+86-13516964051

+86-13516964051 How to find a high-quality aluminum alloy low-pressure casting supplier?

How to find a high-quality aluminum alloy low-Pressure Casting supplier? Hantai Industry & Trade offers expert answers.

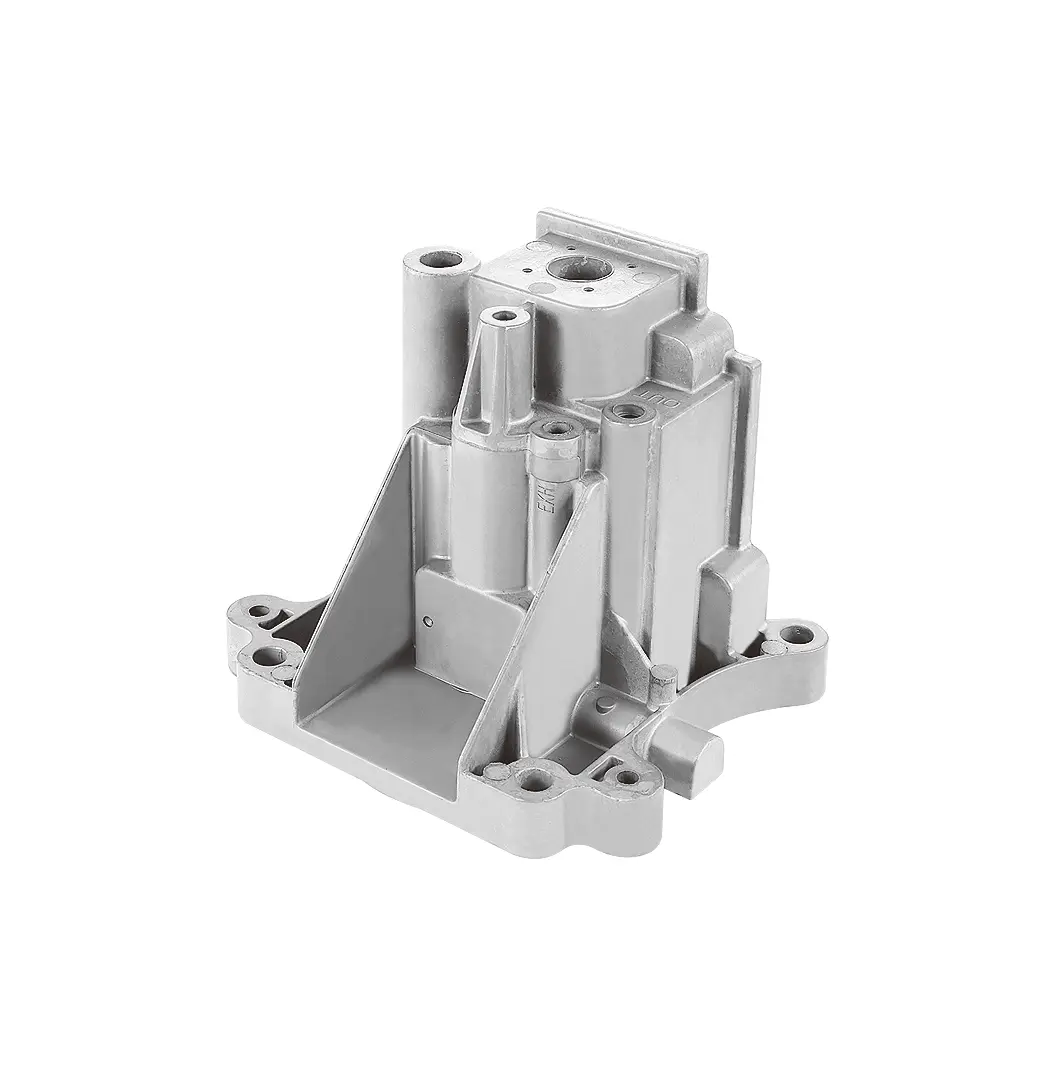

In the precision manufacturing industry, aluminum alloy low-pressure casting, with its high casting density, excellent dimensional accuracy, and superior mechanical properties, has become a core process in high-end industries such as automotive, medical devices, and aerospace. However, the qualifications of suppliers vary widely, making identifying high-quality partners a key challenge for many companies in their procurement decisions. As a professional manufacturer with many years of experience in the aluminum alloy low-pressure casting field, Yongkang Hantai Industry & Trade Co., Ltd. (hereinafter referred to as "Hantai Industry & Trade") draws on its operational experience at its Yongkang and new factories in Jiangshan, Quzhou, to explain the rationale behind selecting high-quality suppliers.

1. Examining Core Production Capabilities to Build a Solid Foundation for Quality

The core competitiveness of a high-quality aluminum alloy low-pressure casting supplier is primarily reflected in its hardware facilities and production scale. Hantai Industry & Trade's existing factory in Yongkang boasts over 10 years of mature production experience and is equipped with over 20 advanced low-pressure casting machines, enabling full-scale, in-house production from mold design to finished product processing. The new factory in Jiangshan, Quzhou, scheduled for operation in 2024, features industry-leading automated production lines, increasing the daily production capacity of a single line to three times that of traditional equipment. A constant-temperature workshop design ensures casting dimensional tolerances within ±0.05mm, meeting the stringent requirements for high-Precision Parts.

When evaluating suppliers, companies should focus on three key criteria: First, the advanced equipment, including whether it features fully automatic pouring systems and real-time temperature monitoring; second, production capacity flexibility, including the ability to quickly adjust production plans based on order demand. For example, Hantai Industry & Trade can flexibly deliver batches of 500-10,000 pieces; and third, quality inspection capabilities, including the availability of specialized testing equipment such as coordinate measuring machines and metallographic analyzers, to ensure a consistent 99.5% or higher pass rate for each batch.

2. Review the Technical R&D Team and Understand the Core Process

The quality differences in aluminum alloy low-pressure castings are essentially differences in technical strength. Hantai Industry & Trade has assembled a R&D team of 15 senior engineers, five of whom have over 10 years of industry experience and have led the process development for high-Precision Castings such as automotive engine blocks and medical device brackets. The team invests 8% of annual sales in technological innovation and has been granted 12 utility model patents, establishing a technological barrier in areas such as thin-walled castings and casting of complex internal structures.

When selecting suppliers, companies should thoroughly evaluate their technical team configuration, R&D investment ratio, and past success stories. For example, Hantai Industry & Trade customized motor housings for a new energy vehicle company. By optimizing the mold exhaust system and pouring process parameters, they reduced the casting scrap rate from the industry average of 8% to below 3%, demonstrating the direct transformation of technical strength into production efficiency.

3. Evaluate Supply Chain Management to Ensure Delivery Efficiency

A stable supply chain is a prerequisite for continuous supply. Hantai Industry & Trade has established a comprehensive management system encompassing raw material procurement, production scheduling, and logistics distribution. It has signed long-term cooperation agreements with three major aluminum alloy ingot manufacturers to ensure sufficient raw material inventory. It has introduced a manufacturing execution system (MES) to monitor production progress in real time and dynamically adjust production schedules based on order priorities. Warehousing centers have been established in Yongkang and Jiangshan, and through collaboration with logistics partners such as SF Express and Deppon, delivery within 48 hours in the Jiangsu, Zhejiang, and Shanghai regions, and within 72 hours nationwide.

For sourcing companies, the supplier's supply chain responsiveness is crucial. For example, Hantai Industry & Trade once faced an urgent order for 500 special-shaped castings within seven days. The company activated its emergency production plan, coordinated with raw material suppliers to prioritize supply, and adjusted production line shifts, ultimately completing delivery one day ahead of schedule, demonstrating its strong supply chain resilience.

4, Consider the After-Sales Service System to Resolve Worries

Complete after-sales service is the continuation of a successful partnership. Hantai Industry & Trade has established a "three-in-one" after-sales service standard: responding to customer feedback within two hours and proposing a solution within 24 hours; offering unconditional returns and exchanges for products with confirmed quality issues, including round-trip shipping costs; and regularly visiting customers to collect improvement suggestions during use and incorporate them into product iteration and optimization plans.

A medical device customer reported minor scratches on the surface of a casting. Hantai Industry & Trade's after-sales team responded to the site the next day and, upon inspection, discovered that the cause was a fixture used during assembly. The company not only provided free surface repair services but also assisted the customer in refining the fixture design to prevent the problem from recurring. This exceptional service has earned the customer's long-term trust.

From the stable operation of its Yongkang factory to the technological upgrades of its new Jiangshan plant, Hantai Industry & Trade has consistently adhered to the principle of "Professional Casting Quality, Service That Earns Trust" and has continued to deepen its presence in the field of aluminum alloy low-pressure casting. Companies seeking high-quality suppliers should consider a comprehensive assessment of hardware capabilities, technical reserves, supply chain management, and after-sales service to find a truly suitable partner. Hantai Industry and Trade looks forward to using its professional capabilities to become a reliable aid to your career development and jointly promote the high-quality development of the manufacturing industry.