+86-13516964051

+86-13516964051 Exploring the Diverse Applications of Aluminum Alloy High-Pressure Die Casting

Exploring the Diverse Applications of Aluminum Alloy High-Pressure Die Casting

Within the vast landscape of modern manufacturing, aluminum alloy high-pressure die casting, with its unique advantages, has become a key technology for product optimization and innovation in numerous industries. This technology, by rapidly injecting molten aluminum alloy into precision molds under high pressure, efficiently produces castings with high precision, high strength, and excellent surface quality, providing exceptional solutions for various industries.

Automotive Industry: Driving Efficiency and Safety Transformation

The automotive industry is undoubtedly a key application area for aluminum alloy high-pressure die casting. In the current pursuit of energy conservation, emission reduction, and high performance, lightweighting has become a key industry trend, and aluminum alloy high-pressure die castings play a crucial role in this area.

As a core component of an automobile, the performance of the engine directly impacts the overall performance of the vehicle. Aluminum alloy high-pressure die casting is used to manufacture key components such as engine blocks and cylinder heads. The low density of aluminum alloy effectively reduces engine weight and lowers vehicle energy consumption. Furthermore, high-pressure die casting imparts excellent strength and density to the castings, ensuring stable operation under the harsh operating conditions of high temperature and pressure, thereby improving power output efficiency. For example, a well-known automobile brand has reduced engine weight by approximately 20% and improved fuel economy by over 10% by adopting an aluminum alloy high-pressure die-cast cylinder block.

Automotive safety performance is crucial to the safety of drivers and passengers. Aluminum alloy high-pressure die-cast body components, such as A-pillars, B-pillars, and door impact beams, offer high strength and excellent energy absorption properties. They effectively disperse and absorb energy in collisions, providing reliable protection for occupants. Experimental data shows that vehicles equipped with aluminum alloy high-pressure die-cast safety components can reduce cockpit deformation by 15%-20% in frontal impact tests, significantly improving the vehicle's passive safety performance.

The chassis system is crucial to a vehicle's handling stability. Aluminum alloy high-pressure die-cast chassis components, such as suspension control arms and steering knuckles, reduce weight while maintaining excellent rigidity and toughness, optimizing vehicle handling and ensuring a smoother and more agile ride.

Electronics Industry: Powering Breakthroughs in Thinness and High Performance

As electronic products evolve towards thinner, lighter, and more high-performance designs, aluminum alloy high-pressure Casting Technology is bringing innovative possibilities to the electronics industry.

In the smartphone market, aluminum alloy high-pressure casting is used to manufacture components such as phone casings and mid-frames. High-pressure casting enables high-precision molding of complex structures, giving phones a more refined and streamlined appearance while also meeting the demand for thinness and lightness. Aluminum alloy's excellent heat dissipation properties quickly dissipate heat generated within the phone, effectively reducing the body temperature, ensuring stable operation of core components such as chips, and improving the phone's overall performance and lifespan. For example, a flagship phone brand's use of a high-pressure cast aluminum alloy casing reduced its thickness by 0.5mm and increased heat dissipation efficiency by 20%, effectively preventing lags caused by overheating.

For laptops, aluminum alloy high-pressure cast casings not only provide sturdy protection but also impart a stylish, high-end appearance. Furthermore, the high-pressure Casting Process enables the design of complex heat dissipation fin structures within the casing, enhancing heat dissipation and ensuring unimpaired performance under prolonged, high-load operation. Aluminum alloy high-pressure castings are also widely used in other electronic products, such as tablets and smartwatches, for components such as housings and brackets, providing strong support for product lightweighting and high performance.

Aerospace Industry: Embarking on the Journey of Lightweighting and Reliability

The aerospace industry places extremely stringent demands on material properties. Aluminum alloy high-pressure casting, with its outstanding comprehensive performance, has become an indispensable manufacturing technology in this field.

Aircraft engines, as the "heart" of an aircraft, demand extremely high component quality and performance. Aluminum alloy high-pressure casting is used to manufacture engine components such as fan blades, compressor blades, and casings. These components operate in extreme environments of high temperature, high pressure, and high speed, requiring lightweight, high strength, high-temperature resistance, and corrosion resistance. Aluminum alloy high-pressure castings meet these requirements, effectively reducing engine weight, improving thrust-to-weight ratio, lowering fuel consumption, and enhancing aircraft flight performance and range. According to statistics, engines using aluminum alloy high-pressure casting components can reduce overall weight by 10%-15% and reduce fuel consumption by 8%-10%. Aircraft fuselage structural components, such as wing spars and fuselage frames, are manufactured using aluminum alloy high-pressure casting technology. This achieves lightweighting while maintaining structural strength and reliability. This not only helps increase the aircraft's load capacity but also reduces flight drag and improves flight efficiency. In the spacecraft industry, aluminum alloy high-pressure castings are used to manufacture components such as satellite structural frames and solar panel mounts, ensuring stable operation in the complex environment of space.

Industrial Equipment Industry: Builds Robustness and Durability

Industrial equipment is often subjected to significant pressure and loads during operation, placing extremely high demands on the strength and durability of its components. Aluminum alloy high-pressure casting technology provides an ideal solution for this.

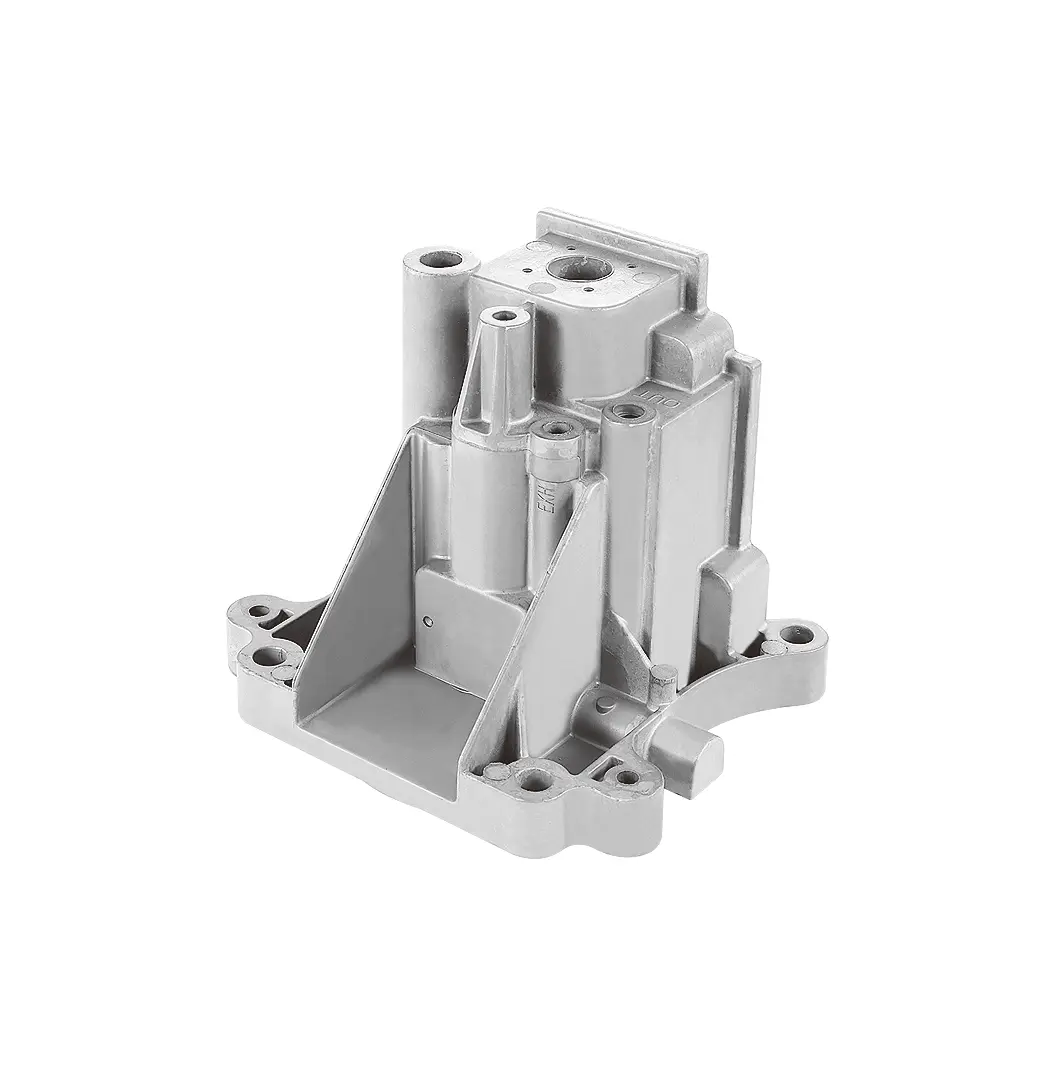

In the machinery manufacturing industry, aluminum alloy high-pressure casting is widely used in the manufacture of various mechanical components, such as gearbox housings, motor housings, pump bodies, and valves. High-pressure cast gearbox housings offer excellent sealing and high strength, effectively protecting the internal gear transmission system, reducing noise and vibration, and improving mechanical transmission efficiency and service life. The motor housing is made of high-pressure die-cast aluminum alloy, which not only provides reliable protection for the motor but also improves its efficiency and stability due to its excellent heat dissipation.

In hydraulic and pneumatic equipment, pump bodies and valves made of high-pressure die-cast aluminum alloys feature highly precise internal dimensions and excellent surface quality, ensuring smooth delivery and precise control of liquids or gases, enhancing equipment performance and reliability. In industrial automation equipment, components made of high-pressure die-cast aluminum alloys, such as robot joints and manipulators, boast lightweight and high strength, enabling more flexible and precise operation, improving production efficiency and product quality.

Lighting Industry: Illuminating Efficient and Beautiful Design

The lighting industry places high demands on product heat dissipation and exterior design, and aluminum alloy high-pressure die-casting technology demonstrates unique advantages in this area.

In LED lighting fixtures, high-pressure die-cast aluminum alloys are used to manufacture components such as lamp housings and heat sinks. Aluminum alloy's excellent thermal conductivity allows it to quickly dissipate heat generated by LED chips, effectively reducing chip temperature and extending the life of LED lamps. High-pressure casting enables complex heat dissipation designs, such as fin-type heat sinks, significantly increasing the heat dissipation area and improving heat dissipation efficiency. Experimental data shows that LED lamps using aluminum alloy high-pressure casting heat sinks can reduce chip temperatures by 10-15°C and extend lamp life by 20-30%.

Also, aluminum alloy high-pressure casting can meet diverse design requirements for lighting fixtures. Using precision molds, it is possible to create a variety of elegantly shaped and sleek lamp housings, adding a touch of aesthetics and artistry to indoor and outdoor lighting environments. In some high-end lighting products, aluminum alloy high-pressure casting lamp housings can also undergo surface treatments such as anodizing and painting, further enhancing the product's quality and decorative effect.

Medical Device Industry: Ensuring the Need for Safety and Precision

The medical device industry has extremely stringent requirements for product quality, safety, and biocompatibility. Aluminum alloy high-pressure casting technology, due to its unique advantages, has found widespread application in this field.

In surgical instruments, aluminum alloy high-pressure casting is used to manufacture high-precision, high-strength instrument components, such as surgical scissor handles and tweezers chucks. These components require excellent mechanical properties to ensure precision and reliability during surgical procedures. After meticulous machining and surface treatment, aluminum alloy high-pressure castings meet the stringent surface quality and hygiene standards required of medical devices. Their lightweight design also reduces the burden on medical personnel.

In the medical device sector, aluminum alloy high-pressure casting is used in components such as housings and brackets for medical imaging equipment. These components must not only provide reliable protection for the delicate electronic components within, but also exhibit excellent stability and shock resistance. Aluminum alloy high-pressure castings meet these requirements. Furthermore, their excellent biocompatibility ensures that the equipment does not cause adverse reactions when in contact with the human body, thus ensuring patient safety.

In rehabilitation assistive devices, aluminum alloy high-pressure casting components, such as wheelchair frames and prosthetic joints, offer patients a more comfortable and convenient user experience with their high strength and lightweight design.

Sporting Goods Industry: Inspiring Innovation in Performance and Design

The sporting goods industry pursues high standards for lightweight, high strength, and design. Aluminum alloy high-pressure casting technology has injected new vitality into the innovative development of sporting goods. In the bicycle industry, aluminum alloy high-pressure casting is widely used in the manufacture of key components such as bicycle frames and wheel hubs. High-pressure cast bicycle frames achieve a lightweight design while maintaining high strength and rigidity, making riding easier and more maneuverable, and improving riding performance. For example, road bikes with high-pressure cast aluminum alloy frames can reduce overall weight by 1-2 kg, resulting in better climbing and acceleration performance. High-pressure casting of aluminum alloy wheel hubs not only improves wheel strength and fatigue resistance, but also optimizes aerodynamics and reduces riding resistance.

In golf equipment, aluminum alloy high-pressure casting is used to manufacture golf club heads. The high-pressure casting process precisely controls the weight distribution and internal structure of the club head, resulting in greater spring force and better directionality when impacting the ball, enhancing the player's shooting experience and performance. Aluminum alloy high-pressure castings are also used in the manufacture of racket frames and other components in other sporting goods, such as tennis and badminton rackets, providing athletes with superior performance. In addition, aluminum alloy high-pressure casting can also be used to manufacture fitness equipment components, such as dumbbell handles and exercise bike frames. Its high strength and aesthetically pleasing appearance meet consumer demands for quality and design.

Aluminum alloy high-pressure casting technology, with its superior performance and wide applicability, plays a vital role in numerous industries, including automotive, electronics, aerospace, industrial equipment, lighting, medical devices, and sporting goods, providing strong support for product upgrades and innovative development across these sectors.