+86-13516964051

+86-13516964051 Aluminum Alloy Die-Casting Technology: The Core Foundation for Medical Device Reliability

Aluminum Alloy Die-Casting Technology: The Core Foundation for Medical Device Reliability

In the healthcare sector, "reliability" is the lifeline for measuring the value of equipment. From surgical robots operating with precision in the operating room, to monitors on 24/7 in the emergency room, to ultrasound diagnostic equipment frequently used in primary care settings, even the slightest malfunction can delay treatment and threaten patients' lives. Aluminum alloy die-casting technology, with its unique advantages in material properties, manufacturing precision, and structural stability, is becoming a key supporting technology for improving the reliability of medical equipment, providing a solid foundation for its safe operation.

I. The "Rigid Need for Reliability" in Medical Equipment: Why is Die-Casting Technology One of the Optimal Solutions?

Medical equipment has far higher reliability requirements than ordinary industrial products. This "rigid need" is reflected in three core dimensions: adaptability to extreme environments, long-term operational stability, and sustained precision performance. The high-temperature sterilization environment of the operating room, the 24-hour continuous operation of the ICU, and the bumpy transportation of ambulances require equipment components to withstand temperature fluctuations, vibration, shock, and chemical corrosion.

The imaging accuracy of diagnostic equipment and the dose control of therapeutic equipment rely on core structural components to maintain long-term dimensional stability at the millimeter or even micron level.

The medical industry's stringent GMP certification and ISO 13485 standards impose extremely stringent requirements on component consistency and cleanliness.

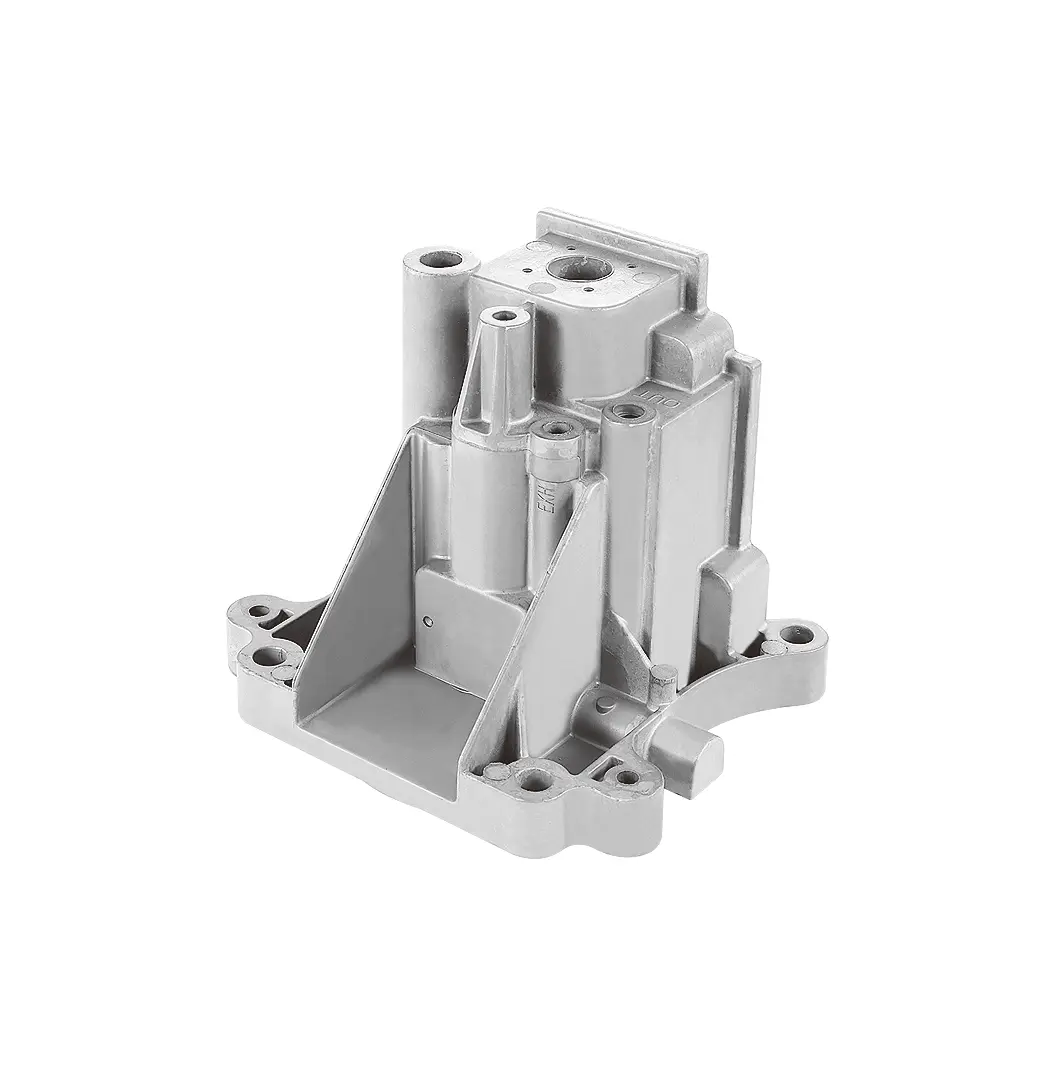

In traditional manufacturing processes, welds are prone to cracking due to stress concentration, forgings are costly and difficult to integrate complex structures, and 3D printed parts are limited in mass production stability and strength. Aluminum alloy die-casting technology, with its integrated molding process of "high-temperature melting - high-pressure filling - rapid solidification," perfectly meets the reliability requirements of medical equipment. It leverages the lightweight and corrosion-resistant properties of aluminum alloy to adapt to complex medical scenarios, while maintaining structural integrity and precision control through high-pressure molding, reducing the risk of failure from the very beginning.

II. Four Core Paths for Improving Medical Device Reliability Using Aluminum Alloy Die-Casting Technology

1. Material Property Customization: Balancing Strength, Lightweight, and Biocompatibility

Medical device component requirements vary widely: surgical instruments require high-hardness, wear-resistant materials, monitor housings require lightweight, impact-resistant structures, and blood testing equipment requires components with excellent biocompatibility.

Aluminum alloy die-casting technology enables precise customization of material properties through "alloy composition adjustment + Heat Treatment process optimization." For example, monitor housings die-cast from Al-Si-Mg alloys (such as A380) achieve a tensile strength exceeding 250 MPa and a density only one-third that of steel. This not only meets the device's drop resistance requirements but also reduces the burden on medical personnel. For the core flow path components of blood analyzers, an Al-Si-Cu alloy with an extremely low copper content is used. T6 heat treatment is used to eliminate internal stress, effectively preventing metal ion precipitation from interfering with test results. This also improves the component's corrosion resistance, extending its service life by more than three times that of traditional injection molded parts. In addition, the performance of die-cast aluminum alloy surfaces can be further optimized through processes such as anodizing and electrophoretic coating. For example, a 5-10μm anodic oxide film can be formed on the surface of the joint components of a surgical robot's robotic arm, improving wear resistance while also meeting the sterilization requirements of medical devices.

2. Structural Integrated Molding: Eliminating Assembly Risks and Improving Structural Stability

Core components of medical devices often contain complex cavities, thin walls, and reinforcing ribs. Traditional manufacturing methods often utilize "multiple-piece splicing + welding/bolting," which can easily lead to the following reliability risks: stress concentration at the joints can cause loosening and breakage after long-term use; assembly gaps can affect the device's sealing performance or motion accuracy; and the cumulative errors of multiple components can reduce the device's overall performance stability.

Aluminum alloy die-casting technology, with its "high-pressure, high-speed filling," enables the integrated molding of complex structures, fundamentally eliminating assembly risks. Taking the rotating bracket of a CT machine as an example, traditional processes require the bracket body, motor mount, and heat dissipation cavity to be individually machined and assembled, resulting in assembly errors exceeding 0.5mm. This can also lead to loosening of components after long-term rotation. Using an integrated die-Casting Process, the bracket can be formed entirely in one go. This not only eliminates assembly gaps and cumulative errors, maintaining dimensional accuracy within ±0.1mm, but also reduces weight by 30% through structural optimization, lowering the load on the rotating motor and improving the equipment's continuous operating stability by over 40%.

For the probe housing of an ultrasound diagnostic instrument, the die-casting process allows thin walls (as thin as 1.5mm) and complex curved surfaces to be integrated with the internal signal transmission cavity, eliminating signal transmission interference associated with traditional splicing processes and significantly improving the clarity and stability of ultrasound images.

3. High Precision and Consistency Control: Meeting the "Zero Error" Requirements of Medical Equipment

The reliability of medical equipment depends on the high precision and batch consistency of components. For example, the aperture accuracy of collimators in radiotherapy equipment directly impacts the accuracy of radiation dose control. An error exceeding 0.1mm can result in insufficient or excessive treatment doses. Similarly, poor dimensional consistency in the flow control components of infusion pumps can lead to variations in infusion accuracy between different devices, impacting treatment effectiveness.

Aluminum alloy die-casting technology achieves high-precision manufacturing through a combination of "mold precision control + process parameter optimization":

Molds are manufactured using high-precision CNC machining centers, achieving a cavity accuracy of ±0.02mm. Combined with precise guidance using guide pins and sleeves, this ensures that component dimensional deviations are controlled within ±0.05mm for each die-casting cycle.

Modern die-casting production lines are equipped with real-time monitoring systems that provide closed-loop control of key parameters such as molten aluminum alloy temperature (control accuracy ±5°C), filling pressure (±0.1MPa), and dwell time (±0.1s), minimizing component performance variations caused by process fluctuations. Production data from a medical device company shows that the dimensional consistency of infusion pump flow control valve cores produced using an aluminum alloy die-casting process can reach a CPK value (Process Capability Index) of over 1.67 in mass production, significantly higher than the 1.33 achieved with traditional machining. This reduces the flow accuracy error of infusion pumps from ±5% to within ±2%, fully meeting the stringent standards of the medical industry.

4. Lightweighting and Heat Dissipation Optimization: Extending Equipment Life and Improving Operational Safety

The "lightweight" of medical equipment not only affects ease of use but also directly impacts operational reliability. For example, mobile ultrasound machines and portable monitors require frequent movement. Excessive weight increases the operating burden on medical personnel and can also cause damage from accidental drops. For large equipment such as MRIs and PET-CT scans, the heat dissipation performance of core components directly determines the equipment's operational lifespan. Excessive temperatures can cause electronic component aging, accuracy drift, and even equipment downtime. Aluminum alloy die-casting technology offers inherent advantages in lightweighting and optimizing heat dissipation:

With a density of only 2.7g/cm³, die-cast aluminum alloy is 60% lighter than cast iron and 50% lighter than stainless steel. Mobile monitor housings made of die-cast aluminum alloy are 15% lighter than traditional ABS plastic housings, while offering two times the impact resistance, making them more portable and reducing the risk of damage from drops.

Aluminum alloy has a thermal conductivity of 120-200W/(m·K), 50-100 times that of ABS plastic. The die-casting process allows for integrated heat sink fins to be incorporated into the housings of core device components (such as power modules and motor driver boards), eliminating the need for additional heat sinks and improving heat dissipation efficiency by over 30%. The gradient amplifier housing of a certain brand of MRI equipment is manufactured using die-cast aluminum alloy. Combined with optimized internal heat dissipation channels, this keeps the amplifier's operating temperature stable below 45°C, extending the lifespan by 2-3 years compared to traditional heat dissipation structures.

III. Practical Case Study: Reliability Application of Aluminum Alloy Die-Casting Technology in Key Medical Devices

1. Surgical Robots: "Reliability Guarantee" for High-Precision Joint Components

The robotic arms of surgical robots must perform precise rotation, flexion, and extension within a confined surgical space. The precision and stability of the joint components directly determine surgical safety. A well-known medical device company uses a high-strength Al-Zn-Mg aluminum alloy die-cast for the robotic arm joints of surgical robots, optimizing them through the following technologies to improve reliability:

The mold utilizes a hot runner system to ensure uniform filling of the aluminum alloy melt, preventing defects such as pores and shrinkage within the joints.

After die-casting, T73 heat treatment is performed to eliminate internal stresses, resulting in a yield strength of over 300 MPa and a fatigue life exceeding 100,000 cycles.

The joint surfaces are precision-ground, and, with the interference fit of the bearings, dimensional accuracy is controlled to within ±0.01 mm. This joint component has undergone 1000 hours of continuous operation testing and exhibited no loosening or wear. Positioning accuracy remains within 0.1mm, fully meeting the stringent requirements of minimally invasive surgery.

2. Hemodialysis Machine: Long-Term Stability of Corrosion-Resistant Flow Path Components

The dialysate flow path components of hemodialysis machines come into direct contact with patient blood and dialysate, requiring excellent corrosion resistance and biocompatibility. The flow path components, die-cast from a lead-free Al-Si-Cu aluminum alloy, are enhanced through the following processes:

The die-casting process strictly controls impurity levels (iron and zinc content below 0.5%) to prevent metal ion precipitation;

The inner wall of the flow path is electrochemically polished to a surface roughness of Ra ≤ 0.8μm, reducing blood adhesion;

The entire surface is passivated to form a dense oxide film, providing salt spray corrosion resistance for over 1000 hours. After three years of continuous use in clinical applications, this flow channel component has shown no corrosion or leakage. The purity and flow stability of the dialysate remain within standard limits, reducing the risk of infection for patients due to device failure.

3. Portable Ultrasound Devices: Lightweight Housing for Impact Protection

Portable ultrasound devices must adapt to complex usage scenarios, such as ambulances and primary care settings. Impact resistance and lightweight housings are crucial. The ultrasound device housing, die-cast from A380 aluminum alloy, achieves improved reliability through structural optimization and process improvements:

Honeycomb-shaped reinforcement ribs within the housing improve impact resistance by 50% while increasing weight by 10%;

Vibration aging treatment is applied after die-casting to eliminate residual stress and prevent cracking in the housing due to temperature fluctuations;

The surface is finished with a matte electrophoretic coating, which provides both anti-slip properties and resistance to frequent wiping with disinfectants such as alcohol and iodine. The housing has undergone a 1.5-meter drop test (simulating an accidental drop) and showed no noticeable deformation. The internal electronic components remain intact, and the device continues to function normally, meeting the reliability requirements of emergency scenarios.

IV. Future Trends: How Can Die-Casting Technology Further Enhance the Reliability of Medical Equipment?

As medical devices evolve toward intelligent, minimally invasive, and portable devices, aluminum alloy die-casting technology is continuously evolving, injecting new momentum into reliability improvements:

1. Integrated Die-Casting: A Breakthrough for Ultra-Large Sizes and Ultra-Complex Structures

For large components such as surgical robot arms and MRI equipment frames, the "ultra-large die-Casting Mold + multi-cylinder simultaneous injection" technology enables integrated molding of single components weighing over 50 kg, further reducing assembly steps and improving overall structural rigidity and stability.

2. Digital and Intelligent Process Control

The introduction of an AI visual inspection system enables real-time identification of surface defects and internal porosity in die-Cast Parts, with an inspection accuracy of 0.01mm, over 10 times greater efficiency than manual inspection. Combined with digital twin technology, it simulates the temperature and stress distribution during the die-casting process, enabling pre-emptive optimization of process parameters and increasing component qualification rates from 95% to over 99%.

3. Integration of New Alloys and Composite Processes

Development of an aluminum-carbon fiber composite die-cast material, which maintains the lightweight advantages of aluminum alloy while increasing strength by over 20%, making it suitable for ultra-high-precision core components of radiotherapy equipment. Exploring the hybrid process of die-casting and 3D printing allows complex functional structures to be printed directly onto the die-cast substrate, eliminating secondary assembly and improving the integration and reliability of the equipment.