+86-13516964051

+86-13516964051 Strategies for Improving Die-Casting Quality: Optimizing Low-Shot Speed

Strategies for Improving Die-Casting Quality: Optimizing Low-Shot Speed

In aluminum alloy high-pressure die-casting production, optimizing low-shot speed plays a crucial role in improving die-casting quality. This article will delve into strategies for optimizing low-shot speed and its impact on die-casting quality, aiming to provide a comprehensive and professional reference for high-end wholesale buyers worldwide.

I. The Importance of Low-Shot Speed

In the aluminum alloy high-pressure die-Casting Process, the speed parameters during the low-shot speed phase have a significant impact on casting quality. Excessively high shot speeds can cause a large amount of air to enter the mold cavity through the pressure chamber and cause turbulence in the molten aluminum within the pressure chamber, increasing the gas content in the molten aluminum and thus affecting the quality of the die-casting. Excessively low shot speeds can result in cold shuts and poor forming. Therefore, optimizing low-shot speed is a key factor in ensuring die-casting quality.

II. Strategies for Optimizing Low-Shot Speed

(I) Optimization Using Virtual Testing Software

Virtual testing software (such as Magma) plays an important role in optimizing low-shot speed. By simulating the filling and molding process, the software automatically generates multiple simulation scenarios based on set optimization objectives (such as reducing air pressure, reducing air entrapment, and improving filling smoothness). The software then analyzes and compares the simulation results to select the solution that meets the optimization objectives. For example, in the die-casting process for an automotive oil cooler, Magma software was used to simulate multiple parameter sets during the low-speed injection phase. Based on the simulation results, the optimal low-speed die-casting process parameters were selected. Die-casting trials verified that the optimal low-speed parameters produced high-quality castings, ensuring process stability, shortening the Casting Development cycle, and improving economic efficiency.

(II) Setting a Reasonable Low-Speed Range

The specific requirement for low-speed is to smoothly push the molten metal at a constant speed or uniform acceleration within the low-speed range (0.1-0.5 m/s). This speed range prevents turbulence in the molten metal that can lead to the incorporation of gases, thereby reducing the gas content in the molten metal and facilitating the smooth discharge of gases within the mold cavity. In practice, the appropriate low-speed value should be selected based on the specific casting structure and process requirements. For example, in the die-casting process for the transmission main housing, simulation analysis revealed that a low-speed injection velocity of 0.2 m/s resulted in the smoothest filling process and the lowest probability of air entrapment.

(III) Optimizing the High-Low Speed Switching Point

The setting of the high-low speed switching point also significantly impacts the quality of die-Cast Parts. If the switching point is set too early, the molten metal will spray under the high-speed injection, resulting in large amounts of splashing and increasing the probability of porosity defects. Appropriately delaying the high-low speed switching point allows the molten metal to flow smoothly into the mold cavity and disperse evenly, thereby improving the jet flow during the filling process. For example, in the die-casting process for the transmission main housing, a high-low speed switching point of 560 mm resulted in the smoothest filling process and the lowest probability of air entrapment.

(IV) Verification and Adjustment in Real-World Production

The optimal low-speed parameters identified through virtual testing still need to be verified and adjusted in real-world production. In real-world production, various external factors, such as temperature, humidity, and equipment conditions, may affect the quality of die-cast parts. Therefore, it is necessary to closely monitor casting quality during actual production and fine-tune low-speed parameters based on actual conditions to ensure stable and consistent casting quality.

III. The Impact of Optimizing Low-Speed Injection on Die-Casting Quality

(I) Improving Internal Casting Quality

Optimizing low-speed injection can significantly improve the internal quality of castings. By reducing the generation of porosity and air entrapment, the density and strength of the casting can be increased. For example, in the die-casting process of a certain automotive oil cooler, castings produced using optimized low-speed parameters showed a significant reduction in internal porosity, with the porosity level meeting the requirements of ASTM E505 aluminum alloy porosity (shrinkage) porosity Grade 2. This not only improves the mechanical properties of the casting but also reduces the risk of leakage during use.

(II) Improving Casting Surface Quality

Optimizing low-speed injection can also improve the surface quality of the casting. By reducing turbulence and jetting of the molten metal during mold filling, defects such as cold shuts and flow marks can be avoided on the casting surface. For example, in the die-casting process for the transmission main housing, castings produced using optimized high- and low-speed switching points exhibit smooth surfaces and no noticeable defects. This not only improves the casting's appearance but also reduces the difficulty and cost of subsequent processing.

(III) Improving Production Efficiency and Economic Benefits

Optimizing the low-speed injection process not only improves casting quality but also enhances production efficiency and economic benefits. By reducing scrap rates and shortening development cycles, production costs can be reduced. For example, in the die-casting process for a certain automotive oil cooler, the total scrap rate for castings produced using optimized low-speed parameters was only 3%. This not only improved production efficiency but also enhanced the company's economic benefits.

IV. Actual Case Analysis

(I) Die-casting Process Optimization for a Certain Automotive Oil Cooler

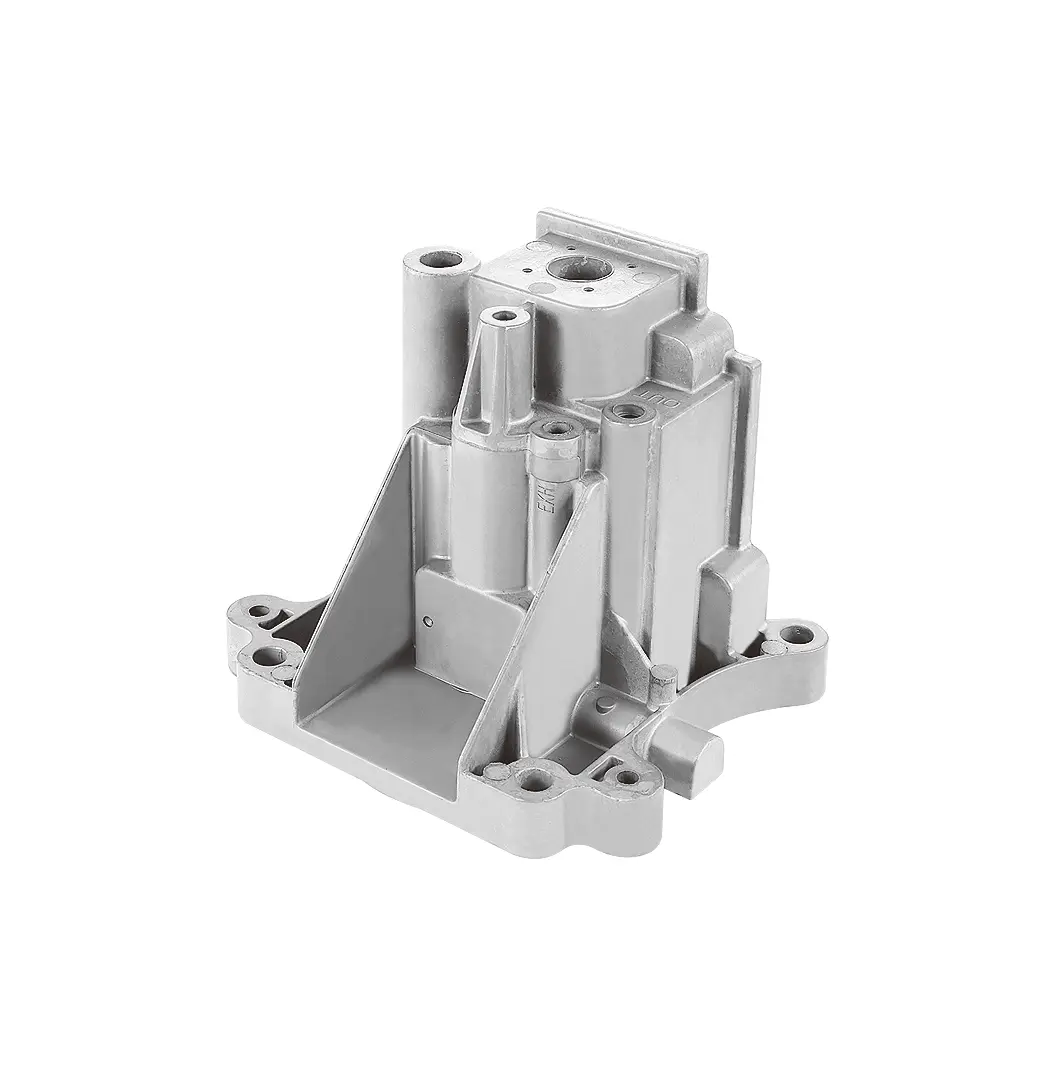

The blank mass of the casting for a certain automotive oil cooler was 0.463 kg, and the mass of the gating and overflow system was 0.252 kg. The material was AlSi9Cu3. The basic dimensions of the casting were 155 mm × 136 mm × 45 mm, with an average wall thickness of 5 mm, with a maximum wall thickness of 15 mm and a minimum wall thickness of 3 mm. The casting structure is complex, with precast oil passage hole A being 81 mm long and precast oil passage hole B being 62 mm long. The casting surface must be free of cold shuts, bubbles, or peeling. Internal porosity must meet ASTM E 505 aluminum alloy gas (shrinkage) porosity Grade 2. Leak testing requires a leakage value of no more than 5 mL/min at 620 ± 10 kPa.

In the process of optimizing the low-speed injection process, Magma software was first used to simulate multiple parameters during the low-speed injection phase. Based on the simulation results, the optimal low-speed die-casting process parameters were selected. Die-casting trials verified that the optimized low-speed parameters produced excellent casting quality, with a total scrap rate of 3%. This demonstrates that optimizing the low-speed injection process can significantly improve casting quality and reduce scrap rates.

(II) Die-casting Process Optimization of the Transmission Main Housing

The transmission main housing is a key component of automotive transmissions, and its quality is directly related to vehicle performance and safety. Through simulation analysis and actual production verification, the low-speed injection process and the high-low speed switching point were optimized for the transmission main housing die-casting process. When the low injection speed is 0.2 m/s, the high injection speed is 3.5 m/s, and the high-low speed switching point is 560 mm, the casting filling process is the most stable, and the probability of air entrapment is minimized. Using these process parameters in actual production, the castings have dense microstructures and good mechanical properties.

V. Conclusion

Optimizing the low injection speed is an effective strategy for improving the quality of aluminum alloy high-pressure Die Castings. By optimizing using virtual testing software, setting a reasonable low speed range, optimizing the high-low speed switching point, and combining actual production verification and adjustment, the internal quality and surface quality of the castings and production efficiency can be significantly improved.