+86-13516964051

+86-13516964051 How to control the thermal conductivity of alloy materials during low-pressure casting

How to control the thermal conductivity of alloy materials during low-Pressure Casting

Introduction

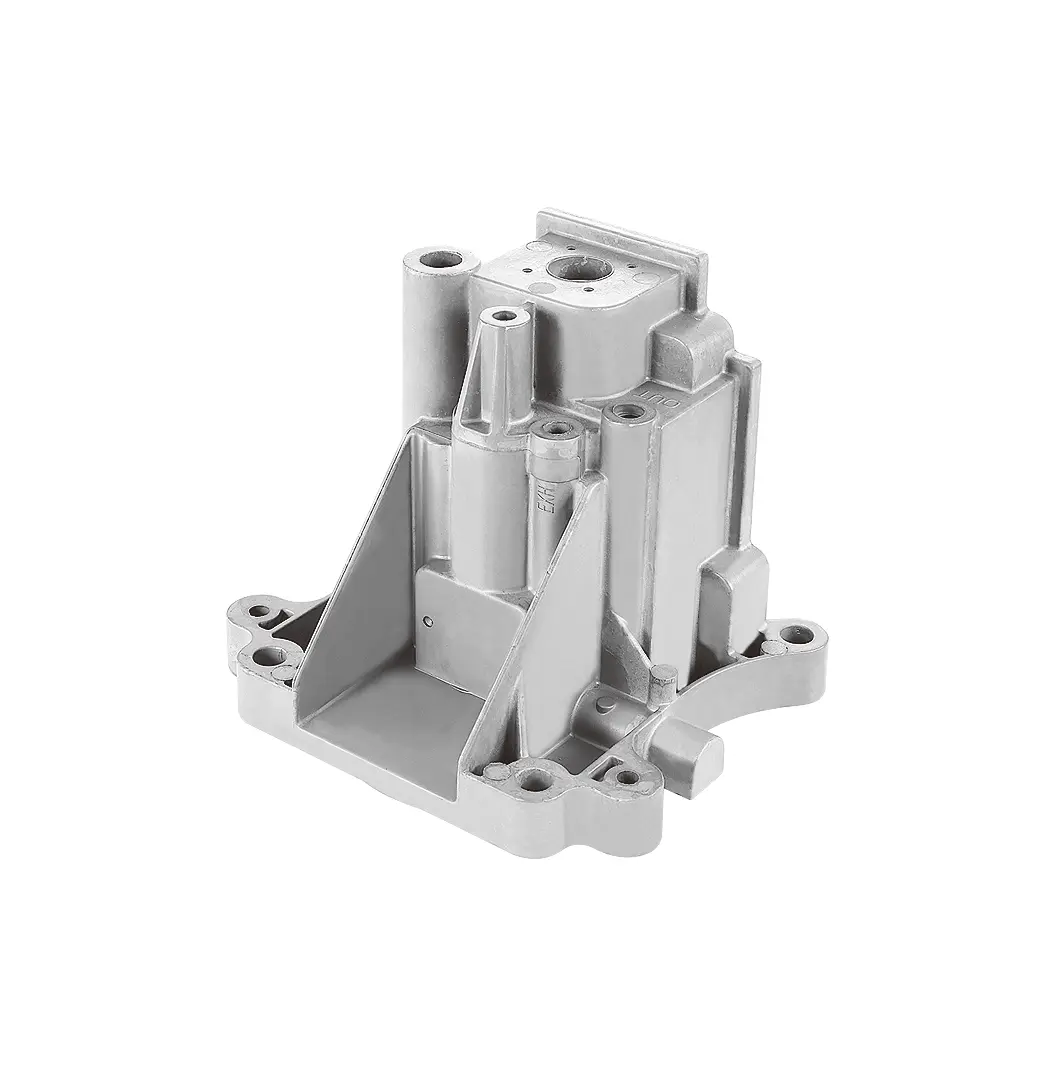

Low-pressure casting is an advanced Metal Casting Process. It is widely used in aerospace, automobile, machinery manufacturing and other fields because it can produce high-quality and complex-shaped castings. Aluminum alloy, as one of the commonly used materials inlow-pressure casting, has the advantages of light weight, high strength and corrosion resistance. However, in some specific application scenarios, such as radiators and engine parts, higher requirements are placed on the thermal conductivity of aluminum alloys. This article will explore in depth how to effectively control the thermal conductivity of alloy materials through various means during low-pressure casting to meet the needs of different customers.

I. Basic knowledge of thermal conductivity of alloy materials

(I) Definition and importance of thermal conductivity

Thermal conductivity refers to the ability of a material to transfer heat, which is usually measured by thermal conductivity (Thermal Conductivity), with the unit of W/(m·K). In low-pressure cast aluminum alloy products, good thermal conductivity is essential to improve product performance and efficiency. For example, in the cylinder head, piston and other parts of the automobile engine, heat needs to be dissipated in time to ensure the normal operation of the engine and extend its service life; in the radiator of electronic equipment, efficient thermal conductivity can effectively reduce the operating temperature of electronic components and improve the stability and reliability of the equipment.

(II) Factors affecting the thermal conductivity of aluminum alloys

Alloy elements and phase composition: Different alloy elements have different solid solubility in the aluminum matrix and the different phases formed, which will affect the degree of lattice distortion and thus change the thermal conductivity. Generally speaking, the presence of alloy elements will reduce the thermal conductivity of aluminum alloys to varying degrees. For example, in traditional Al-Si alloys, as the silicon content increases, the thermal conductivity of the alloy will decrease.

Impurities and defects: Impurity elements and defects (such as pores, inclusions, etc.) in the alloy will seriously hinder the transfer of heat and reduce thermal conductivity. Impurity atoms will interfere with the movement of free electrons in the aluminum matrix, increase the scattering effect, and reduce the number of free electrons for effective heat transfer; defects will reduce the density of the material, and heat will easily scatter and reflect at the defects during the transfer process, thereby reducing thermal conductivity.

Heat Treatment process: Heat treatment can affect the thermal conductivity by changing the phase structure, grain size and uniformity of the alloy. Appropriate heat treatment can optimize the microstructure of the alloy, reduce the precipitation of unfavorable phases and impurity segregation at the grain boundaries, and improve the overall thermal conductivity of the material.

2. Methods for controlling the thermal conductivity of alloy materials during low-pressure casting

(I) Optimizing alloy composition design

Choosing a suitable matrix alloy: According to the specific requirements of the product and the use environment, choose a basic aluminum alloy with good thermal conductivity. For example, for heat dissipation components that require higher thermal conductivity, the thermal conductivity of pure aluminum is higher, and it is possible to consider increasing the content of pure aluminum appropriately; for applications that require both strength and thermal conductivity, Al-Cu series, Al-Mg series and other alloys can be selected, and the performance can be balanced by optimizing the ratio of other alloy elements.

Adding microalloying elements: By adding a small amount of microalloying elements, such as Zn, Mn, Ti, etc., the grains of the alloy can be refined, the organizational structure can be improved, and thus the thermal conductivity can be improved. For example, the addition of Zn can improve the strength of aluminum alloy to a certain extent, while having relatively little effect on thermal conductivity, and can also optimize the heat conduction path by forming beneficial phases.

Control the content of impurity elements: strictly control the impurity elements in the alloy, such as Fe, Si, etc. Use high-purity raw materials and take effective refining measures during the smelting process to reduce the introduction of impurities. For example, Fe will form harmful β-AlFeSi phase in aluminum alloy, which will reduce the thermal conductivity and mechanical properties of the alloy, so the Fe content needs to be controlled at a low level.

(II) Accurate control of smelting process

Melting temperature control: reasonably select the smelting temperature to avoid excessively high or low temperatures that have adverse effects on the alloy composition and structure. Excessively high smelting temperatures may cause burning and oxidation of alloy elements and increase the impurity content; while excessively low temperatures will cause incomplete melting of the alloy and affect the uniformity of the composition. Generally, the smelting temperature of aluminum alloy is between 700℃-750℃, and the specific temperature should be adjusted according to the alloy composition and equipment conditions.

Melting time control: Control the melting time to ensure that the alloy components are fully melted and evenly distributed, but prevent the segregation of alloy elements and grain coarsening caused by long-term melting. During the melting process, the operation should be carried out according to a certain process flow, and the order of adding materials and stirring time should be reasonably arranged to make the alloy reach a good melting state. The general melting time is about 1-2 hours.

Refining and degassing treatment: Use advanced refining and degassing technologies, such as inert gas refining (argon, nitrogen, etc.), vacuum degassing, etc., to remove gases (hydrogen, etc.) and inclusions in the alloy. During the refining process, the introduction of inert gas can form bubbles, which absorb and take away the oxidized inclusions and hydrogen in the alloy during the rising process, thereby reducing the generation of pores and inclusions and improving the density and thermal conductivity of the alloy.

(III) Optimization of low-pressure casting process parameters

Liquid rising speed control: During the low-pressure casting process, the liquid rising speed should be moderate. Too fast a liquid rising speed will cause eddy currents in the metal liquid during the rising process, entraining air and impurities into the mold cavity, forming pores and oxidation inclusions; while too slow a liquid rising speed will cause the metal liquid to cool too quickly during the rising process, affecting the filling effect and the quality of the casting. Generally, the liquid rising speed is controlled between 0.5-2mm/s, and the specific speed should be adjusted according to the shape, size and fluidity of the casting.

Filling pressure control: Select the appropriate filling pressure to ensure that the metal liquid can fill the casting cavity smoothly and evenly. Too high a filling pressure will cause the metal liquid to impact the cavity wall, produce splashes and oxidation inclusions, and also cause greater internal stress inside the casting, affecting the thermal conductivity; while too low a filling pressure will cause defects such as incomplete filling and cold shut in the casting. The filling pressure is generally between 20-80kPa, and the specific pressure should be optimized according to factors such as the complexity of the casting, wall thickness and fluidity of the alloy.

Holding time control: Reasonably control the holding time to ensure that the casting can obtain sufficient shrinkage compensation pressure during the solidification process, and reduce the occurrence of defects such as shrinkage and shrinkage cavities. If the holding time is too short, the casting will not be fully compensated during the solidification process, resulting in internal looseness and increased porosity, and reduced thermal conductivity; while if the holding time is too long, the internal stress of the casting will increase, affecting its mechanical properties and thermal conductivity. The holding time is generally determined according to the size of the casting and the solidification characteristics of the alloy, usually between tens of seconds and a few minutes.

(IV) Appropriate heat treatment process

Solution treatment: Heat the aluminum alloy to a higher temperature (generally between 500℃-550℃), keep it warm for a certain period of time, so that the solute elements in the alloy are fully dissolved into the aluminum matrix to form a uniform solid solution. Solution treatment can improve the strength and toughness of the alloy, and it is also beneficial to subsequent aging treatment and improve the thermal conductivity of the alloy. However, it should be noted that the control of solution treatment temperature and time is very important. Too high or too long solution treatment will lead to grain coarsening and reduced supersaturation, which will affect thermal conductivity.

Aging treatment: The alloy after solution treatment is kept at a lower temperature (generally between 150℃-200℃) to precipitate the solute elements in the alloy in the form of fine particles to form a dispersed strengthening phase, thereby improving the strength and hardness of the alloy. Appropriate aging treatment can optimize the microstructure of the alloy, reduce impurity segregation and defects at the grain boundary, and improve thermal conductivity. However, the temperature and time of aging treatment also need to be precisely controlled to avoid over-aging or under-aging, which will affect the performance of the alloy.

3. Methods for testing and evaluating the thermal conductivity of alloy materials

(I) Direct measurement method of thermal conductivity

Steady-state method: including the guarded heat plate method, the spherical ball method, etc. The guarded heat plate method is to make the material to be tested into a flat sample of a certain size, place it between two guarded heat plates, and calculate the thermal conductivity by measuring the temperature difference and heat flow on both sides of the sample. This method has high measurement accuracy, but the sample preparation requirements are strict and the measurement time is long. It is suitable for research and testing of materials with high thermal conductivity requirements.

** transient method **: such as laser flash method. This method emits a short pulse laser to the sample surface to heat the sample surface instantly, and then measures the temperature change curve on the back of the sample, and uses mathematical methods such as Fourier transform to calculate the thermal diffusivity and thermal conductivity. The laser flash method has the advantages of fast measurement speed and wide application range. It can quickly and accurately measure the thermal conductivity of materials, especially for measurements in high temperature environments.

(II) Indirect evaluation method

Relationship between resistivity and thermal conductivity: According to the Wiedemann-Franz law, there is a certain relationship between the thermal conductivity and electrical conductivity of metal materials, that is, the ratio of thermal conductivity to electrical conductivity is proportional to temperature. Therefore, the thermal conductivity of alloy materials can be indirectly evaluated by measuring the resistivity (or electrical conductivity) of alloy materials and combining this law. This method is simple to operate and fast, but it should be noted that the applicability of this law in different materials and temperature ranges is different, and certain corrections and verifications are required.

Evaluation through performance testing and actual application: In actual low-pressure casting production, indirect evaluation can also be carried out through performance testing and actual application performance of castings. For example, for products such as radiators, the thermal conductivity of alloy materials can be judged by testing their heat dissipation effect, temperature distribution and other performance indicators to determine whether they meet the requirements; for engine parts, the impact of thermal conductivity on product performance can be evaluated through indicators such as engine operating performance and thermal efficiency.

4. Case analysis

(I) Low-pressure casting case of a certain automobile engine cylinder head

A certain automobile manufacturing company needs to produce a high-performance aluminum alloy engine cylinder head, which requires it to have good thermal conductivity and high strength. In the production process, the Al-Si-Cu-Mg alloy was selected by optimizing the alloy composition design, and the content of impurity element Fe was strictly controlled below 0.5%; in the smelting process, argon refining technology was used to control the hydrogen content below 0.1ml/100gAl; in the low-pressure casting process, the liquid rise speed was controlled to 1.2mm/s, the filling pressure was 40kPa, and the holding time was 60s; finally, appropriate solution treatment and aging treatment were carried out. After a series of control measures, the thermal conductivity of the produced engine cylinder head reached more than 120W/(m·K), which met the design requirements and effectively improved the heat dissipation effect and reliability of the engine.

(II) Low-pressure casting case of an electronic radiator

An electronic equipment manufacturing company needs an aluminum alloy radiator with high thermal conductivity, requiring a thermal conductivity of not less than 150W/(m·K). In the production process, high-purity aluminum is used as the basis, and appropriate amounts of Cu, Mn and other elements are added to optimize the thermal conductivity and mechanical properties of the alloy; in the smelting process, the smelting temperature and time are strictly controlled, and vacuum degassing and refining processes are used to ensure the purity of the alloy; in the low-pressure casting process, the mold design and process parameters are optimized so that the molten metal can evenly fill the cavity and reduce the generation of internal defects; at the same time, the castings are cold rolled, heat treated and other processing processes to further improve the thermal conductivity of the material. The thermal conductivity of the heat sink finally produced reaches 160W/(m·K), which meets the heat dissipation requirements of electronic equipment and ensures the stable operation of the equipment.

5. Conclusion

In the low-pressure casting process, controlling the thermal conductivity of alloy materials is a systematic project, which requires comprehensive consideration and optimization from multiple aspects such as alloy composition design, smelting process, casting process and heat treatment process. By reasonably selecting alloy elements, strictly controlling impurity content, accurately controlling smelting and casting parameters, and adopting appropriate heat treatment processes, the thermal conductivity of aluminum alloys can be effectively improved to meet the performance requirements of different customers for products. At the same time, choosing appropriate testing and evaluation methods to accurately measure and judge the thermal conductivity of alloy materials is also an important means to ensure product quality and performance.