting rejection. If the clamping force is too high, mold wear and equipment energy consumption will increase. Hydraulic automation equipment combines a double-acting clamping cylinder with a force-amplifying mechanism (such as a toggle or direct pressure type) to precisely control clamping force:

During the clamping phase, the hydraulic system drives the clamping cylinder to smoothly push the movable mold at a low speed to prevent mold collisions. Once the mold is closed, the system switches to "high-pressure clamping" mode based on feedback from a pressure sensor.

During the clamping phase, a proportional pressure valve regulates system pressure to precisely match the clamping force to the projected area of the casting and the filling pressure (typically, the clamping force is 1.2-1.5 times the filling pressure). For example, when producing automotive transmission housings, the clamping force can be flexibly adjusted to 500-20,000 kN depending on the casting size.

During the holding phase, after clamping, the hydraulic system maintains a stable pressure to prevent mold displacement during filling and ensure dimensional accuracy.

Furthermore, for complex molds (such as those with side core pulls or inclined ejector mechanisms), hydraulic automation equipment can synchronize the core pulling action with the clamping and opening phases, preventing mold jams and component damage.

2. Injection Molding: The Core Step Determining Casting Density

Injection molding is the key step in high-pressure Aluminum Alloy Casting. Molten aluminum alloy must fill the mold cavity under high pressure and high speed. The injection speed and pressure curve directly affect the density, porosity, and mechanical properties of the casting. Hydraulic automation equipment plays a dual role in this process, serving as both a "power engine" and a "precision controller." The servo-hydraulic injection system enables multi-stage, refined control:

Slow-speed injection phase: The hydraulic system drives the injection cylinder to advance the injection punch at a low speed, smoothly pushing the molten aluminum alloy into the injection chamber to prevent splashing or air entrainment. The speed is typically controlled at 0.1-0.5 m/s.

Fast-speed injection phase: After the punch passes the gate, the hydraulic system rapidly increases the injection speed via a flow valve, allowing the molten metal to fill the mold cavity quickly (typically 0.02-0.05 seconds). Speeds can reach as high as 3-8 m/s to prevent premature solidification during the filling process.

Pressure-holding phase: After mold filling is complete, the hydraulic system instantly switches to high-pressure holding mode, using the booster cylinder to increase the pressure to 10-150 MPa. This compacts the molten metal in the mold cavity, reduces defects such as porosity and shrinkage, and maintains the casting's dimensional stability. Compared to traditional fixed-displacement hydraulic systems, the servo variable pump hydraulic system widely used in modern high-pressure casting can further optimize injection performance. A servo motor drives the variable pump, adjusting flow and pressure in real time based on injection requirements. This not only enhances shot curve control (pressure fluctuation can be controlled to ±0.3%), but also reduces energy consumption by 30%-40%, aligning with the development trend of green manufacturing.

3. Mold Opening and Part Removal: The "Automated Link" for Improving Production Efficiency

Large-scale production in high-pressure casting relies on process continuity. The efficiency of mold opening and part removal directly determines the production line cycle time. Hydraulic automation equipment, in conjunction with robotic arms, conveyor belts, and other automated devices, enables unmanned operation in this process:

Mold opening: After the casting solidifies, the hydraulic system drives the mold clamping cylinder in reverse, allowing the movable mold to open smoothly. The mold opening speed can be flexibly adjusted based on the degree of adhesion between the casting and the mold to prevent deformation or dislodging of the casting.

Part removal and auxiliary operations: After mold opening, the hydraulic system controls the lifting, retraction, and rotation of the part removal robot to precisely grasp the casting. Simultaneously, a hydraulically driven ejector cylinder ejects the casting from the mold. The ejection force and speed can be adjusted in real time using a proportional valve to prevent damage.

Process integration: The hydraulic system is linked to the production line's PLC control system to achieve a fully automated cycle of "mold opening - part removal - mold cleaning - painting - mold closing," reducing production cycle times to 30-60 seconds per part, significantly reducing the 2-3 minutes per part achieved with traditional manual operations.

III. The Core Value of Hydraulic Automation Equipment for the High-Pressure Casting Industry

The widespread use of hydraulic automation equipment not only optimizes the production process for aluminum alloy high-pressure casting but also creates significant value for businesses in terms of quality, efficiency, cost, and safety, driving the upgrading and iteration of the entire industry.

1. Improving Casting Quality: From "Qualified" to "Excellent"

Casting quality is the core competitive advantage of high-pressure casting. Hydraulic automation equipment fundamentally improves both the intrinsic quality and the appearance of castings through precise pressure and speed control:

Reducing Defects: Stable clamping force and injection pressure curves effectively reduce defects such as flash, burrs, air holes, and shrinkage, increasing the casting qualification rate from 70%-80% with traditional processes to over 95%;

Optimizing Performance: Precise control during the high-pressure holding phase increases casting density, boosting the tensile strength of aluminum alloy castings by 10%-15% and the elongation by 8%-12%, meeting the mechanical requirements of high-end applications such as automotive chassis and aviation components;

Guaranteed Precision: The hydraulic system drives mold movement with an accuracy of up to 0.01mm, ensuring that casting dimensional tolerances are within IT8-IT10, reducing subsequent machining and lowering processing costs. Taking the automotive industry as an example, aluminum alloy wheels produced using a servo-hydraulic injection molding system not only reduce porosity to below 0.5%, but also reduce fuel consumption through lightweight design, meeting the development needs of new energy vehicles.

2. Improving Production Efficiency: Achieving Both Scale and Flexibility

Against the backdrop of cost reduction and efficiency improvement in the manufacturing industry, hydraulic automation equipment significantly improves high-pressure casting production efficiency through automated collaboration and rapid response capabilities:

Shortening Production Cycle Time: The fully automatic hydraulic control system reduces the production cycle of a single die-casting machine from the traditional 2-3 minutes per part to 30-60 seconds per part, increasing single-shift output by 2-3 times;

Enabling Multi-Variety Production: Through the coordinated control of the PLC and hydraulic systems, a single set of equipment can rapidly switch molds and process parameters to meet the production needs of castings of varying specifications, reducing mold change time from the traditional 1-2 hours to 15-30 minutes;

Reducing Manual Intervention: The hydraulically driven automated removal, cleaning, and spraying systems can replace over 80% of manual operations, reducing labor costs and eliminating quality fluctuations caused by manual intervention. After a large automotive parts manufacturer introduced a servo-hydraulic die-casting production line, its daily production of aluminum alloy transmission housings increased from 800 to 2,000 units. Labor costs were also reduced by 60%, and the payback period was shortened to 1.5 years.

3. Reduced Overall Costs: Comprehensive Optimization from "Energy Consumption" to "Maintenance"

Hydraulic automation equipment not only improves quality and efficiency, but also achieves a closed-loop "cost reduction and efficiency improvement" through technological innovation:

Reduced Energy Consumption: Traditional fixed-displacement pump hydraulic systems waste energy by "a large horse pulling a small cart." Servo variable pump hydraulic systems adjust output power in real time based on load demand, reducing energy consumption by 30%-40%, saving a single die-casting machine 100,000-200,000 yuan in electricity bills annually.

Reduced Mold Wear: Smooth mold closing and opening movements and precise clamping force control reduce mold impact wear, extending mold life from the traditional 50,000-80,000 cycles to 100,000-150,000 cycles, reducing mold replacement costs by over 50%.

Simplified Maintenance: Modern hydraulic systems are equipped with online monitoring devices for pressure, temperature, and oil contamination, providing real-time warnings of potential failures and avoiding unplanned downtime. Furthermore, the modular design of hydraulic components facilitates maintenance and replacement, reducing downtime to 2-4 hours. times.

4. Ensuring Production Safety: From "Passive Protection" to "Active Warning"

High-pressure casting involves high-temperature molten metal and high-pressure equipment, posing a high safety risk. Hydraulic automation equipment utilizes multiple safety features to create a comprehensive protection system:

Mechanical Protection: A hydraulically driven safety gate is linked to the equipment's operation. If the gate is not closed, the system automatically shuts off mold clamping and injection, preventing personnel from entering hazardous areas.

Pressure Protection: The system is equipped with an overload relief valve and pressure sensor. When the clamping force or injection pressure exceeds the set value, it automatically releases pressure and shuts down the machine, preventing equipment damage or mold explosion.

Intelligent Warning: Leveraging IoT technology, the hydraulic system transmits real-time data such as pressure, temperature, and oil status to a cloud platform, enabling remote monitoring and fault warnings, helping to proactively mitigate safety hazards.

IV. Future Trend: The "Intelligent Integration" of Hydraulic Automation Equipment and High-Pressure Casting

With the advancement of Industry 4.0 and intelligent manufacturing, the role of hydraulic automation equipment in aluminum alloy high-pressure casting will be further enhanced, demonstrating a development trend of "intelligence, integration, and greenness."

1. Intelligent Control: From "Precision" to "Prediction"

Future hydraulic systems will integrate the Industrial Internet, big data, and AI algorithms, transforming from "passive control" to "active prediction":

Sensors installed on hydraulic components (such as pressure sensors, displacement sensors, and vibration sensors) collect real-time data such as injection force, mold closing speed, and oil temperature. A "digital twin" model is constructed to simulate casting quality under different process parameters and automatically optimize process parameters.

AI algorithms analyze historical data to predict the lifespan of hydraulic components (such as seal and hydraulic pump wear), allowing maintenance to be scheduled in advance and avoiding unplanned downtime.

Coordinated control of the hydraulic systems of multiple die-casting machines is achieved, automatically allocating production tasks based on order demand and optimizing production scheduling efficiency.

2. Integrated Design: From "Single Function" to "System Solution"

Hydraulic automation equipment will be deeply integrated with robotics, visual inspection, and the MES system to form an "integrated intelligent casting solution":

The hydraulic system will work in conjunction with the visual inspection equipment to automatically inspect casting dimensions and appearance defects after removal. Any defects detected will be immediately fed back to the hydraulic system, automatically adjusting parameters such as injection pressure and hold time, achieving "closed-loop quality control."

The hydraulic system will be connected to the MES system to upload production data (such as output, energy consumption, and defect rate) to the management platform in real time, enabling full traceability and digital management of the production process.

The development of a "modular hydraulic unit" will allow for rapid assembly based on the specifications of different die-casting machines, shortening equipment development and commissioning cycles.

3. Green Upgrade: From "Energy Saving" to "Zero Emissions"

Driven by the "dual carbon" goals, hydraulic automation equipment will develop towards "low energy consumption and low pollution":

Promoting electric hydraulic systems (electro-hydraulic servo systems) to replace traditional hydraulic pumps will further reduce energy consumption and noise pollution (noise levels can be reduced from 85dB to below 70dB);

Developing biodegradable hydraulic fluids to replace mineral hydraulic fluids and reduce environmental pollution from oil leaks;

Implementing "circulating filtration" and "online purification" of hydraulic oil to extend oil life and reduce waste oil emissions.

Conclusion: Hydraulic Automation Equipment - The Core Engine for the Upgrading of the High-Pressure Casting Industry

The development of aluminum alloy high-pressure casting is essentially a story of "process requirements driving equipment innovation." From traditional manual hydraulic systems to modern servo-hydraulic systems, and then to future intelligent hydraulic systems, hydraulic automation equipment has always been the core driving force behind breakthroughs in high-pressure casting technology. It not only solves the core pain points of "pressure, precision, and efficiency" in high-pressure casting, but also promotes the transformation of the casting industry from "labor-intensive" to "technology-intensive" through integration with intelligent manufacturing technology.