+86-13516964051

+86-13516964051 Aluminum alloy low-pressure casting process

Aluminum alloy low-Pressure Casting process: unlocking the secret of improving heat dissipation efficiency

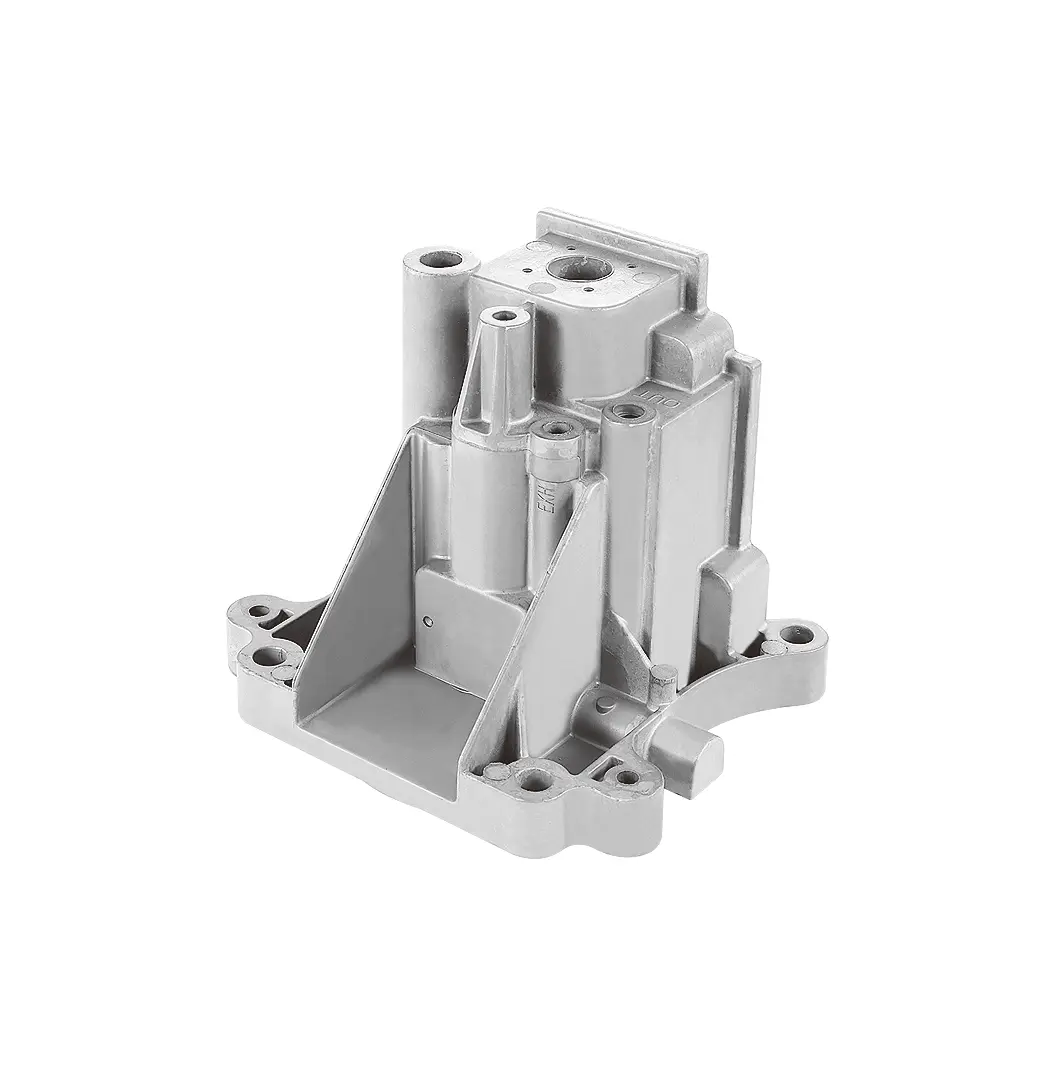

In modern industrial production, aluminum alloy low-pressure casting, as an advanced Casting Technology, is widely used in automobiles, aerospace, machinery manufacturing and other fields due to its many advantages. This article will explore the principles and characteristics of low-pressure casting process in depth, and focus on analyzing how it effectively improves heat dissipation efficiency.

I. Overview of low-pressure casting process

(I) Basic principle

Low-pressure casting is a casting method between Gravity Casting and high-pressure casting. The principle is to place the liquid aluminum alloy in a closed crucible, and press the aluminum alloy liquid from the bottom into the mold cavity placed above with compressed air or inert gas at a low pressure (generally 20-100kPa), solidify and form under pressure, and obtain the required casting.

(II) Process flow

Preparation stage: First, install the mold on the low-pressure casting machine and preheat the mold. The preheating temperature is usually between 150℃ and 300℃ to reduce the temperature difference between the mold and the aluminum alloy liquid and prevent thermal stress and cracks in the casting.

Pouring process: Pour the smelted aluminum alloy liquid into the crucible, and then introduce compressed air or inert gas into the crucible, so that the aluminum alloy liquid rises steadily along the riser under the action of gas pressure and fills into the casting cavity.

Solidification stage: The aluminum alloy liquid begins to solidify in the casting cavity. In order to ensure the quality of the casting, it is necessary to maintain a certain pressure during the solidification process to compensate for the volume shrinkage of the casting during the solidification process and prevent the occurrence of shrinkage holes, shrinkage and other defects.

Pressure relief and demolding: When the casting is completely solidified, stop introducing gas to relieve the pressure in the crucible, then open the mold and take out the casting.

(III) Process characteristics

High casting quality: During the low-pressure casting process, the aluminum alloy liquid fills and solidifies under pressure, which can effectively reduce defects such as pores and inclusions in the casting and improve the density and mechanical properties of the casting.

High dimensional accuracy: Since the molds of low-pressure casting are usually made of metal, and the pressure in the cavity during the casting process can ensure the dimensional accuracy of the castings, the dimensional accuracy of low-pressure casting castings is relatively high, generally up to CT7-CT8 level.

High production efficiency: Compared with traditional gravity casting, the production efficiency of low-pressure casting has been significantly improved. It can complete the filling and solidification process of aluminum alloy liquid in a shorter time, and it is easy to realize automated production, which further improves production efficiency.

Good safety: The pressure used in low-pressure casting is relatively low, and the casting process does not produce high pressure and high-speed metal liquid flow like high-pressure casting. Therefore, the production process is relatively safer and the operating conditions are also improved.

2. Key factors for improving heat dissipation efficiency in low-pressure casting process

(I) Mold design and heat dissipation optimization

Reasonable design of mold structure

In the design of low-pressure casting molds, full consideration should be given to heat dissipation requirements and the structural form of the mold should be optimized. For example, for castings with complex shapes, the mold is divided into multiple parts, and the back of each part is designed into a hollow shape with uniform wall thickness to enhance the heat dissipation speed of the mold, so that the casting is cooled evenly around the casting, and the problem of uneven heat dissipation caused by local overheating or slow cooling is avoided.

Reasonable design of the pouring system and overflow system allows the aluminum alloy liquid to fill the cavity smoothly and evenly, reduce turbulence and eddy current phenomena, thereby reducing the heat accumulation of the casting during the solidification process, which is conducive to heat dissipation. At the same time, the overflow system can discharge the gas in the cavity in time to prevent the gas from forming pores inside the casting, affecting the heat dissipation performance of the casting.

Use high thermal conductivity materials

Choosing mold materials with good thermal conductivity is the key to improving heat dissipation efficiency. For example, using high thermal conductivity mold materials such as 3Cr2W8V heat-resistant steel can quickly conduct the heat generated by the casting during the solidification process and speed up the heat dissipation speed.

In the key parts of the mold, such as the cavity surface in contact with the casting, metal materials with high thermal conductivity, such as beryllium copper, can be inlaid to further enhance the local heat dissipation capacity. These high thermal conductivity materials can quickly absorb the heat of the casting and conduct it to other parts of the mold or the cooling system, thereby achieving efficient heat dissipation.

Setting up a cooling system

Setting up a circulating water cooling system inside the mold, and taking away the heat generated by the mold and casting during the casting process through circulating cooling water, is one of the commonly used heat dissipation methods in low-pressure casting. The circulating water cooling system can be designed according to the shape of the mold and the heat dissipation requirements of the casting, including arranging cooling water channels around the mold cavity, core and other parts, so that the cooling water can flow evenly through all parts of the mold to achieve a good cooling effect.

In addition to the water cooling system, the air cooling system can also be used to cool the mold. For example, compressed air or inert gas is used to circulate in the air cooling channel inside the mold to take away heat and speed up the heat dissipation of the mold. The advantage of the air cooling system is that there will be no problems such as water leakage and blockage like the water cooling system, and the gas has good fluidity and can quickly take heat out of the mold.

(II) Process parameter control

Pressure control

In the low-pressure casting process, appropriately increasing the filling pressure can speed up the filling speed of the aluminum alloy liquid, so that the casting can quickly fill the mold cavity, reduce the heat dissipation time of the aluminum alloy liquid during the filling process, thereby increasing the overall temperature level of the casting, which is conducive to improving the shrinkage compensation conditions of the casting, reducing the occurrence of shrinkage holes, shrinkage and other defects, and thus improving the heat dissipation efficiency of the casting.

The control of solidification pressure is also crucial. Reasonable solidification pressure can ensure that the casting obtains sufficient shrinkage compensation during the solidification process, making the structure of the casting more dense and improving its thermal conductivity. Generally speaking, the solidification pressure should be adjusted according to factors such as the wall thickness of the casting and the shrinkage rate of the alloy to ensure that the casting can obtain good shrinkage compensation effect during the solidification process.

Temperature control

Controlling the pouring temperature of the aluminum alloy liquid is one of the important factors affecting the heat dissipation efficiency. If the pouring temperature is too high, the heat dissipation time of the casting during the solidification process will be prolonged, which may easily lead to the formation of coarse grains and a large amount of heat accumulation inside the casting, which is not conducive to heat dissipation; while if the pouring temperature is too low, the fluidity of the aluminum alloy liquid may deteriorate, and the cavity cannot be completely filled, affecting the quality and heat dissipation performance of the casting. Therefore, it is necessary to determine the appropriate pouring temperature range based on factors such as the composition of the aluminum alloy and the structure of the casting, generally between 600℃ and 750℃.

The control of mold temperature should not be ignored either. Properly increasing the mold temperature can reduce the temperature difference between the mold and the aluminum alloy liquid, so that the casting can dissipate heat more evenly during the solidification process, and avoid uneven heat dissipation caused by excessive local temperature difference. At the same time, if the mold temperature is too high, the cooling speed of the aluminum alloy liquid during the filling process will slow down, affecting the surface quality and dimensional accuracy of the casting. Therefore, it is necessary to control the mold temperature within a reasonable range, usually between 150℃ and 300℃.

3) Alloy materials and heat treatment process

Select aluminum alloy materials with high thermal conductivity

Aluminum alloys of different compositions have different thermal conductivity. In low-pressure casting, selecting aluminum alloy materials with good thermal conductivity, such as Al-Si alloys, Al-Cu alloys, etc., can effectively improve the heat dissipation efficiency of castings. The alloying elements added to these alloy materials can improve the crystal structure and organization of aluminum alloys and improve their thermal conductivity.

Optimize heat treatment process

A reasonable heat treatment process can improve the organization and performance of aluminum alloy castings, thereby improving their heat dissipation efficiency. For example, solution treatment and aging treatment of aluminum alloy castings can refine the grains, improve the strength and toughness of castings, and increase the thermal conductivity of castings. Solution treatment usually involves heating aluminum alloy castings to a high temperature so that the alloying elements are fully dissolved in the aluminum matrix to form a uniform solid solution, and then rapidly cooling to obtain a supersaturated solid solution; aging treatment involves placing the solution-treated castings at room temperature or high temperature for a period of time so that the alloying elements precipitate in the aluminum matrix to form a dispersed precipitation phase, further improving the performance of the castings.

(IV) Simulation and optimization of filling and solidification process

Filling process simulation

Using computer simulation technology to simulate and analyze the filling process of low-pressure casting can predict the flow state, temperature distribution and other conditions of aluminum alloy liquid during the filling process, so as to optimize the design of the pouring system and the selection of process parameters. Through simulation analysis, problems such as flow front stagnation, turbulence, eddy currents that may occur during the filling process can be found, and corresponding measures can be taken to improve them, such as adjusting the position and size of the gate, changing the filling speed, etc., to ensure that the aluminum alloy liquid can fill the cavity smoothly and evenly, reduce heat loss and uneven heat dissipation during the filling process.

Solidification process simulation

Simulation analysis of the solidification process of low-pressure castings can understand the temperature changes, solidification sequence, hot spot location and other information of the castings during the solidification process, and provide a basis for formulating a reasonable solidification control strategy. According to the simulation results, cooling devices can be added to the hot spot of the casting or measures can be taken to accelerate local cooling to promote sequential solidification of the casting, improve the heat dissipation efficiency of the casting, and reduce the occurrence of solidification defects.

3. Practical application cases of low-pressure casting process in heat dissipation

(I) Low-pressure casting of automobile engine cylinder block

In the low-pressure casting production of automobile engine cylinder block, the heat dissipation efficiency of the cylinder block can be effectively improved by carefully designing and optimizing the mold, using mold materials with high thermal conductivity, and setting up an efficient cooling system. At the same time, the process parameters of low-pressure casting, such as filling pressure, solidification pressure, pouring temperature and mold temperature, are strictly controlled to ensure that the temperature distribution of the aluminum alloy liquid during the filling and solidification process is uniform, so as to produce high-quality and high-heat dissipation engine cylinder block. This not only improves the operating efficiency and reliability of the engine, but also extends the service life of the engine.

(II) Low-pressure casting of new energy vehicle motor housing

The motor housing of new energy vehicles usually needs to have good heat dissipation performance to ensure the temperature stability of the motor during operation. When using the low-pressure casting process to produce the motor housing, the heat dissipation efficiency of the motor housing can be significantly improved by optimizing the mold structure and cooling system, and selecting suitable aluminum alloy materials and heat treatment processes. For example, a circulating water-cooling insert and an air-cooling pipe are set in the low-pressure casting mold of the motor housing to speed up the heat dissipation of the mold, so that the casting can be cooled quickly during the solidification process, and the thermal conductivity of the casting can be improved. In addition, by simulating and optimizing the filling and solidification process, the heat dissipation effect of the casting can be further improved to meet the strict requirements of the new energy vehicle motor on the heat dissipation performance of the housing.

(III) Low-pressure casting of aluminum alloy wheels

Aluminum alloy wheels need to bear a large heat load during the driving process of the car, so its heat dissipation performance is very important. When low-pressure casting aluminum alloy wheels, the structure and cooling system of the wheel mold are reasonably designed, high thermal conductivity alloy materials are used, and the low-pressure casting process parameters are optimized, which can effectively improve the heat dissipation efficiency of the wheel. For example, adding a cooling air box to the rim part of the wheel mold to forcefully cool the rim cavity, so that the wheel can achieve sequential solidification during the solidification process, reduce the occurrence of defects such as shrinkage and pinholes, and improve the heat dissipation performance and quality stability of the wheel.

4. Comparison of low-pressure casting process with other casting processes in terms of heat dissipation

(I) Comparison with gravity casting

Heat dissipation efficiency: Since low-pressure casting applies pressure during the filling and solidification process, the aluminum alloy liquid can fill the mold cavity more quickly, and can effectively supplement the volume shrinkage of the casting during the solidification process, making the structure of the casting denser, the thermal conductivity better, and the heat dissipation efficiency is significantly improved compared with gravity casting.

Casting quality: Low-pressure casting has higher dimensional accuracy and surface roughness, fewer defects, and further improves the heat dissipation performance and reliability of the casting.

(II) Comparison with high-pressure casting

Heat dissipation efficiency: Although high-pressure casting has higher production efficiency, due to its extremely fast filling speed of the metal liquid during the casting process, turbulence and eddy currents are easily generated, resulting in a large number of defects such as pores and inclusions inside the casting, affecting the thermal conductivity of the casting. The filling speed of low-pressure casting is relatively stable, which can reduce the defects inside the casting, thereby improving the heat dissipation efficiency of the casting to a certain extent.

Casting quality: Low-pressure castings are generally superior to high-pressure castings in terms of mechanical properties and corrosion resistance, which also provides a better basis for their application in heat dissipation.

V. Future development direction and challenges of low-pressure casting process

(I) Development direction

Intelligence and automation: With the continuous development of industrial automation technology, low-pressure casting process will develop in the direction of intelligence and automation. By introducing technologies such as robots, automated control systems and sensors, the low-pressure casting process can be automatically controlled and monitored to improve production efficiency and the stability of casting quality. At the same time, the low-pressure casting process parameters are optimized using big data analysis and artificial intelligence algorithms to further improve the heat dissipation efficiency and performance of castings.

Research and development of new materials and new processes: In order to meet the higher requirements of the industrial field for the heat dissipation and mechanical properties of aluminum alloy castings, new aluminum alloy materials and low-pressure casting processes will be continuously developed in the future. For example, aluminum alloy materials with higher thermal conductivity and strength will be developed, and new casting process technologies such as vacuum low-pressure casting and semi-solid low-pressure casting will be adopted to further improve the heat dissipation efficiency and quality of castings.

In-depth implementation of the green casting concept: In the context of increasingly stringent environmental protection requirements, the low-pressure casting process will pay more attention to the implementation of the green casting concept. The sustainable development of low-pressure casting can be achieved by adopting energy-saving casting equipment, optimizing casting process parameters to reduce energy consumption, and reducing the emission of waste slag and exhaust gas.

(II) Challenges

Breakthrough of technical bottlenecks: Although the low-pressure casting process has achieved certain results in improving heat dissipation efficiency, it still faces some technical bottlenecks, such as how to further improve the thermal conductivity of castings and reduce the production cost of castings. Breaking through these technical bottlenecks requires increasing R&D investment, strengthening industry-university-research cooperation, and jointly overcoming technical difficulties.

Market competition pressure: With the increasingly fierce competition in the casting industry, low-pressure casting companies are facing competitive pressure from domestic and foreign peers. How to improve the core competitiveness of enterprises and continuously expand market share is an important issue that low-pressure casting companies need to solve in their future development.

Talent shortage: The low-pressure casting process involves knowledge and technology in multiple disciplines, and has high requirements for professional talents. However, there is a relative shortage of talents in the casting industry, especially high-quality talents who understand casting technology and have innovation capabilities. This has limited the development and technological progress of low-pressure casting technology to a certain extent.