+86-13516964051

+86-13516964051 Aluminum alloy die-castings after surface treatment: the golden key to open multi-industry applications

Aluminum alloy die-castings after surface treatment: the golden key to open multi-industry applications

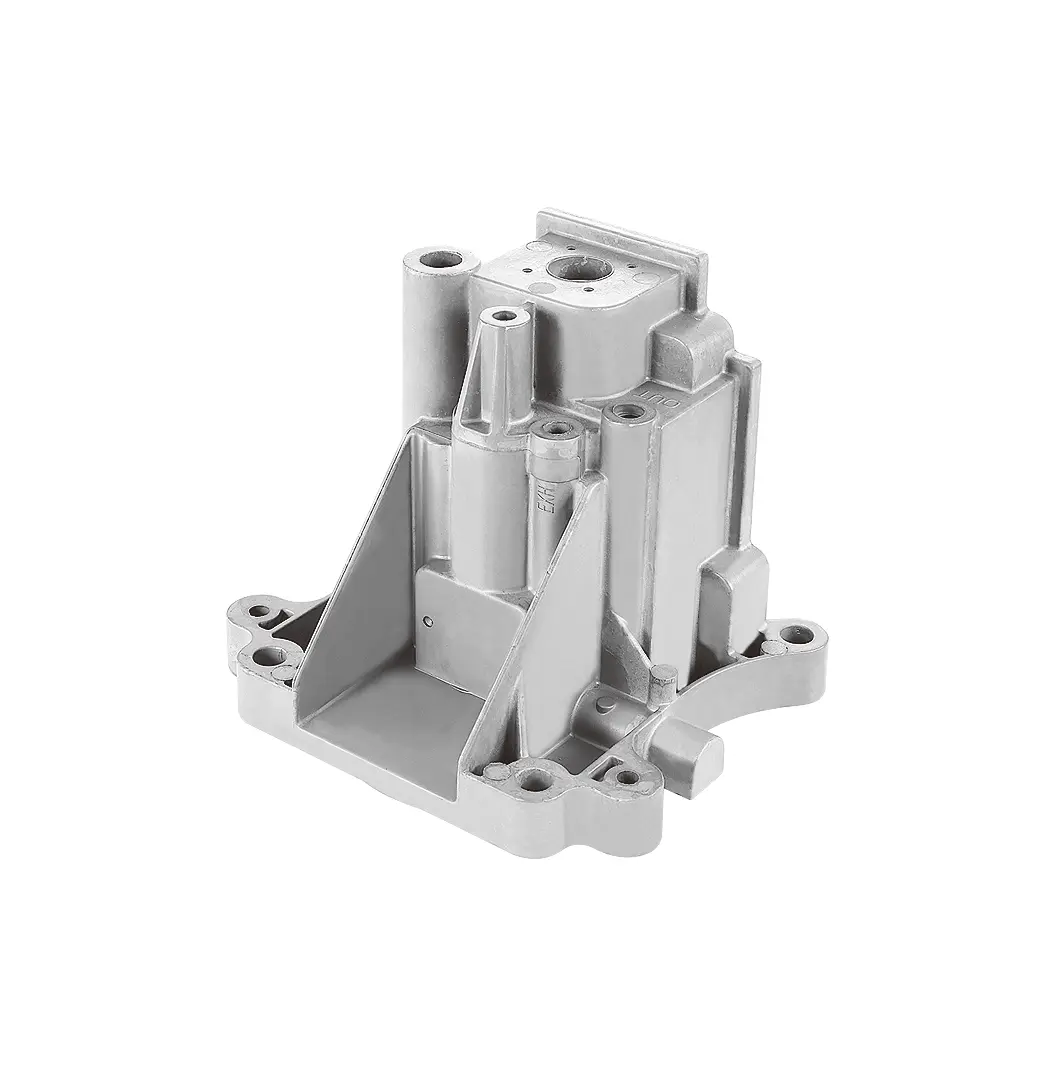

In the vast map of the manufacturing industry, aluminum alloy die-castings are quietly penetrating into various industries with their unique advantages and becoming an indispensable key component. The exquisite application of surface treatment technology has opened up a vast world of multi-industry applications for it. Today, let us explore the secret of aluminum alloy die-castings after surface treatment and shine in different fields.

1. Automobile manufacturing: a broad stage for aluminum alloy die-castings

As the crown jewel of modern industry, the automobile industry has almost stringent requirements on the quality and performance of parts. Aluminum alloy die-castings have shown their prowess in the field of automobile manufacturing with their excellent mechanical properties and lightweight characteristics. The blessing of surface treatment technology has further enhanced its application value in this field.

In the automobile engine system, the cylinder block of aluminum alloy die-casting is precisely anodized to form a dense oxide film. This film not only enhances the wear resistance and corrosion resistance of the cylinder block, but also significantly improves its thermal stability. When the engine is running at high speed, the cylinder body can withstand the harsh working conditions of high temperature and high pressure to ensure the reliable operation of the engine. Data shows that the service life of the aluminum alloy cylinder body after anodizing can be extended by more than 30%.

In terms of automobile body structural parts, aluminum alloy die-castings also shine. Through advanced electroplating technology, a solid metal coating is formed on the surface of aluminum alloy body parts. This coating not only gives the body parts a high-gloss decorative effect, making their appearance more fashionable and high-end, but also greatly enhances the impact resistance and corrosion resistance of the parts. During the life cycle of the car, even in harsh natural environments, such as high salt fog environments in coastal areas or cold and snowy conditions in northern areas, the electroplated aluminum alloy body parts can still maintain good appearance and performance.

In addition, aluminum alloy die-castings are also increasingly used in automobile chassis systems, braking systems, etc. For example, the aluminum alloy die-cast brake calipers have a smoother and flatter surface after deburring and sandblasting, which not only improves the assembly accuracy of the brake calipers, but also reduces the resistance and noise during braking, and improves driving safety and comfort.

2. Aerospace: The high-end journey of Aluminum Alloy Die Castings

In the field of aerospace, the performance requirements for materials have reached the extreme. Parts must not only have the characteristics of high strength and light weight, but also maintain excellent stability and reliability in extreme environments. Aluminum alloy die castings after surface treatment have become key materials in aerospace manufacturing due to their excellent performance.

In the fuselage structure of aircraft, a large number of aluminum alloy die castings with special surface treatment are used. For example, after anodizing treatment, key components such as the wing spars and ribs of the aircraft form a uniform and dense oxide film on their surface. This film not only improves the corrosion resistance and fatigue resistance of the components, but also enhances its connection strength with surrounding materials. During the long-term flight of the aircraft, these components can withstand huge aerodynamic loads and environmental changes to ensure flight safety.

In the field of aero engines, the application of aluminum alloy die castings is also crucial. Some high-performance aluminum alloy die castings, such as the compressor blades of the engine, are treated with special chemical plating to form a coating with excellent wear resistance and high temperature resistance on the surface. Under the high-speed rotation and high-temperature environment of the engine, these coatings can effectively prevent the wear and oxidation of the blade surface, extend the service life of the blade, and ensure the efficient operation of the engine.

3. Electronics and electrical appliances: the smart choice of aluminum alloy die-castings

With the rapid development of science and technology, the requirements for the precision and performance of parts in the electronic and electrical industry are constantly improving. Aluminum alloy die-castings have become a popular material in the manufacture of electronic and electrical appliances due to their good electrical conductivity, thermal conductivity and machinability. The application of surface treatment technology provides more possibilities for aluminum alloy die-castings in this field.

In the field of consumer electronics, such as smart phones and tablets, the shell of aluminum alloy die-casting has not only a stylish and exquisite appearance after high-gloss electroplating treatment, but also has good electromagnetic shielding and heat dissipation performance. This enables electronic products to maintain a stable working state at high speeds, while bringing users a pleasant experience.

In the field of communication equipment, aluminum alloy die-castings are widely used in key components such as filters and shielding covers of 5G base stations. These components are treated with precision powder spraying to form a uniform and firm coating on the surface, which can effectively prevent signal interference and improve the stability and reliability of communication equipment. Ensure efficient transmission of 5G signals in a complex electromagnetic environment.

4. Architectural decoration: the perfect combination of beauty and practicality of aluminum alloy die-castings

In the field of architectural decoration, people have a high pursuit of the beauty and durability of materials. Aluminum alloy die-castings after surface treatment have become an ideal choice for architectural decoration with their rich colors, unique texture and excellent weather resistance.

Aluminum alloy doors, windows and curtain walls, as common elements of modern architecture, are usually treated with powder spraying. This treatment method can form a layer of brightly colored and weather-resistant coating on the surface of aluminum alloy. Powder spray coating has excellent UV resistance and color stability, and can maintain the beautiful appearance of doors, windows and curtain walls under long-term wind, sun and rain. At the same time, the powder spray coating also has good thermal insulation performance, effectively reducing the energy consumption of buildings and contributing to energy conservation and emission reduction.

In interior decoration, aluminum alloy die-casting furniture accessories, decorative lines and other products are also popular. Through colorful spraying technology, these products can achieve a variety of decorative effects such as metal texture, wood grain, stone grain, etc., to meet the personalized needs of consumers. In the decoration of public buildings such as hotels and shopping malls, surface-treated aluminum alloy die-castings can not only enhance the beauty of the space, but also withstand the long-term use test of high traffic.

5. Medical devices: the health guardian of aluminum alloy die-castings

The medical device industry has extremely strict requirements on the safety, reliability and biocompatibility of materials. The application of aluminum alloy die-castings in this field benefits from its good biocompatibility and easy cleaning and disinfection. The introduction of surface treatment technology makes its advantages in the field of medical devices more prominent.

In the manufacture of medical device shells, aluminum alloy die-castings undergo special sandblasting treatment, and the surface becomes uniform and delicate without any sharp edges and burrs. This not only improves the aesthetics and easy cleanability of medical equipment, but also effectively prevents the growth and spread of bacteria and viruses on the surface of the equipment. In medical institutions such as hospitals, these surface-treated aluminum alloy medical equipment shells can provide patients and medical staff with a safer and more hygienic medical environment.

In the manufacturing of medical equipment parts, such as handles and brackets of surgical instruments, aluminum alloy die-castings are treated with precision electroplating to form a smooth and wear-resistant metal coating on the surface. This coating not only improves the service life of the parts, but also ensures the accuracy and reliability of surgical instruments during use. In some minimally invasive surgical instruments, aluminum alloy parts after electroplating can also produce good biocompatibility with human tissue, reduce surgical risks, and promote patient recovery.

6. Power Equipment: Pioneer of Energy Transmission of Aluminum Alloy Die Castings

In the field of power equipment manufacturing, aluminum alloy die-castings have become key materials for power transmission and distribution equipment with their good conductivity, corrosion resistance and mechanical strength. The application of surface treatment technology has further improved its performance in power equipment.

In high-voltage switchgear, the shell of aluminum alloy die-casting is treated with special chemical plating to form a metal coating with excellent conductivity and corrosion resistance on the surface. This coating can not only improve the conductivity of the equipment, reduce resistance, and reduce the loss of electric energy during transmission, but also protect the equipment from corrosion in harsh natural environments and ensure the stable operation of the power system.

In the manufacture of power transformers, after the aluminum alloy die-cast heat sink is anodized, a uniform oxide film is formed on its surface, which greatly improves the heat dissipation efficiency and corrosion resistance of the heat sink. During the operation of the transformer, the heat sink can quickly dissipate the heat generated by the equipment, ensure the long-term stable operation of the transformer under high load, and provide reliable guarantee for power supply.

7. Mechanical Manufacturing: The Industrial Backbone of Aluminum Alloy Die Castings

In the field of mechanical manufacturing, aluminum alloy die-castings play an indispensable role as key components of various mechanical equipment. The application of surface treatment technology provides strong support for the wide application of aluminum alloy die-castings in this field.

In the manufacture of industrial robots, the robot arms and joint parts of aluminum alloy die-castings are precisely sprayed to form a layer of wear-resistant and corrosion-resistant coating on the surface. This coating can not only increase the service life of robot parts, but also ensure that the robot maintains high-precision motion control in complex industrial environments. In automated production lines such as automobile manufacturing and electronic production, these surface-treated aluminum alloy robot parts can operate stably for a long time, improving production efficiency and product quality.

In the manufacture of CNC machine tools, the surface hardness and wear resistance of aluminum alloy die-casting machine tool beds and worktables are significantly improved after anodizing. During the high-speed cutting and heavy-load processing of machine tools, these parts can withstand huge cutting forces and friction, ensuring the processing accuracy and stability of machine tools. At the same time, the aluminum alloy parts after anodizing also have good corrosion resistance and can maintain good performance during the long-term use of machine tools.

The continuous innovation and improvement of surface treatment technology has provided strong technical support for the wide application of aluminum alloy die-castings in various industries. Whether in automobile manufacturing, aerospace, or electronic appliances, architectural decoration, medical equipment, power equipment and machinery manufacturing, aluminum alloy die-castings that have undergone surface treatment have shown excellent performance and wide application potential. In the future, with the continuous advancement of science and technology and the continuous changes in market demand, aluminum alloy die-castings and their surface treatment technology will usher in a broader development space and continue to contribute to human industrial civilization and scientific and technological progress.