+86-13516964051

+86-13516964051 Key Elements Affecting the Casting Performance of Aluminum Alloy Die Castings

Analysis of Key Elements Affecting the Casting Performance of Aluminum Alloy Die Castings

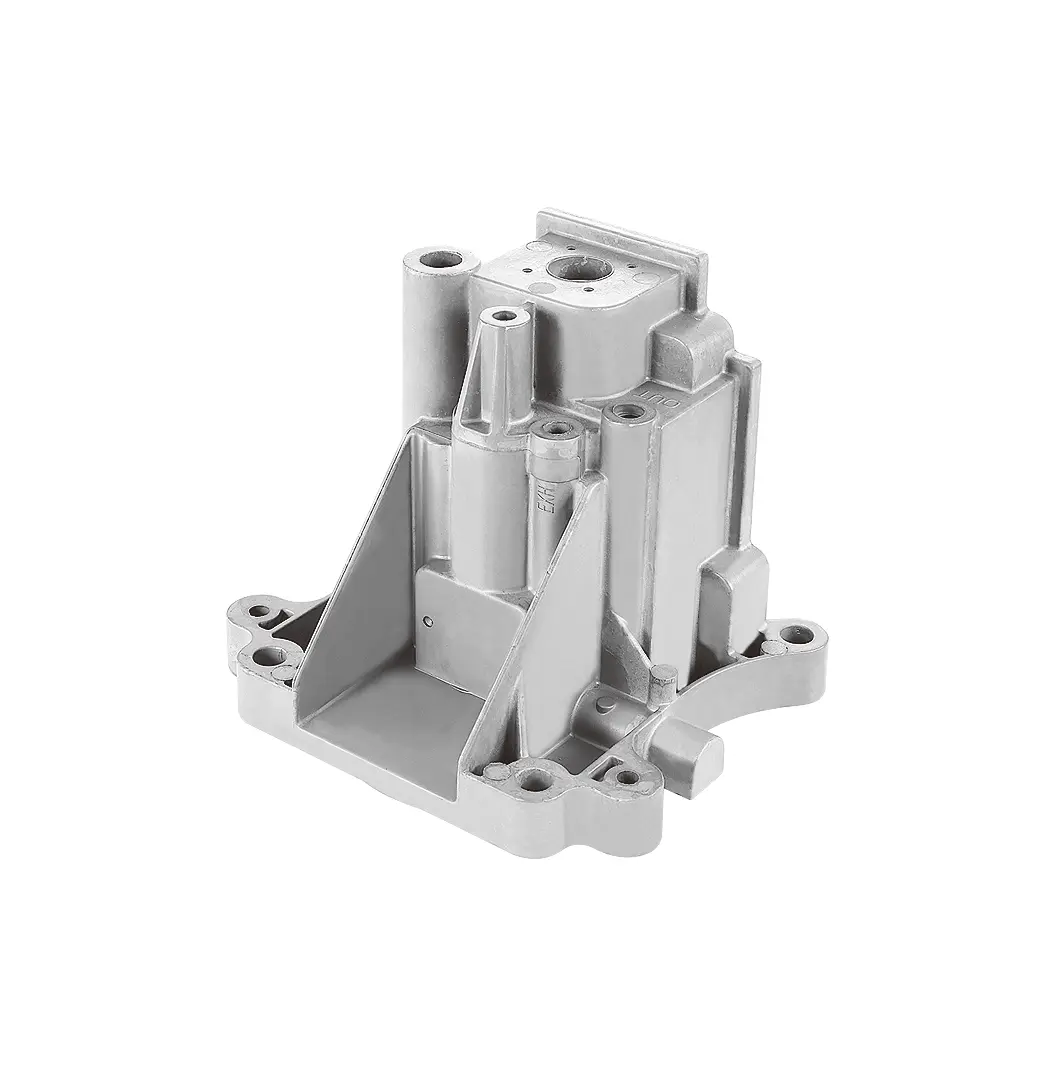

In modern industrial manufacturing, aluminum alloy die castings are widely used in numerous industries, including automotive, electronics, and medical devices, due to their advantages such as light weight, high strength, and excellent thermal conductivity. The quality and performance of aluminum alloy die castings are largely determined by their casting properties, which in turn are influenced by a variety of elements. This article will delve into the key elements that influence the casting performance of aluminum alloy die castings, providing a better understanding of the manufacturing process and key quality control points for aluminum alloy die castings.

Silicon: The Key to Improving Flowability

Silicon is an extremely important element in aluminum alloy die castings and has a significant impact on their casting properties. Within a certain silicon content range, aluminum alloys can effectively improve their flowability. This is because the eutectic formed by silicon in the alloy has a low melting point. During the Casting Process, the eutectic melts first, forming liquid channels that allow the molten alloy to more smoothly fill the mold cavity, reducing casting defects such as underfill and cold shuts.

Generally speaking, the silicon content of aluminum alloys used for die castings is typically between 6% and 12%. For example, the commonly used ADC12 aluminum alloy has a silicon content of approximately 9.6% to 12%, which gives it excellent fluidity and makes it ideal for die-casting complex parts. However, it's important to note that a higher silicon content isn't necessarily better. Excessive silicon content can lead to the formation of large coarse silicon particles in the alloy, increasing its brittleness, reducing the mechanical properties of the casting, and increasing mold wear.

Copper: A Balance Between Strength and Casting Performance

In aluminum alloy die-castings, copper primarily enhances alloy strength. Appropriate amounts of copper can form strengthening phases, such as CuAl₂, which can be dispersed within the aluminum matrix, enhancing the alloy's hardness and strength through precipitation strengthening.

However, the effect of copper on casting properties is complex. Low copper content has little effect on the alloy's fluidity and may even slightly improve it. However, as the copper content increases, the alloy's crystallization temperature range widens, reducing its fluidity and increasing the casting's tendency to hot cracking. Because alloys with a wide crystallization temperature range experience a longer solidification shrinkage during solidification, they are more likely to experience stress concentration within the casting, leading to hot cracking.

Therefore, in the production of aluminum alloy die-castings, the copper content must be controlled to balance strength and castability, typically within a range of 2% to 5%.

Magnesium: Improving Corrosion Resistance and Strength

Magnesium can form strengthening phases such as Mg₂Si in aluminum alloys, significantly increasing the alloy's strength and hardness. It also improves the alloy's corrosion resistance, which is particularly important for die-castings used in humid and corrosive environments.

However, the impact of magnesium on the casting properties of aluminum alloys should not be ignored. Excessive magnesium content can reduce the alloy's fluidity because magnesium easily forms high-melting-point compounds with other elements. These compounds can hinder the flow of the melt during casting. Furthermore, high magnesium content increases the alloy's gas absorption, leading to defects such as porosity in the casting. Therefore, in actual production, the magnesium content is generally controlled between 0.5% and 1.5% to ensure alloy strength and corrosion resistance while minimizing adverse effects on casting properties.

Iron: Controlling Content to Reduce Adverse Effects

Iron is often considered an impurity element in aluminum alloys, but its content can also affect casting properties. Low iron content can easily cause die sticking in aluminum alloy die castings, making mold cleaning more difficult, reducing production efficiency, and impairing the surface quality of the casting.

A moderate amount of iron can form intermetallic compounds such as FeAl₃ in the alloy. These compounds lubricate the mold and reduce die sticking. However, excessive iron content can lead to the formation of large amounts of acicular or flaky iron phases in the alloy. These phases increase the alloy's brittleness, reduce the mechanical properties of the casting, and also affect the alloy's fluidity.

Therefore, the iron content in aluminum alloy die castings is generally controlled between 0.5% and 1.2% to balance its effects on die sticking and mechanical properties. Influence of Other Elements

In addition to the main elements mentioned above, aluminum alloys may also contain other elements such as manganese, zinc, and nickel, which also have a certain impact on casting properties.

Manganese can refine the aluminum alloy's grain size, improving its strength and toughness, while having little effect on its fluidity. Zinc can improve its fluidity, but excessive levels can reduce its corrosion resistance. Nickel can enhance its high-temperature strength and corrosion resistance, but it can increase its brittleness and reduce its fluidity.

In actual production, the content of these elements must be properly controlled based on specific application requirements and casting processes to ensure that aluminum alloy die-castings have excellent casting and performance properties.

Synergy Between Elements

The various elements in aluminum alloys do not affect casting properties in isolation; complex synergies exist between them. For example, the combination of silicon and copper can compensate for their respective deficiencies to a certain extent. Silicon improves fluidity, while copper enhances strength. Together, they achieve a good balance between casting and mechanical properties. The combined effect of magnesium and silicon can form more Mg₂Si strengthening phases, further enhancing the alloy's strength. However, the ratio of these two elements must be carefully considered to avoid a significant negative impact on fluidity.

Therefore, when designing aluminum alloy compositions, it's important to consider not only the impact of individual elements but also the synergistic effects between them. Through a balanced combination, the casting and overall performance of aluminum alloy die-castings can be optimized.

The Impact of Process Factors on Element Effects

It's worth noting that the impact of elements on the casting performance of aluminum alloy die-castings is also affected by the casting process. For example, changes in process parameters such as die-casting temperature, mold temperature, and injection speed can alter the distribution and effects of elements in the alloy.

Higher die-casting temperatures can improve alloy fluidity, partially compensating for fluidity deficiencies caused by certain elements. However, they can also increase the alloy's gas absorption and oxidation tendency. Appropriate mold temperatures promote solidification and crystallization, reducing casting defects. However, excessively high or low mold temperatures can adversely affect casting quality. Therefore, in actual production, it's necessary to closely integrate alloy composition with the casting process. By optimizing process parameters, the positive effects of each element can be fully utilized while their negative effects can be minimized, thereby producing high-quality aluminum alloy die-castings.

In short, numerous elements influence the casting performance of aluminum alloy die-castings, and they interact and influence each other. During production, it's necessary to rationally design the alloy composition based on specific product requirements, strictly control the content of each element, and combine it with optimized casting processes to ensure excellent casting and performance of aluminum alloy die-castings. Yongkang Hantai Industry and Trade Co., Ltd., with its factories in Yongkang and a new factory in Jiangshan, Quzhou, fully understands the importance of element control and process optimization for the quality of aluminum alloy die-castings and remains committed to providing customers with high-quality aluminum alloy die-castings.