+86-13516964051

+86-13516964051 Common defects and prevention of low-pressure casting

Common defects and prevention of low-Pressure Casting

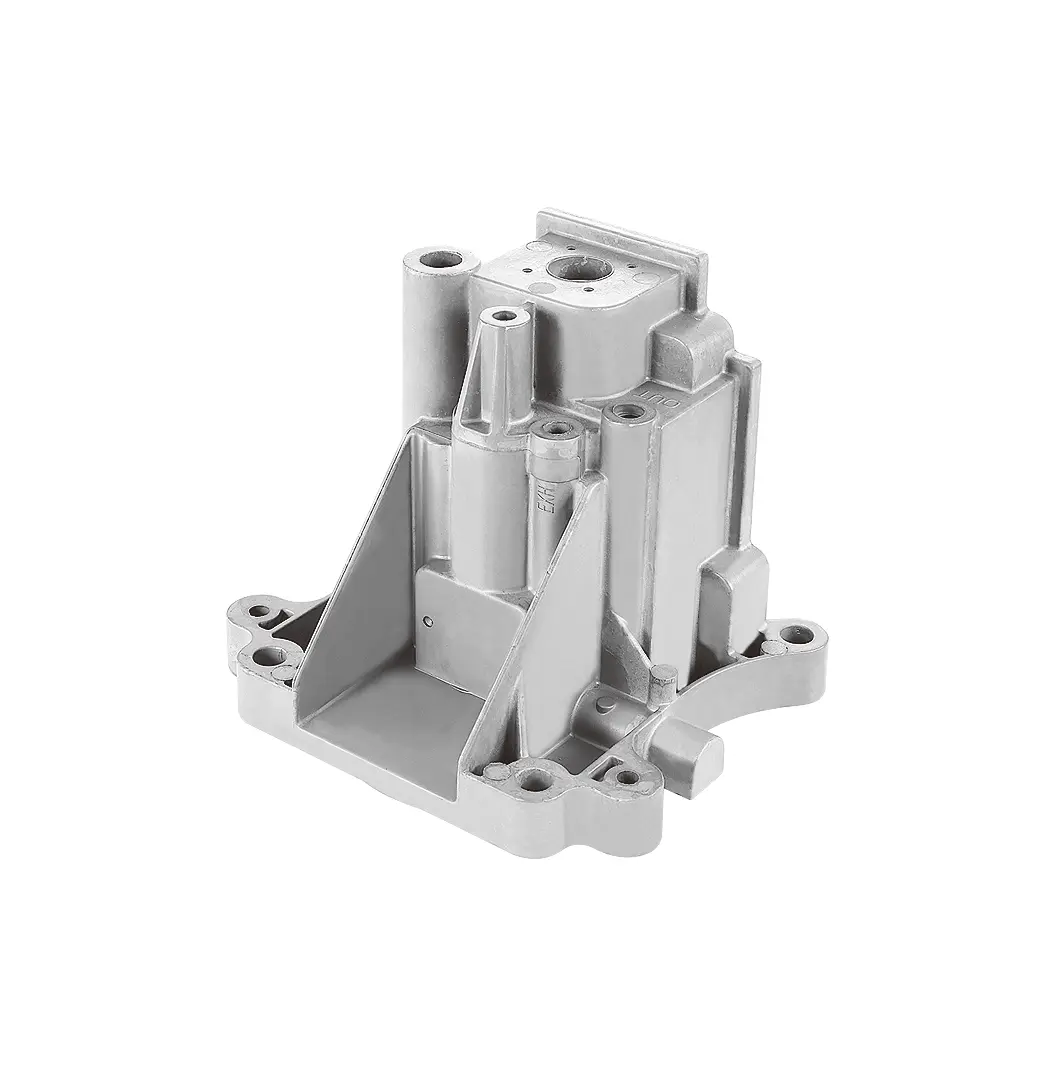

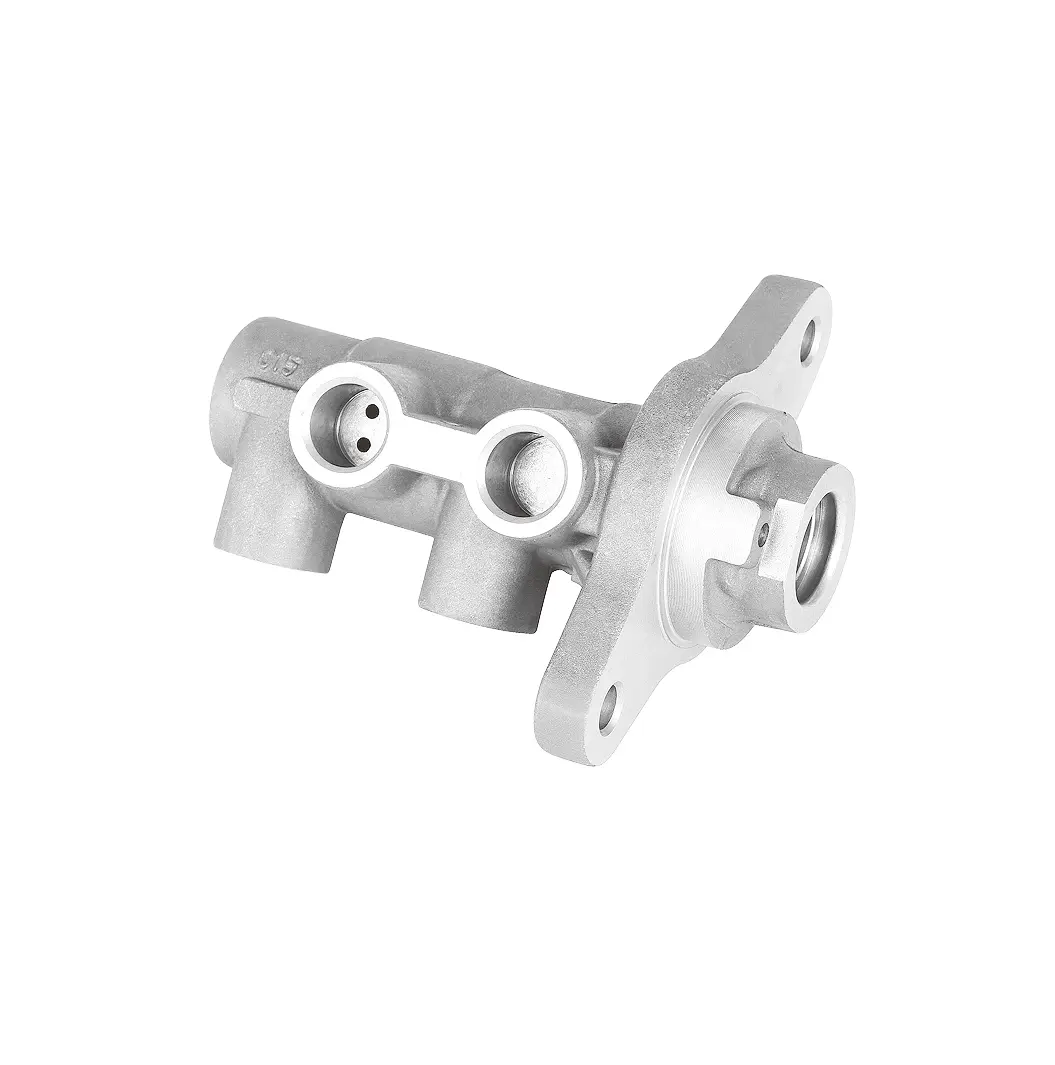

In the global aluminum alloy die-casting market, low-pressure casting technologyis widely used to produce high-quality Aluminum Alloy Castings due to its unique process advantages. However, a variety of defects may still occur during the low-pressure casting process, which not only affect the appearance quality of the casting, but also may reduce its mechanical properties and service life.

1. Porosity defects

(I) Characteristics

Porosity is a hole-like defect formed by gas inside the casting. The surface is usually smooth and mainly pear-shaped, round or oval. Porosity can be divided into the following types:

Internal pores: generally not exposed on the surface of the casting, large pores often exist in isolation, and small pores appear in groups.

Subcutaneous pores: dispersed pores located under the surface of the casting, usually found after machining or Heat Treatment.

Surface pores: a relatively smooth pore concave on the surface of the casting.

Pinholes: generally the size of a needle, precipitation pores distributed on the cross section of the casting, which are very harmful to the performance of the casting.

(II) Causes

The formation of pores is mainly related to the following factors:

Dissolved gas precipitation in molten metal: The gas contained in the metal when it is melted, when the liquid metal cools and solidifies, the gas solubility decreases and precipitates, and there is no time to remove it, forming pores.

Gases generated by chemical reactions: The mold, core, cold iron, coating, etc. contain substances that react with aluminum water to generate gas, resulting in the formation of reactive pores.

Gases in the cavity are not discharged in time: Due to unreasonable casting process design, such as poor exhaust of the mold or core, the gas in the cavity is trapped in the casting, forming invasive pores.

(III) Preventive measures

Strictly control the smelting process: Metal raw materials and recycled materials should be dry, free of rust and oil, and should be preheated before use. The smelting temperature should not be too high to reduce the amount of gas dissolved.

Reduce the gas emission of coatings and cores: Choose high-quality coatings with low gas emission, and fully dry the molds and cores after coating.

Improve exhaust conditions: According to the characteristics of the casting, choose a reasonable exhaust position and different exhaust measures, such as exhaust grooves, exhaust plates, exhaust needles, etc.

Control the filling speed: Choose a suitable filling speed, strive to fill the metal liquid smoothly, and prevent gas from being drawn in.

2. Shrinkage and shrinkage defects

(I) Characteristics

Shrinkage and shrinkage are defects caused by the failure of the molten metal to effectively compensate for the shrinkage of the casting when the metal solidifies and shrinks. The specific characteristics are as follows:

Shrinkage: There are extremely irregular holes in the casting, with rough hole walls and dendrites, which often appear in the last solidification part of the casting.

Shrinkage: There are scattered and tiny shrinkage holes on the cross section of the casting, which can sometimes be observed with the help of a magnifying glass.

Porosity: Very tiny holes appear in the slow solidification zone of the casting, distributed in and between dendrites, which reduces the density of the casting and easily causes leakage.

(II) Causes

The formation of shrinkage and shrinkage is mainly due to the failure to compensate for the volume loss caused by the volume shrinkage of the molten metal during the solidification process. In low-pressure casting, since the mold is filled from bottom to top and the gate is at the bottom, in order to ensure that the casting is adequately compensated for shrinkage, sequential solidification from top to bottom must be formed, otherwise shrinkage holes and shrinkage defects will occur.

(III) Preventive measures

Reasonably design the casting process: establish sequential solidification conditions, and take forced cooling measures for the thick parts of the casting, such as air cooling, water cooling, and cold iron.

Optimize the liquid level pressure control system: ensure that the pressure can be increased rapidly at critical moments to overcome the negative effect of gravity and compensate for shrinkage.

Control the pouring temperature and pressure: appropriately reduce the pouring temperature, increase the holding time and pressure, so as to reduce shrinkage defects.

3. Inclusion defects

(I) Characteristics

Inclusion defects are a general term for various metal and non-metal inclusions in castings, including inclusions, cold beans, infiltration beans, slag inclusions, sand holes, etc. Inclusions are usually impurity particles such as oxides, sulfides, silicates, etc., which are mechanically retained in solid metals.

(II) Causes

The main sources of inclusions include:

Oxidized slag: When adding aluminum liquid to the crucible during continuous production, the oxidized slag on the liquid surface is flushed into the riser and brought into the mold during pouring.

The coating and core material fall off: The coating on the casting tools, molds, risers, sand cores, etc. falls off, especially the sand cores are ignited and baked with fire after being painted, which will cause peeling (explosion).

(III) Preventive measures

Strictly control the filling speed: ensure that the metal liquid rises steadily without impact or splashing.

Completely remove the oxidized slag in the alloy liquid: use a filter at the riser or the inner runner of the mold, but pay attention to the applicability of the filter.

Check the coating layer: ensure that the coating layer does not fall off, and the dust, sand and debris in the cavity should be thoroughly cleaned.

4. Cold shut and insufficient pouring defects

(I) Characteristics

Cold shut: There are gaps with penetrating or non-penetrating edges on the casting, which are often separated by oxide scale in the middle and cannot be completely fused into one.

Insufficient pouring: The casting is incomplete or has an incomplete outline, with rounded and shiny corners, which often appear in the parts far away from the gate and thin walls.

(II) Causes

The formation of cold shut and insufficient pouring is mainly related to the following factors:

Low casting temperature or molten metal temperature: resulting in poor fluidity of molten metal.

Low filling pressure and slow filling speed of molten metal: It is impossible to ensure that the molten metal fully fills the mold cavity.

Poor cavity venting: The gas back pressure in the cavity is too large, which hinders the filling of molten metal.

(III) Preventive measures

Use reasonable casting temperature and molten metal pouring temperature: ensure that the molten metal has good fluidity.

Use reasonable pressurization specifications: ensure that the molten metal can fully fill the mold.

Improve the venting conditions of the mold and core: ensure that the gas in the cavity can be discharged smoothly.

5. Crack defects

(I) Characteristics

Cracks can be divided into hot cracks and cold cracks. Hot cracks occur shortly after the solid phase skeleton is formed, while cold cracks occur at lower temperatures. Cracks appear as straight or tortuous gaps and cracks on the casting, and the cross section is oxidized to black or dark gray.

(II) Causes

The formation of cracks is mainly related to the following factors:

Irrational process design: If the casting is designed with multiple adjacent bosses, cracks are likely to occur in the thin wall between the bosses.

Raw material quality issues: When the original magnesium ingot has crack defects, the cast casting will produce batch crack defects.

Improper position of the chiller: The gap between the chillers is too small, which hinders the shrinkage of the alloy and is prone to cracks.

(III) Preventive measures

Reasonable design of the process: Designing reasonable anti-crack reinforcement can effectively eliminate crack defects.

Control of raw material quality: Strengthen the control of crack defects in original magnesium ingots.

Optimize the position of the chiller: the gap between the chillers should not be less than 5 mm, and the arc surface chiller should be centripetal to prevent the rear from being pressed against each other.

6. Sand sticking defects

(I) Characteristics

Sand sticking can be divided into chemical sand sticking and mechanical sand sticking. Mechanical sand sticking is mainly used in low-pressure casting. Mechanical sand sticking is caused by the fact that the pressure of the liquid metal increases greatly during the pressure holding, forcing the liquid metal to overcome the surface tension and penetrate into the sand core or sand mold.

(II) Preventive measures

Apply a high-refractory and dense coating layer: Apply a high-refractory and dense coating layer on the surface of the sand mold or sand core to effectively overcome the sand sticking defect.

Appropriately reduce the pouring temperature and holding pressure: reduce the penetration of the liquid metal.

7. Deformation defects

(I) Characteristics

Deformation refers to the shape change of the casting caused by thermal stress, shrinkage stress, etc. during the solidification process.

(II) Causes

The formation of deformation is mainly related to the following factors:

Irrational casting structure: such as uneven thickness, no reinforcement ribs or reinforcement plates at stress concentration sites.

Irrational process design: such as unreasonable pouring system design, resulting in uneven solidification of castings.

(III) Preventive measures

Optimize casting structure: design reasonable reinforcement ribs or reinforcement plates to reduce stress concentration.

Reasonable design process: adopt reasonable pouring system and cooling system to ensure uniform solidification of castings.

8. Surface roughness defect

(I) Characteristics

Surface roughness refers to the uneven surface of the casting, with obvious unevenness.

(II) Causes

The formation of surface roughness is mainly related to the following factors:

Painting problem: poor quality of paint or insufficient drying.

Improper surface treatment of cavity: impurities on the cavity surface or not cleaned up.

(III) Preventive measures

Select high-quality paint: ensure that the paint has high refractoriness and is dense.

Clean the cavity surface: ensure that the cavity surface is clean and smooth.