+86-13516964051

+86-13516964051 Specific application of aluminum alloy castings in spacecraft

Specific application of Aluminum Alloy Castings in spacecraft

With the rapid development of aerospace technology, aluminum alloy castings are increasingly used in spacecraft manufacturing. Aluminum alloys have become an indispensable material in spacecraft manufacturing due to their unique physical and mechanical properties. This article will discuss in detail the specific application of aluminum alloy castings in spacecraft, as well as the advantages and future development directions they bring.

1. Advantages of aluminum alloy castings in spacecraft

(I) Lightweight and high strength

Aluminum alloy is a lightweight and high-strength metal material. Its specific gravity is only about one-third of that of steel, but its specific strength is about 35% higher than that of ordinary carbon steel. It has excellent mechanical properties such as tensile strength and yield strength. The use of aluminum alloys can greatly reduce the overall weight of spacecraft and improve load capacity and flight performance. For example, 44% of the weight of the fuselage of Airbus's A380 passenger aircraft is composed of aluminum alloys.

(II) Excellent corrosion resistance

Aluminum alloys have good corrosion resistance and good tolerance to most acids and alkalis. This is very important for spacecraft that operate in the air for a long time. Aluminum alloy parts can be used to manufacture the outer shell of aircraft, as well as the brackets and shells of various aviation instruments.

(III) High thermal conductivity

The thermal conductivity of aluminum alloy is very good, which makes it possible to manufacture some parts that require high heat transfer efficiency, such as heat sinks, coolers and heat transfer pipes in aircraft engines.

(IV) Ease of processing and formability

Aluminum alloy has good plasticity and good machinability, which makes it easy to be manufactured into parts of various shapes and sizes. In addition, aluminum alloy can be processed by a variety of processing methods, such as extrusion, stretching, cold drawing, welding, casting and other methods.

2. Specific application of aluminum alloy castings in spacecraft

(I) Engine parts

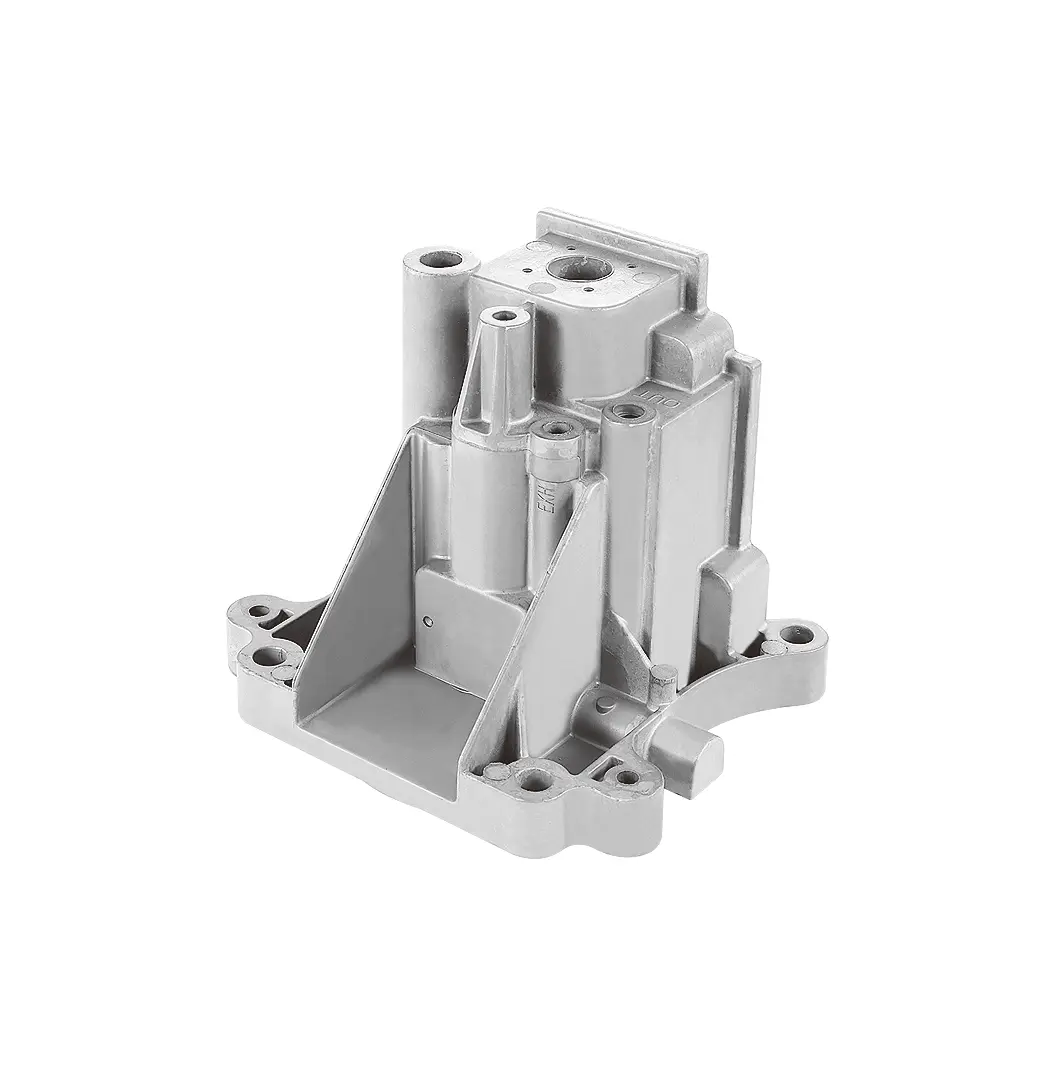

Aluminum Alloy Precision casting is widely used in the manufacture of engine parts, such as turbine blades, intake guide vanes and turbine disks. The precision casting process can produce parts of complex shapes and ensure their dimensional accuracy and surface quality, thereby improving the performance and efficiency of the engine. For example, the turbine disk is a key component that must have high strength and light weight because it needs to withstand extremely high temperatures and pressures. Aluminum alloy die casting is an ideal production process for producing high-quality, complex-shaped turbine disks.

(II) Aviation structural parts

Aluminum alloy precision casting technology can also be used to produce aviation structural parts, such as fuselage connectors, support structures and fuel tanks. Precision casting can reduce the weight of parts, improve the strength and rigidity of the structure, and give the aircraft better flight performance and fuel efficiency. For example, 44% of the weight of the fuselage of Airbus's A380 passenger aircraft is composed of aluminum alloy.

(III) Aerospace devices

Aluminum alloy precision casting also plays an important role in the manufacture of aerospace devices. For example, the manufacture of spacecraft thrusters, navigation components and landing devices. The precision casting process can ensure the accuracy and reliability of these devices and meet the strict requirements of space missions.

(IV) Satellite components

Aluminum alloy die castings have also been widely used in the manufacture of aerospace satellites and rocket parts. For example, the outer shell of a satellite is usually made of high-strength aluminum alloy die castings. In addition, thrusters and navigation equipment also need to use aluminum alloy die castings to ensure their lightness and durability.

3. Application cases of aluminum alloy castings in spacecraft

(I) Manufacturing technology and products of key components of light alloy series for spacecraft

The project has carried out research on the manufacturing technology of ultra-high strength and high-quality cast aluminum alloy tail cover and lower cone shell, ultra-long thin-walled homogeneous cast aluminum alloy cabin and complex integral cast aluminum alloy fuel tank, and cast magnesium alloy cabin for large and complex thin-walled key components of high-strength cast aluminum-magnesium alloy series for spacecraft. A series of new aluminum-magnesium alloy casting parts have been developed, including aluminum alloy tail cover, lower cone shell, ultra-long thin-walled homogeneous cabin, integral fuel tank, variable cross-section integral fuel tank, servo cabin, II-III stage interstage, II tail section, and magnesium alloy second cabin and fifth cabin shell. This technology has improved the level of high-quality casting manufacturing technology in my country and promoted technological progress in the industry.

(II) Breakthrough progress and industrial application of aviation aluminum alloy die-casting technology

In recent years, aviation aluminum alloy die-casting technology has made a series of major technological breakthroughs, providing a new lightweight solution for the aerospace field. Compared with traditional casting processes, modern aviation aluminum alloy die-casting technology has the following significant advantages: breakthroughs in material properties, with tensile strength reaching 450-550MPa, elongation increased to 8-12%, fatigue life increased by 3-5 times, and anisotropy reduced to below 10%; process innovation, using vacuum high-pressure die-casting technology (porosity <1%), semi-solid rheological die-casting (solid phase ratio 40-60%), ultra-low speed injection technology (0.05-0.1m/s), and local extrusion strengthening process; dimensional accuracy is improved, with dimensional tolerance reaching CT5 level, minimum wall thickness 0.8mm, surface roughness Ra1.6-3.2μm, and flatness 0.1mm/100mm.