+86-13516964051

+86-13516964051 Detailed explanation of the melting temperature of aluminum alloy high pressure casting

Detailed explanation of the melting temperature of aluminum alloy High Pressure Casting

Introduction

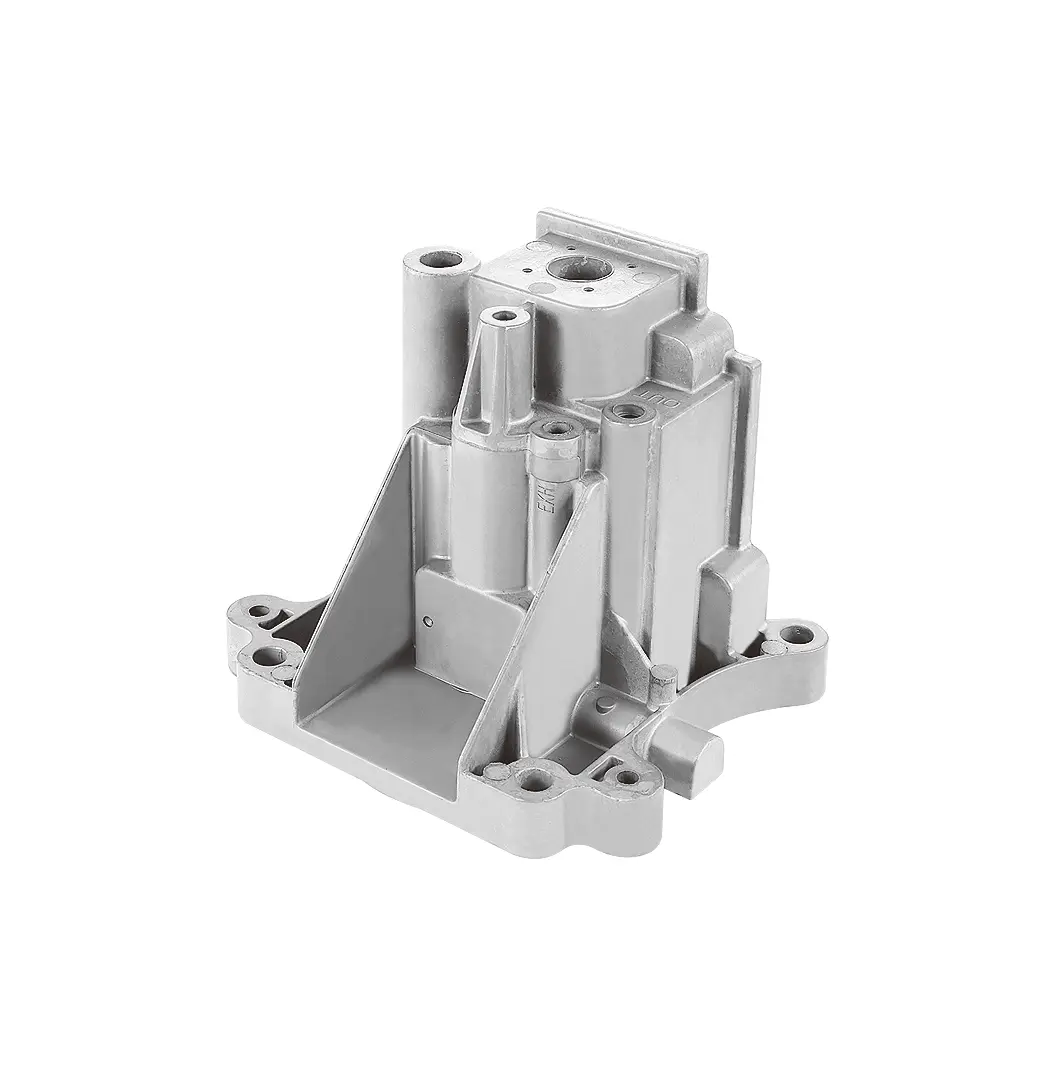

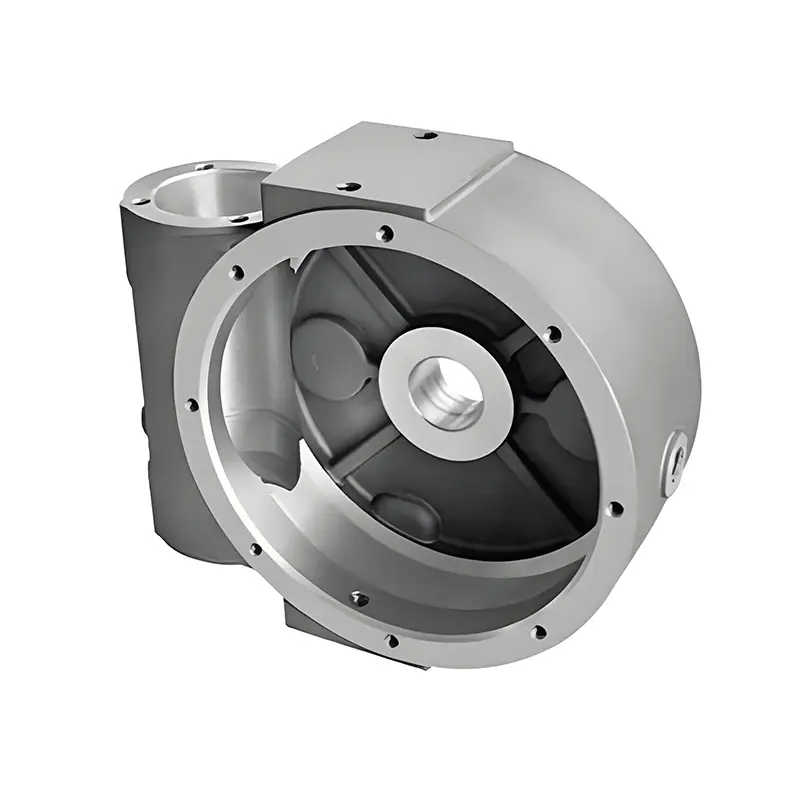

Aluminum alloy high pressure casting is an efficient metal forming process, which is widely used in many fields such as automobiles, aerospace, and electronic equipment. Its products have the advantages of high precision, good surface quality, and dimensional stability. In the process of aluminum alloy high pressure casting, the melting temperature is a crucial process parameter, which is directly related to the performance of the alloy, casting quality, and production efficiency. This article will explore the relevant knowledge of the melting temperature of aluminum alloy high pressure casting to help you better understand this key factor.

1. The range of melting temperature of aluminum alloy high pressure casting

General range: Generally, the melting temperature of aluminum alloy high pressure casting is between 650℃ and 750℃. In this temperature range, aluminum alloy can achieve a good melting effect, while also ensuring its fluidity and ability to fill the mold.

Specific range of different alloy components: For different aluminum alloy components, the melting temperature will vary. For example, for eutectic 4xxx alloys, when silicon is added in the form of intermediate alloy or crystalline silicon, the melting temperature should be controlled at 750℃~780℃; while for some conventional non-eutectic aluminum alloys, such as the commonly used ADC12, A380, etc., the melting temperature is generally around 700℃~740℃.

2. Factors affecting the melting temperature

Alloy elements and content: The type and content of alloy elements have a significant effect on the melting point and melting temperature of aluminum alloys. For example, aluminum-silicon alloys have a relatively low melting point due to their high silicon content, but in order to ensure that silicon can be fully dissolved and play its alloying role, the melting temperature usually needs to be appropriately increased. For aluminum alloys containing easily burned elements such as magnesium and copper, the melting temperature should not be too high to avoid excessive element burning, which will affect the performance and composition accuracy of the alloy.

Smelting equipment and process: Different melting equipment has different heating methods and thermal efficiencies, which will lead to differences in the control accuracy of the melting temperature. For example, when a natural gas melting and holding furnace is used to melt aluminum alloy, the melting temperature is generally controlled at 730℃~750℃, and the temperature control strategy needs to be reasonably adjusted according to the heating rate and heat loss of the equipment during the melting process. In addition, parameters such as the heating rate and holding time in the melting process will also affect the melting temperature and need to be optimized according to specific process requirements.

Casting requirements: The size, shape, wall thickness and quality requirements of the casting will affect the selection of melting temperature. For castings with complex shapes and thin walls, in order to ensure that the alloy can fully fill the mold cavity, it is usually necessary to appropriately increase the melting temperature to improve the fluidity and filling capacity of the alloy. For castings with larger sizes and thicker walls, the melting temperature can be relatively low to reduce the amount of air intake and oxidation burning of the alloy, and avoid defects such as shrinkage cavities and shrinkage.

Mold type and temperature: Factors such as the material, structure and preheating temperature of the mold will also have an indirect impact on the melting temperature of the aluminum alloy. If the mold temperature is low, the alloy will cool down quickly after entering the mold, which may affect its fluidity and cause problems such as incomplete filling. Therefore, in actual production, it is necessary to reasonably adjust the melting temperature according to the temperature and characteristics of the mold to ensure that the alloy has the appropriate temperature and fluidity when injected into the mold.

3. The influence of melting temperature on the performance of aluminum alloy

Mechanical properties: If the melting temperature is too high, the grains of the aluminum alloy will be coarse, resulting in a decrease in its mechanical properties, such as strength, toughness, elongation and other indicators will be affected. For example, when the melting temperature of the aluminum alloy exceeds 750℃, the grains begin to grow significantly, and the yield strength and tensile strength of the material decrease by about 15% and 10% respectively. On the contrary, if the melting temperature is too low, the alloy elements may not be fully dissolved and evenly distributed, and problems such as component segregation and uneven organization will occur, which will affect the mechanical properties of the alloy. The appropriate melting temperature can enable the alloy to obtain a fine and uniform grain structure, thereby improving its comprehensive mechanical properties.

Physical properties: Changes in melting temperature will affect the physical properties of aluminum alloys such as density, thermal conductivity, and thermal expansion coefficient. Too high a melting temperature may cause the density of the alloy to decrease, and the thermal conductivity will also decrease, which will affect the heat dissipation and solidification process of the casting. In addition, the thermal expansion coefficient of the alloy will increase with the increase of the melting temperature, and it is easy to produce internal stress and deformation during the cooling process of the casting, affecting the dimensional accuracy and shape stability of the casting.

Corrosion resistance: Inappropriate melting temperature may reduce the corrosion resistance of aluminum alloy. For example, too high a temperature may cause the oxide film structure on the surface of the alloy to be loose and incomplete, increasing the chance of corrosion of the alloy matrix by the corrosive medium. At the same time, if the temperature is not properly controlled during the melting process, impurity elements may be introduced or segregation may occur, which will become the source of corrosion and accelerate the corrosion process of the alloy.

4. Melting temperature control method

Adopt advanced temperature measuring equipment: Using high-precision thermocouples, infrared thermometers and other temperature measuring equipment, it can measure the temperature changes of aluminum alloys in real time and accurately during the melting process, providing reliable data support for temperature control. During the smelting process, the probe of the temperature measuring equipment needs to be placed in a suitable position to ensure that the measurement results can truly reflect the temperature of the melt, and the temperature measuring equipment needs to be calibrated and maintained regularly to ensure its measurement accuracy.

Optimize smelting process parameters: According to the composition of the aluminum alloy, the characteristics of the castings and the performance of the smelting equipment, reasonably determine the process parameters such as the heating rate and holding time of the smelting. For example, when smelting aluminum alloys containing easily burned elements such as magnesium and zinc, a lower heating rate should be used, and the high temperature holding time should be appropriately shortened to reduce the burning of the elements. At the same time, during the smelting process, large temperature fluctuations should be avoided and the temperature should be kept stable to ensure the quality and performance of the alloy.

Add appropriate modifiers and refining agents: During the smelting process, adding an appropriate amount of modifiers and refining agents can improve the smelting performance and organizational structure of the aluminum alloy, thereby reducing the strict requirements for the smelting temperature to a certain extent. For example, adding a modifier can refine the grains of the alloy and improve its mechanical properties and casting properties; refining agents can effectively remove gases and inclusions in the melt, reduce the alloy's air intake and oxidation loss, and improve the purity of the alloy.

Strengthen the monitoring and management of the smelting process: During the smelting process, a dedicated person should be arranged to monitor the temperature in real time. Once the temperature is abnormal, timely measures should be taken to adjust it, such as adjusting the heating power, adding cooling materials, etc. At the same time, the maintenance and maintenance of the smelting equipment should be strengthened to ensure the normal operation of the equipment and avoid temperature out of control due to equipment failure. In addition, production records should be kept, and the temperature, time, process parameters, etc. of each smelting should be recorded in detail for data analysis and quality traceability.

5. Relationship between smelting temperature and other process parameters

Relationship with pouring temperature: The pouring temperature refers to the temperature of the aluminum alloy liquid when it flows from the gate into the mold cavity, which is closely related to the smelting temperature. Under normal circumstances, the pouring temperature is about 30℃~50℃ lower than the smelting temperature. This is because after the alloy is smelted, there will be a certain amount of heat loss during the stirring, degassing, ladle transfer and other operations. At the same time, in order to ensure that the alloy has appropriate fluidity and filling capacity when entering the mold, and not to affect the quality of the casting due to excessive temperature, the pouring temperature needs to be properly controlled. For example, for aluminum alloys with a melting temperature of 730℃, the pouring temperature is generally controlled at around 700℃.

Relationship with mold temperature: The mold temperature has an important influence on the solidification rate and microstructure formation of aluminum alloys. It works together with the melting temperature to determine the quality of the casting. If the mold temperature is too low, the alloy will cool rapidly after entering the mold, resulting in poor fluidity and prone to defects such as cold shut and insufficient pouring. If the mold temperature is too high, the alloy will solidify slowly, increase the air intake and oxidation burning, and may cause shrinkage holes, shrinkage and other defects in the casting. Generally speaking, the mold temperature should be reasonably adjusted according to the melting temperature of the alloy and the characteristics of the casting, usually controlled between 150℃~300℃ to ensure that the alloy can solidify evenly in the mold and obtain high-quality castings.

Relationship with cooling rate: Cooling rate refers to the speed at which a casting cools from pouring temperature to room temperature, which is closely related to factors such as melting temperature and mold temperature. Different cooling rates will produce different organizational structures and properties of castings. Higher melting temperatures usually result in relatively slow cooling rates of castings, which is conducive to eliminating thermal stress in castings and reducing deformation and cracking tendencies. However, in some cases, slow cooling rates may also cause grain growth and reduce the mechanical properties of castings. Therefore, in the process of high-pressure casting of aluminum alloys, it is necessary to comprehensively consider factors such as melting temperature and mold temperature, and reasonably control the cooling rate to meet the quality requirements of castings.

6. Case analysis in actual production

Case 1: When a certain automobile parts manufacturer was producing aluminum alloy cylinder blocks, it was found that there were defects such as pores and pinholes on the surface of the castings. After analysis, it was found that the increase in the air intake of aluminum alloys was caused by the excessively high melting temperature. The company significantly improved the surface quality of castings by reducing the melting temperature from 750℃ to 720℃~730℃ and optimizing the degassing process. The defects such as pores and pinholes were significantly reduced, and the qualified rate of products increased by about 20%.

Case 2: When another aerospace parts manufacturer produced complex thin-walled aluminum alloy structural parts, due to the complex shape and thin wall thickness of the castings, it was difficult to fill them. The lower melting temperature of 680℃ was initially used, resulting in a large number of problems with filling dissatisfaction and unclear contours in the castings. Later, by increasing the melting temperature to 730℃~740℃ and appropriately adjusting the pouring system and mold temperature, the filling performance of the castings was effectively improved, and the surface quality and internal quality of the products met the design requirements and passed the customer acceptance smoothly.

7. Future Development Trend of Melting Temperature Control Technology for Aluminum Alloy High-Pressure Casting

Intelligent Temperature Control System: With the continuous development of industrial automation and intelligent technology, more and more intelligent temperature control systems will be adopted in future aluminum alloy high-pressure casting workshops. This system can monitor various parameters in the smelting process in real time, such as temperature, composition, flow rate, etc., and automatically analyze and control through advanced algorithms to achieve precise adjustment and stable control of the smelting temperature, improve production efficiency and product quality, and reduce manual intervention and production costs.

New heating technology and equipment: In order to meet the higher requirements of aluminum alloy high-pressure casting for smelting temperature control accuracy and energy efficiency, future heating technology and equipment will continue to innovate and develop. For example, new heating technologies such as induction heating and microwave heating have the characteristics of fast heating speed, high efficiency, and good temperature uniformity, and are expected to be more widely used in the field of aluminum alloy smelting. At the same time, the energy-saving and environmental protection performance of heating equipment will also be continuously optimized to meet the requirements of sustainable development.

Integration of temperature control and quality inspection: In the future, aluminum alloy high-pressure casting production will pay more attention to the close integration of quality control and inspection links with smelting temperature control. By integrating advanced online detection technologies such as spectral analysis and ultrasonic detection on smelting equipment, the composition and internal defects of aluminum alloys can be monitored in real time, and the smelting temperature and process parameters can be adjusted in time according to the detection results to achieve closed-loop control of the smelting process and ensure the stability and consistency of casting quality.

8. Conclusion

The melting temperature of aluminum alloy high pressure casting is a complex and critical process parameter. It is affected by many factors and has a profound impact on the performance of aluminum alloy and the quality of castings. By deeply understanding the range of melting temperature, influencing factors, control methods and the relationship with other process parameters, the aluminum alloy high pressure Casting Process can be better optimized to improve product quality and production efficiency. In actual production, enterprises should reasonably select and control the melting temperature according to their own production conditions and product requirements, and continuously explore and apply new temperature control technologies and methods to meet the market demand for high-quality aluminum alloy castings.