+86-13516964051

+86-13516964051 Aluminum alloy high pressure casting

1. Overview of aluminum alloy high pressure casting

1.1 Definition and principle

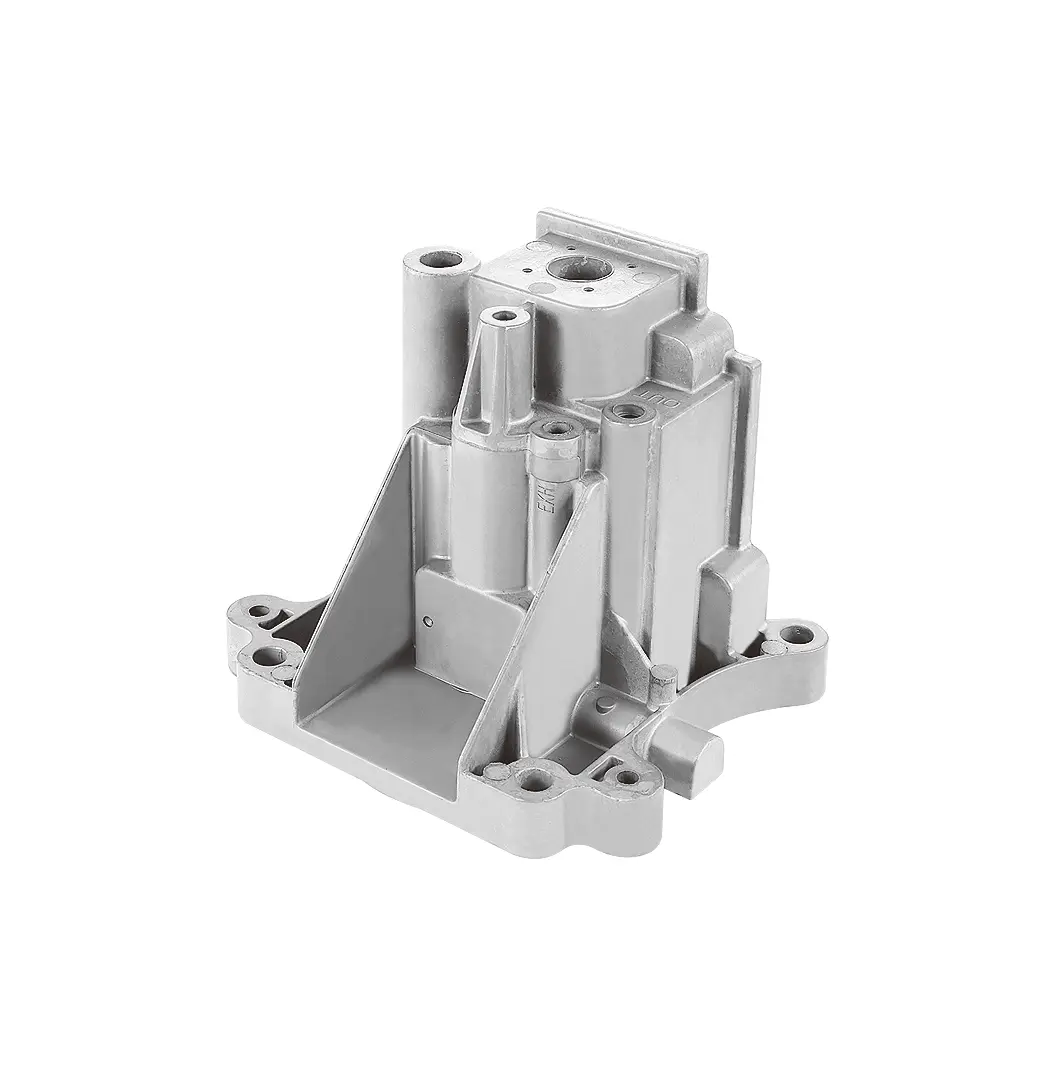

Aluminum alloy high pressure casting is an advanced metal forming process. Liquid aluminum alloy is quickly injected into the mold cavity under high pressure and solidified under high pressure to obtain Aluminum Alloy Castings with excellent performance and complex shapes. The core of this process is to use the characteristics of high pressure and rapid filling to make the aluminum alloy solidify in a short time, thereby achieving high-precision and high-strength casting production.

High pressure characteristics: In the aluminum alloy high pressure Casting Process, the pressure range usually used is 80-200 MPa. This high pressure environment can effectively reduce the pores and shrinkage defects inside the casting and improve the density and strength of the casting. For example, compared with traditional low-pressure casting, the tensile strength of aluminum alloy castings produced by high pressure casting can be increased by 20%-30%, and the elongation can be increased by 10%-20%.

Fast filling: Liquid aluminum alloy enters the mold cavity at a very high speed (usually 10-100 m/s) under high pressure, quickly filling every corner of the cavity to ensure the shape accuracy and dimensional stability of the casting. Fast filling can also reduce the oxidation and cold shut of the molten metal in the cavity, further improving the quality of the casting.

Solidification process: Under high pressure, aluminum alloy castings solidify faster and have smaller grain sizes, which gives the castings higher mechanical properties and better corrosion resistance. Studies have shown that the grain size of high-pressure cast aluminum alloy castings is usually between 10-50 microns, which is much smaller than the grain size of castings produced by traditional casting processes (generally 100-200 microns).

This process is widely used in fields such as automobiles, aerospace, and electronics that have high requirements for casting quality and precision. For example, in automobile manufacturing, aluminum alloy high-pressure casting is used to produce key components such as engine blocks and transmission housings, which not only reduces the weight of components, but also improves their mechanical properties and reliability.

2. Process Flow

2.1 Metal Melting

Metal melting for aluminum alloy high pressure casting is the starting point of the whole process and has a decisive influence on the quality of the final casting.

Melting Equipment: Crucible furnace or induction furnace is usually used for aluminum alloy melting. Crucible furnace is suitable for small batch production, and its melting temperature control accuracy is relatively low, but the equipment cost is low; induction furnace has the advantages of fast melting speed, precise temperature control, uniform alloy composition, etc., which is suitable for large-scale production. According to statistics, the composition uniformity of aluminum alloy melted by induction furnace can be improved by 30%, and the melting efficiency can be improved by 25%.

Raw Material Selection: It is very important to select high-quality aluminum alloy raw materials. The purity of raw materials directly affects the performance of castings. For example, aluminum ingots with higher purity produce fewer impurities during the melting process, which can reduce the defects inside the casting. Generally, the purity of aluminum ingots is required to be not less than 99.5%, and the impurity content is controlled within 0.5%. In addition, adding an appropriate amount of alloying elements (such as silicon, copper, magnesium, etc.) can adjust the properties of aluminum alloys, such as strength and toughness. Taking Al-Si alloy as an example, when the silicon content is 10%-13%, the alloy has good casting performance and wear resistance.

Melting process control: Temperature and time need to be strictly controlled during the melting process. The melting temperature of aluminum alloy is generally between 700-750℃. Too high temperature will cause severe oxidation of aluminum alloy and produce a large number of aluminum oxide inclusions; too low temperature will make the fluidity of aluminum alloy worse, affecting the subsequent filling process. The melting time is generally controlled at 1-2 hours. Too long melting time will change the alloy composition and affect the performance of the casting. By accurately controlling the melting parameters, the oxidation loss rate of aluminum alloy can be effectively reduced to less than 1%, and the qualified rate of castings can be improved.

2.2 Mold preparation and spraying

The mold is a key component of aluminum alloy high-pressure casting. Its preparation and spraying quality directly affect the surface quality and dimensional accuracy of the casting.

Mold material selection: The mold material needs to have high strength, high hardness, good thermal conductivity and heat resistance. Commonly used mold materials are hot working die steel (such as H13 steel) and cemented carbide. H13 steel has good comprehensive properties, hardness can reach 50-55 HRC, high thermal conductivity, and can withstand high temperature and high pressure impact during high-pressure casting. Carbide molds have higher hardness and wear resistance, but the cost is higher. They are mainly used to produce castings with complex shapes and high precision requirements. According to statistics, the surface roughness of castings produced using H13 steel molds can reach Ra0.8-1.6μm, and the dimensional accuracy can be controlled within ±0.1mm.

Mold design and manufacturing: Mold design needs to consider factors such as the shape, size, and wall thickness of the casting to ensure that the molten metal can be smoothly filled and solidified. The surface roughness of the mold cavity is required to be high, generally Ra0.4-0.8μm, to reduce the sticking phenomenon on the surface of the casting. The design of the cooling system of the mold is also crucial. By reasonably arranging the cooling water channel, the solidification speed of the casting can be effectively controlled and the quality of the casting can be improved. For example, in the engine cylinder mold, the layout of the cooling water channel can shorten the solidification time of the casting by 20%-30% and reduce the thermal cracks inside the casting.

Mold spraying: Spraying a layer of release agent on the mold surface is an essential step in aluminum alloy high-pressure casting. The role of the release agent is to prevent the casting from sticking to the mold and reduce the defects on the surface of the casting. Commonly used release agents are water-based release agents and oil-based release agents. Water-based release agents have the advantages of environmental protection and low cost, but they evaporate quickly and need to be sprayed frequently; oil-based release agents have good lubricity and adhesion, and can maintain the demolding effect on the mold surface for a long time. The surface temperature of the mold after spraying is generally controlled at 200-250℃ to ensure that the release agent can be evenly distributed and form an effective isolation layer. Through a reasonable spraying process, the demolding success rate of the casting can be increased to more than 98%.

2.3 Metal filling and solidification

Metal filling and solidification are the core links of aluminum alloy high-pressure casting, which determine the final quality and performance of the casting.

Filling process: Under high pressure, the liquid aluminum alloy enters the mold cavity at an extremely high speed (10-100 m/s). The control of the filling speed is crucial. Too fast a filling speed may cause the molten metal to splash, produce pores and oxide inclusions; too slow a filling speed will cause the molten metal to cool too quickly in the cavity and fail to completely fill the cavity. Multi-stage filling speed control technology is usually used. A lower speed (10-20 m/s) is used in the initial stage to reduce the splashing of the molten metal; the speed is gradually increased (40-60 m/s) in the middle stage to ensure that the molten metal can quickly fill the cavity; the speed is reduced in the final stage (20-30 m/s) so that the molten metal can smoothly fill every corner of the cavity. Through this multi-stage filling speed control, the porosity of the casting can be reduced to less than 2%.

Solidification process: Aluminum alloy solidifies under high pressure in the mold cavity, with a faster solidification speed and a smaller grain size (10-50 microns). High-pressure solidification can effectively reduce shrinkage and shrinkage defects inside the casting and improve the density and strength of the casting. For example, the tensile strength of aluminum alloy castings produced by high-pressure casting can reach 250-300 MPa, and the elongation is 5%-10%, which is much higher than that of castings produced by traditional casting processes. During the solidification process, the cooling system of the mold plays an important role. By reasonably controlling the cooling rate, the microstructure and performance of the casting can be further optimized. For example, the use of segmented cooling technology, first quickly cooling the surface of the casting and then slowly cooling the inside, can make the grain size of the casting evenly distributed and improve the overall performance of the casting.

Defect control: During the filling and solidification process, the defects inside the casting need to be strictly controlled. Common defects include pores, shrinkage, cold shut, etc. Porosity is mainly caused by the molten metal entraining air during the filling process or poor mold exhaust. By optimizing the mold design and increasing the exhaust channel, the generation of pores can be effectively reduced. Shrinkage and shrinkage holes are caused by the volume shrinkage of the molten metal during the solidification process. The use of reasonable gating system design and shrinkage feeding technology, such as setting risers or using sequential solidification technology, can effectively reduce shrinkage and shrinkage defects. Cold shut is caused by the interruption or discontinuous flow of molten metal during the filling process. Cold shut can be reduced by increasing the filling speed and optimizing the mold temperature distribution. By comprehensively controlling these defects, the qualified rate of castings can be increased to more than 95%.

3. Technical characteristics

3.1 Advantages

Aluminum alloy high-pressure casting technology has many significant advantages, making it popular in modern manufacturing.

High production efficiency: Aluminum alloy high-pressure casting can achieve rapid filling and solidification, and has a short production cycle. From molten metal filling to casting solidification, the entire process takes only a few seconds to tens of seconds. For example, when producing small aluminum alloy automotive parts, the number of castings that can be produced per hour can reach 200-300 pieces. Compared with the traditional sand casting process, the production efficiency is increased by 5-10 times, which greatly meets the large-scale production needs of the automotive and other industries.

Good surface quality: The surface of the castings produced by this process is smooth and flat, with low surface roughness. Because the molten metal fills the mold quickly under high pressure, it can well replicate the shape and surface details of the mold cavity. Generally speaking, the surface roughness of castings can reach Ra0.4-1.6μm, which can meet the appearance requirements of most products without additional surface treatment. In the manufacture of some electronic product housings with high surface quality requirements, high-pressure castings can be directly used for subsequent assembly and use, reducing processing procedures and costs.

High dimensional accuracy: Aluminum alloy high-pressure casting can accurately control the dimensional accuracy of castings. The high-precision manufacturing of molds and the rapid filling of molten metal during high-pressure filling make the dimensional deviation of castings extremely small. The dimensional accuracy can be controlled within ±0.1mm, and even in the manufacture of some high-precision aerospace parts, the accuracy can reach a higher level. This reduces the workload of subsequent machining, improves production efficiency and material utilization, and reduces production costs.

Complex shape casting manufacturing capability: This process is capable of producing complex-shaped, thin-walled castings. Since the molten metal can quickly fill every corner of the mold cavity under high pressure, even very complex structures, such as the intake duct and cooling water channel of the automobile engine block, can be accurately formed. This provides greater freedom for product design, allowing designers to design lighter, high-performance products to meet the needs of modern manufacturing for complex parts.

High strength and good mechanical properties: During the high-pressure casting process, the molten metal solidifies under high pressure, the grain size is small, and the casting has few internal defects, so it has high strength and good mechanical properties. For example, the tensile strength of high-pressure cast aluminum alloy castings can reach 250-300 MPa, and the elongation is 5%-10%. Compared with castings produced by traditional casting processes, the strength and toughness are significantly improved. This enables the castings to withstand greater loads and stresses, meeting the requirements of high strength and reliability of parts in the automotive, aerospace and other fields.

3.2 Disadvantages

Although aluminum alloy high-pressure casting has many advantages, there are also some inevitable disadvantages.

Internal pore problem: During the filling process of the molten metal, air is easily drawn in, resulting in pores inside the casting. Although the generation of pores can be reduced by optimizing the mold design and controlling the filling speed, it is still difficult to completely avoid pores. The presence of pores will reduce the strength and corrosion resistance of the casting, affecting the performance and service life of the casting. For example, in some castings subjected to high pressure or high stress, pores may become the origin of cracks, causing premature failure of the casting.

Heat treatment limitations: There are certain limitations when heat treatment is performed on aluminum alloy high pressure casting castings. Due to the possibility of residual stress inside the casting, the casting may be deformed or cracked during the heat treatment process. In addition, the alloy composition and organizational structure of some high pressure casting aluminum alloys may change during the heat treatment process, affecting the performance of the casting. This makes it necessary to carefully select the heat treatment process and parameters when heat treatment is required to further improve the performance of the casting, increasing the complexity and cost of the production process.

High mold cost: Aluminum alloy high pressure casting requires the use of high strength, high hardness, and good heat resistance mold materials, such as H13 steel or cemented carbide. The mold manufacturing precision requirements are high and the processing difficulty is high, resulting in high mold costs. The cost of a complex set of automobile engine block high pressure casting molds can reach hundreds of thousands or even millions of yuan. In addition, the service life of the mold is also limited. After producing a certain number of castings, it needs to be repaired or replaced, which increases the production cost and production cycle.

Large equipment investment: Aluminum alloy high-pressure casting requires the use of professional high-pressure casting equipment, including high-pressure injection machines, mold heating and cooling systems, and automatic control systems. These equipment are expensive and have high investment costs. For example, the price of a medium-sized high-pressure injection machine can reach millions of yuan, which puts high demands on the financial strength of the enterprise and limits the adoption of some small enterprises.

High requirements for raw materials and processes: Aluminum alloy high-pressure casting has strict requirements on the purity and quality of raw materials. Excessive impurity content in raw materials will affect the quality and performance of castings. At the same time, the entire process needs to be precisely controlled, including parameters such as melting temperature, filling speed, mold temperature, cooling speed, etc. Problems in any link may lead to casting defects. This increases the complexity of the production process and the requirements for the technical level of operators, and poses a high challenge to the production management level of the enterprise.

4. Influencing factors

4.1 Process parameters (pressure, speed, temperature, etc.)

The quality and performance of aluminum alloy high pressure casting are affected by a variety of process parameters, among which pressure, speed and temperature are key factors.

Pressure: Pressure is one of the core parameters of aluminum alloy high pressure casting. Usually, the casting pressure ranges from 80-200 MPa. Higher pressure can effectively reduce the pores and shrinkage defects inside the casting and improve the density and strength of the casting. For example, when the pressure increases from 80 MPa to 150 MPa, the tensile strength of the casting can be increased by 15%-20%, and the porosity can be reduced by about 30%. In addition, the high pressure environment can also promote the rapid filling of the molten metal to ensure the shape accuracy and dimensional stability of the casting.

Speed: Filling speed is an important factor affecting the quality of the casting. Liquid aluminum alloy enters the mold cavity at a very high speed (10-100 m/s) under high pressure. The control of the filling speed is crucial. Too fast a filling speed may cause the molten metal to splash, produce pores and oxide inclusions; too slow a filling speed will cause the molten metal to cool too quickly in the cavity and fail to completely fill the cavity. Multi-stage filling speed control technology is usually adopted, with a lower speed (10-20 m/s) in the initial stage, a gradually increased speed (40-60 m/s) in the middle stage, and a reduced speed (20-30 m/s) in the final stage. Through this multi-stage filling speed control, the porosity of the casting can be reduced to less than 2%.

Temperature: Temperature control runs through the entire aluminum alloy high-pressure casting process. The melting temperature is generally between 700-750℃. Too high a temperature will cause severe oxidation of the aluminum alloy and produce a large number of aluminum oxide inclusions; too low a temperature will deteriorate the fluidity of the aluminum alloy and affect the subsequent filling process. The mold temperature also needs to be strictly controlled, usually between 200-250℃, to ensure that the release agent can be evenly distributed and form an effective isolation layer. By properly controlling the temperature, the oxidation loss rate of aluminum alloy can be effectively reduced to less than 1%, and the qualified rate of castings can be improved.

4.2 Mold design and materials

The mold is a key component of aluminum alloy high-pressure casting. Its design and material selection have a decisive influence on the quality and production efficiency of castings.

Mold design: Mold design needs to comprehensively consider factors such as the shape, size, and wall thickness of the casting to ensure that the molten metal can be smoothly filled and solidified. The surface roughness of the mold cavity is required to be high, generally Ra0.4-0.8μm, to reduce the sticking phenomenon on the surface of the casting. The design of the mold cooling system is also very important. By reasonably arranging the cooling water channel, the solidification speed of the casting can be effectively controlled and the quality of the casting can be improved. For example, in the engine cylinder mold, the layout of the cooling water channel can shorten the solidification time of the casting by 20%-30% and reduce the thermal cracks inside the casting.

Mold material: The mold material needs to have high strength, high hardness, good thermal conductivity and heat resistance. Commonly used mold materials are hot working die steel (such as H13 steel) and cemented carbide. H13 steel has good comprehensive properties, hardness can reach 50-55 HRC, high thermal conductivity, and can withstand high temperature and high pressure impact during high-pressure casting. Carbide molds have higher hardness and wear resistance, but the cost is higher. They are mainly used to produce castings with complex shapes and high precision requirements. According to statistics, the surface roughness of castings produced using H13 steel molds can reach Ra0.8-1.6μm, and the dimensional accuracy can be controlled within ±0.1mm.

5. Application areas

5.1 Automobile industry (engine parts, wheels, etc.)

Aluminum alloy high-pressure casting has a wide range of applications in the automotive industry, especially in the production of engine parts and wheels, where its advantages are significant.

Engine parts: Key parts such as engine cylinders and transmission housings are important application objects of aluminum alloy high-pressure casting. These parts need to withstand high pressure, high temperature and high mechanical load, and have extremely high requirements for the strength, heat resistance and dimensional accuracy of the material. Aluminum alloy high pressure casting can produce castings with uniform wall thickness and few internal defects. Its tensile strength can reach 250-300 MPa and its elongation is 5%-10%, which can meet the strict requirements of engine components. For example, the engine block produced by an automobile manufacturer using aluminum alloy high pressure casting has a 20% weight reduction and a 30% increase in strength, which significantly improves the performance and fuel efficiency of the engine.

Wheel hub: Aluminum alloy wheel hub is an important part of automobile lightweighting. High pressure casting technology can produce wheels with complex shapes and precise dimensions. Its surface quality is high and it can be used directly without additional processing. In addition, the corrosion resistance and wear resistance of high pressure cast aluminum alloy wheels are also better than those produced by traditional casting processes. According to statistics, the service life of wheels produced by aluminum alloy high pressure casting can be extended by 30%-50%, while reducing the rolling resistance of the vehicle and improving fuel economy.

5.2 Electronic products (housings, parts, etc.)

In the manufacture of electronic products, aluminum alloy high pressure casting also plays an important role, especially in the production of housings and parts.

Shell: The shell of electronic products needs to have good appearance quality, dimensional accuracy and electromagnetic shielding performance. Aluminum alloy high-pressure casting can produce smooth and precise shells with a surface roughness of Ra0.4-1.6μm, which can meet the appearance requirements without additional surface treatment. In addition, the electromagnetic shielding performance of high-pressure cast aluminum alloy is better than that of traditional materials, which can effectively protect electronic equipment from electromagnetic interference. For example, a smartphone manufacturer uses aluminum alloy high-pressure casting to produce a mobile phone shell with a thickness of only 1.5 mm, which reduces the weight by 15%, and improves the product's anti-fall performance and electromagnetic shielding effect.

Parts: The internal parts of electronic products have extremely high requirements for precision and reliability. Aluminum alloy high-pressure casting can produce complex-shaped and thin-walled parts with dimensional accuracy within ±0.1mm, and even in some high-precision applications, the accuracy can reach a higher level. These parts can not only meet the functional requirements of electronic products, but also realize the lightweight and miniaturization of products. For example, in laptops, the weight of radiators, brackets and other parts produced by aluminum alloy high-pressure casting is reduced by 20%, and the heat dissipation performance is improved by 15%, which significantly improves the performance and user experience of the product.

6. Development Trends

6.1 Technological Innovation (such as Vacuum Die Casting)

Aluminum alloy high-pressure casting technology is constantly developing towards higher precision, higher quality and more environmentally friendly directions, and technological innovation is the core driving force for its development.

Vacuum die-casting technology: Vacuum die-casting is one of the important development directions of aluminum alloy high-pressure casting. This technology reduces the gas content in the molten metal by vacuuming during the filling process, thereby effectively reducing the porosity inside the casting. Studies have shown that vacuum die-casting can reduce the porosity of castings to less than 1%, increase the tensile strength by 10%-15%, and increase the elongation by 5%-8%. For example, the engine cylinder block produced by a certain automotive parts manufacturer using vacuum die-casting technology has significantly improved its strength and reliability, meeting the needs of high-performance automotive engines.

Semi-solid die-casting technology: Semi-solid die-casting is an emerging aluminum alloy forming process. Its principle is to heat the aluminum alloy to a semi-solid state and then fill the mold under high pressure. Compared with traditional high-pressure casting, semi-solid die-casting can reduce the oxidation and inclusions of the molten metal and improve the surface quality and internal quality of the casting. The castings produced by semi-solid die casting have smaller grain size, better mechanical properties and higher dimensional accuracy. At present, semi-solid die casting technology has been applied in aerospace, automobile and other fields, and its market share is gradually increasing.

Intelligent and automated technology: With the advancement of Industry 4.0, the level of intelligence and automation of aluminum alloy high-pressure casting continues to improve. By introducing advanced sensor technology, automated control systems and big data analysis, real-time monitoring and precise control of the casting process can be achieved. For example, the intelligent control system can automatically adjust the casting pressure and mold temperature according to parameters such as the temperature of the molten metal and the filling speed to ensure the stability of the casting quality. The application of intelligent technology not only improves production efficiency, but also reduces production costs and defective rates.

6.2 Market demand and environmental protection requirements

The development of aluminum alloy high-pressure casting is driven by both market demand and environmental protection requirements. Enterprises need to actively respond to environmental challenges while meeting market demand.

Market demand: With the rapid development of industries such as automobiles, aerospace, and electronics, the demand for aluminum alloy high-pressure castings continues to grow. The automotive industry is particularly in urgent need of lightweight and high-performance parts, and the application of aluminum alloy high-pressure castings in automotive engine parts, wheels, body structural parts and other fields is constantly expanding. According to statistics, the market size of aluminum alloy high-pressure castings for automobiles will grow at an average annual rate of 10% in the next five years. In addition, the trend of miniaturization and high performance of electronic products has also promoted the application of aluminum alloy high-pressure casting technology in this field, and the market demand prospects are broad.

Environmental protection requirements: Under the background of increasingly stringent environmental protection policies, aluminum alloy high-pressure casting enterprises face higher environmental protection requirements. On the one hand, enterprises need to reduce energy consumption and pollutant emissions in the production process. For example, energy-saving smelting equipment and efficient cooling systems can be used to reduce energy consumption; by optimizing process parameters and using environmentally friendly release agents, waste gas and waste slag emissions can be reduced. On the other hand, enterprises also need to strengthen the recycling of waste aluminum, improve resource utilization, and reduce the impact on the environment. At present, some large aluminum alloy high-pressure casting enterprises have established a complete waste aluminum recycling system, and the recycling rate of waste aluminum can reach more than 80%, which not only saves resources but also reduces environmental pollution.

7. Summary

As an advanced metal forming process, aluminum alloy high-pressure casting plays an extremely important role in modern manufacturing. Through in-depth research on its definition, process flow, technical characteristics, influencing factors, application fields and development trends, we can fully understand the advantages and challenges of this process.

Aluminum alloy high pressure casting is widely used in automobiles, aerospace, electronics and other fields with high requirements for casting quality and precision due to its significant advantages such as high production efficiency, good surface quality, high dimensional accuracy, complex shape casting manufacturing ability, high strength and good mechanical properties. However, this process also has some disadvantages, such as internal pore problems, heat treatment restrictions, high mold cost, large equipment investment, and high requirements for raw materials and processes, which to a certain extent limit its wider application.

Process parameters (such as pressure, speed, temperature, etc.) and mold design and materials are key factors affecting the quality and performance of aluminum alloy high pressure casting. By accurately controlling these parameters and optimizing mold design, the quality and production efficiency of castings can be effectively improved. In addition, technological innovation (such as vacuum die casting, semi-solid die casting, intelligent and automated technology, etc.) and the promotion of market demand and environmental protection requirements have also provided new opportunities and challenges for the development of aluminum alloy high pressure casting.

In the future, aluminum alloy high pressure casting technology will develop towards higher precision, higher quality, more environmentally friendly and more intelligent. Enterprises need to actively respond to environmental challenges while meeting market demand, continuously optimize process parameters, improve technological innovation capabilities, and reduce production costs to achieve sustainable development.