+86-13516964051

+86-13516964051 Aluminum Alloy Die-Casting Surface Treatment

Aluminum Alloy Die-Casting Surface Treatment

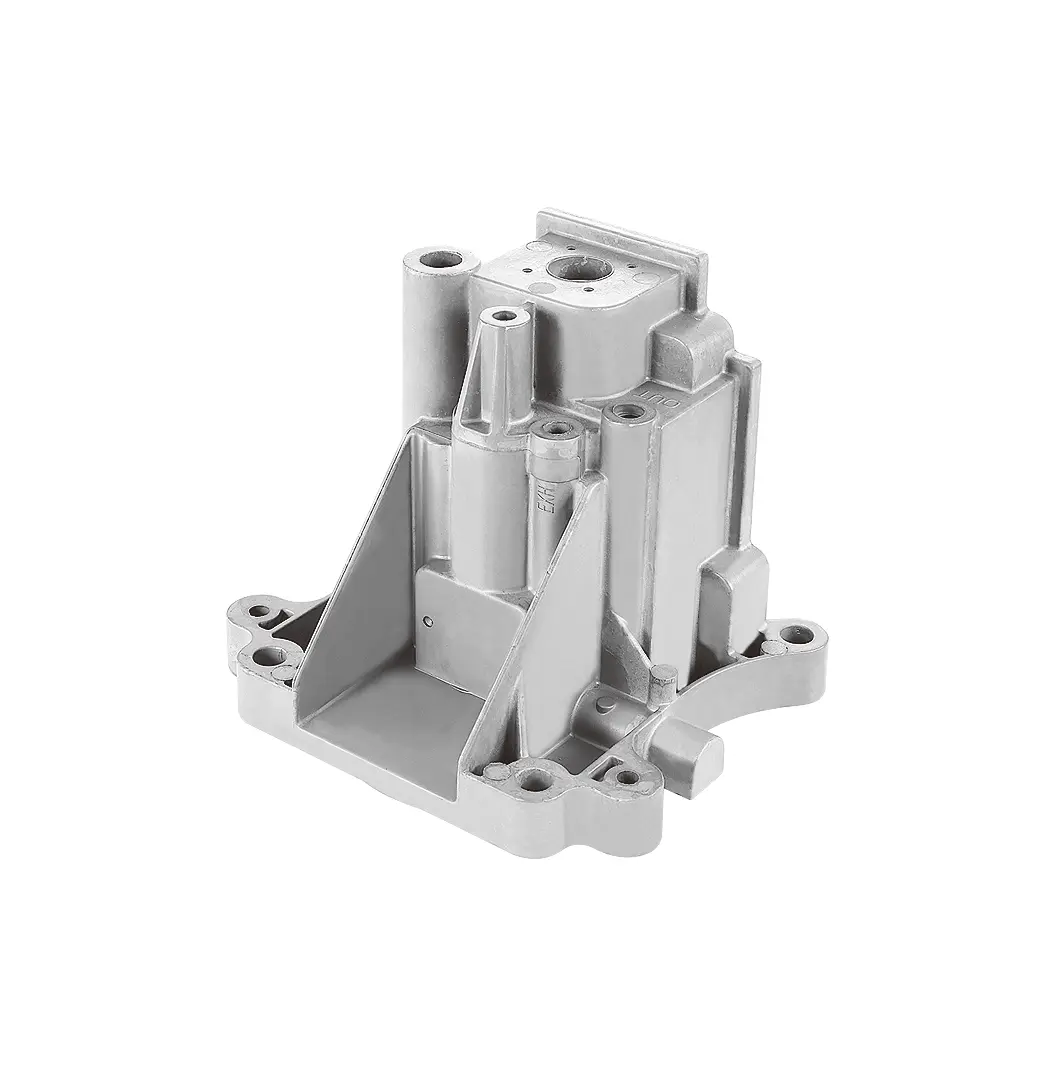

In the aluminum alloy die-casting industry, "forming" is only the starting point of the manufacturing process; surface treatment is the key factor that determines a product's appearance, performance, and market competitiveness. Whether it's the stringent corrosion resistance requirements of automotive parts, the exquisite appearance of consumer electronics, or the fundamental wear resistance requirements of industrial equipment, scientific and rational surface treatment processes are essential. This article will comprehensively analyze the core value, mainstream processes, selection logic, and future trends of aluminum alloy die-casting surface treatment, helping companies achieve dual optimization of product quality and cost control.

I. Why is surface treatment necessary for aluminum alloy die-casting? Three core values are irreplaceable

Aluminum alloy die-casting, with its advantages of high forming efficiency and strong adaptability to complex structures, is widely used in the automotive, 3C, new energy, and construction machinery industries. However, die-cast blanks have inherent defects: surface roughness, pinholes and shrinkage, and uneven oxide films. Furthermore, pure aluminum has weak corrosion and wear resistance. The core function of surface treatment is to "correct defects and enhance advantages" through physical, chemical, or electrochemical means. This can be summarized into three key benefits:

1. Enhanced Protection: A "Protective Umbrella" that Extends Product Lifespan

Aluminum alloys are susceptible to corrosion in harsh environments such as moisture, acidity, and alkalinity. Surface treatment forms a dense protective film on the workpiece surface, isolating it from corrosive media such as water, oxygen, and salt. For example, after phosphating and electrophoresis treatment, the salt spray resistance of aluminum alloy control arms in automotive chassis can be increased from less than 24 hours for the original part to over 1,000 hours, significantly reducing after-sales failure rates. Anodizing treatment is used on battery casings in new energy vehicles, not only protecting them from electrolyte corrosion but also improving insulation performance and ensuring battery safety.

2. Enhanced Appearance: Meeting Diverse Market Aesthetic Needs

In the consumer electronics and smart home sectors, product appearance requirements are becoming increasingly stringent. From matte to high gloss, from solid color to gradient, and from metallic textures to simulated wood grain or carbon fiber effects, surface treatment is the core means of achieving these visual effects. Taking the smartphone midframe as an example, a combination of sandblasting, anodizing, and brushing creates a delicate matte feel and refined metallic luster. Spray coating, on the other hand, allows for a wide range of color combinations, satisfying the design needs of different brands.

3. Functional Enhancement: A "Booster" for Expanding Product Applications

Beyond protection and aesthetics, surface treatment can also impart special functions to aluminum alloy die-Cast Parts. For example, hard anodizing can achieve a surface hardness exceeding HV300 for aluminum alloy joint components in industrial robots, making their wear resistance comparable to that of steel. Chemical conversion coating treatment on heat dissipation modules enhances surface hydrophilicity and heat dissipation efficiency. Aluminum alloy components for medical devices undergo passivation treatment to meet biocompatibility requirements and prevent adverse reactions from human contact.

II. A Comprehensive Analysis of Mainstream Aluminum Alloy Die-Casting Surface Treatment Processes: Characteristics, Applications, Advantages and Disadvantages

A wide variety of aluminum alloy die-casting surface treatment processes exist, and the principles, effects, and applicable scenarios of each process vary significantly. Companies need to select the most appropriate process based on their product's material, structure, performance requirements, and cost budget. The following are the six most widely used process types:

1. Chemical Conversion Coating: A Low-Cost Basic Protection Solution

Principle: Aluminum alloy die-castings are immersed in a chemical solution (such as chromate, phosphate, or chromium-free passivation agents). A chemical reaction forms an inorganic film 0.5-10μm thick on the surface.

Common Types:

Chromate Conversion Coating: Offers strong protection, but contains chromium, which does not meet environmental standards and is being phased out.

Phosphate Conversion Coating: Mainly used for pre-coating pre-treatment to enhance coating adhesion.

Chromium-free passivation coatings (such as zirconium-titanium-based): Environmentally friendly and corrosion-resistant, they are the current mainstream basic protection process. Advantages: Simple process, low cost, fast processing speed, suitable for mass production; Disadvantages: Thin film layer, limited protection when used alone, mostly used as a pretreatment for subsequent coatings; Typical applications: Pretreatment of automotive parts before painting, base treatment of home appliance housings, basic protection for hardware.

2. Anodizing: Ideal for high hardness and high appearance

Principle: The aluminum alloy die-casting serves as the anode and is placed in an electrolyte solution (such as sulfuric acid or oxalic acid). Electrolysis forms an oxide film (Al₂O₃) with a thickness of 5-200μm on the surface.

Common Types:

Ordinary anodizing (sulfuric acid): The film is uniform, highly absorbent, and can be dyed, suitable for exterior parts;

Hard anodizing (oxalic acid or sulfuric acid-oxalic acid mixed): The film has high hardness and excellent wear resistance, suitable for functional parts;

Porcelain anodizing: The film has a porcelain-like appearance and strong insulation properties, suitable for electronic components. Advantages: Excellent corrosion and wear resistance, customizable appearance (dying, sandblasting, oxidation, etc.), and strong adhesion between the film and substrate. Disadvantages: Complex process, high cost, requirements for workpiece structure (such as avoiding deep holes and narrow gaps to prevent uneven film coating), and slight dimensional increase after oxidation. Typical Applications: Smartphone midframes, laptop casings, drone bodies, industrial robot arms, heat sinks.

3. Spraying: A versatile coating solution with rich colors.

Principle: A coating (such as powder, paint, or electrophoretic paint) is evenly applied to the surface of the aluminum alloy die-casting using a spray gun or electrostatic spray equipment. The coating forms after curing. Common Types:

Powder Coating: Utilizes epoxy resin, polyester, and other powder coatings, with a coating thickness of 60-150μm and strong weather and impact resistance.

Liquid Spraying (Painting): Offers delicate colors and high gloss, capable of achieving matte, glossy, and metallic finishes.

Electrophoretic Spraying: Offers excellent coating uniformity and strong adhesion, making it suitable for complex structural parts and more environmentally friendly than traditional painting.

Advantages: Offers a wide range of colors, a variety of finishes, and versatile coating functions (such as weather resistance, insulation, and anti-slip properties).

Disadvantages: Coatings are susceptible to aging, may peel and fade over time, and require high pre-treatment requirements (thorough degreasing and rust removal).

Typical Applications: Automotive body panels, appliance housings (refrigerators, washing machines), outdoor lighting, and furniture hardware.

4. Electroplating: A high-end metallic upgrade.

Principle: Electrolysis is used to deposit a layer of metal or alloy (such as nickel, chromium, zinc, copper, or gold) onto the surface of aluminum alloy die-cast parts. Because aluminum alloy surfaces are prone to forming oxide films, special pretreatment (such as zinc immersion or nickel plating) is required before electroplating to enhance the coating's adhesion.

Common Types:

Galvanizing: Low cost, good protection, suitable for general hardware;

Nickel plating: Better corrosion and wear resistance than zinc plating, with a silvery-white appearance;

Chrome plating: High hardness and strong reflectivity, suitable for components that combine decorative and functional features;

Gold/Silver plating: Primarily used for conductive and soldering areas of electronic components.

Advantages: Strong metallic texture, decorative effect, and some coatings can improve conductivity and weldability.

Disadvantages: Complex process, high cost, risk of heavy metal contamination, relatively weak adhesion between the coating and the substrate, prone to peeling.

Typical Applications: High-end bathroom hardware, electronic connectors, decorative automotive parts, and precision instrument housings.

5. Sandblasting: A Pre-treatment Process for Creating a Fine Texture

Principle: Compressed air is used to spray abrasives (such as quartz sand, aluminum oxide sand, glass beads, etc.) at high speed onto the surface of aluminum alloy die-castings. The impact of the abrasive removes surface scale, burrs, and oil stains, while simultaneously creating a rough, matte finish.

Advantages: Simple operation, high efficiency, improves surface roughness, and enhances the adhesion of subsequent coatings.

Disadvantages: Used alone, it provides no protective effect and is only used as part of a pre-treatment or cosmetic treatment.

Typical Applications: Surface pre-treatment before anodizing, roughening before painting, and for exterior parts requiring a matte finish (such as speaker housings and camera bodies).

6. Polishing: A Fine Process for Achieving a High-Gloss Mirror Finish

Principle: Through mechanical grinding (such as cloth wheel polishing, grinding wheel polishing) or chemical polishing or electrolytic polishing, minute surface irregularities on aluminum alloy die-castings are removed, creating a smooth, mirror-like finish. Common Types:

Mechanical Polishing: Suitable for simple shapes, can achieve a high gloss, but is prone to scratches.

Chemical Polishing: Simple process, suitable for complex structures, but slightly lower gloss than mechanical polishing.

Electrolytic Polishing: Combining chemical and electrolytic processes, it achieves high gloss, a uniform surface, and is environmentally friendly.

Advantages: Provides a refined appearance, strong reflectivity, and enhances the product's premium feel.

Disadvantages: High cost, low efficiency, requires high surface flatness, and requires additional protective processes (such as electroplating or anodizing) after polishing.

Typical Applications: High-end kitchenware, luxury accessories, stage lighting, and decorative artwork.

III. How to Select a Product Scientifically? Four Core Factors Determine the Process Plan

When selecting an aluminum alloy die-casting surface treatment process, avoid the extremes of "blindly pursuing high-end" or "purely controlling costs." Instead, consider the actual product needs for a comprehensive assessment. The following four core factors are key to selection:

1. Product Application and Performance Requirements

This is the primary basis for selection. For example:

Automotive powertrain components (such as cylinder blocks and oil pans): require high-temperature resistance and oil corrosion resistance, so phosphating + electrophoresis or hard anodizing are preferred.

Outdoor lighting housings: require UV and rain resistance, so powder coating (polyester) or fluorocarbon spraying is suitable.

Precision electronic connectors: require good conductivity and easy soldering, so nickel plating + gold plating is recommended.

Consumer electronic exterior parts: require a balance between aesthetics and wear resistance, so sandblasting + anodizing or high-gloss polishing + electroplating is recommended.

2. Product Structure and Dimensional Accuracy

For complex structural parts, consider the process adaptability. For example:

For die-cast parts with deep holes or narrow slots: Avoid anodizing (which can lead to uneven coatings) and electroplating (which can lead to plating buildup). Spraying or chemical conversion coating is preferred.

For parts requiring high dimensional accuracy: Consider the impact of the process on dimensions (e.g., anodizing can increase dimensions by 0.5-5μm, while electroplating can increase dimensions by 1-10μm). Allow for machining allowance when selecting.

3. Cost Budget and Production Efficiency

The costs of different processes vary significantly, so a balance between performance and cost is crucial. For example:

For high-volume, low-value-added hardware: Chromium-free passivation or galvanizing are cost-effective options.

For mid- to high-end exterior parts: Sandblasting + anodizing offers moderate costs and stable results, making it suitable for mass production.

For high-end custom parts: Electropolishing + electroplating or porcelain anodizing is more expensive, but can meet high-end needs.

Production efficiency should also be considered: Chemical conversion coating and sandblasting are fast and suitable for assembly line production, while polishing and hard anodizing are less efficient and suitable for small-batch customization.

4. Environmental Protection and Policy Requirements

With increasingly stringent environmental regulations, chromium- and cyanide-containing processes (such as traditional chromate passivation and cyanide electroplating) have been restricted. Companies should prioritize environmentally friendly processes, such as chromium-free passivation, water-based paint spraying, and cyanide-free electroplating, to avoid production impacts due to environmental issues.

IV. Industry Trends: Environmentally Friendly, Functionalized, and Integrated Development

With manufacturing upgrades and evolving market demand, the aluminum alloy die-casting surface treatment industry is developing in three major directions:

1. Environmentally Friendly Processes Becoming Mainstream

Driven by the "Dual Carbon" policy, environmentally friendly processes will gradually replace traditional, highly polluting ones. For example, chromate passivation has completely replaced chromate passivation; water-based powder coatings and ultraviolet (UV) coatings have become new spray coating options due to their low volatile organic compound (VOC) emissions; and wastewater- and gas-free vacuum coating processes, such as physical vapor deposition (PVD), are increasingly widely used in high-end applications.

2. Increasing Demand for Multifunctionality

Single-function surface treatments are no longer sufficient to meet the demands of high-end products. Composite processes combining "protection + appearance + special functions" are becoming a trend. For example, the onboard radar housings of new energy vehicles must simultaneously provide weather resistance, electromagnetic shielding, and aesthetics. A composite process combining "chromium-free passivation + conductive spray coating + weather-resistant powder coating" achieves these multiple functions. Smartwatch cases utilize "sandblasting + anodizing + PVD coating" to ensure wear resistance while achieving a high-end metallic finish.

3. Process Integration and Automation Upgrades

To improve production efficiency and product consistency, surface treatment is shifting from discrete processes to integrated production lines. For example, processes such as "degreasing → rust removal → passivation → spray coating → curing" are integrated into a continuous production line, reducing workpiece transfer time. Furthermore, the increasing use of automated equipment (such as robotic spray coating and fully automated anodizing lines) not only reduces labor costs but also enables precise control of process parameters to avoid human error.

V. Conclusion: Surface Treatment is the "Second Creation" of Aluminum Alloy Die-Casting Products

Surface treatment of aluminum alloy die-casting is not only a finishing touch that adds a finishing touch to the exterior, but also a core component for improving quality and efficiency. From basic protective treatments to high-end functional upgrades, and from traditional chemical processes to environmentally friendly physical ones, advances in surface treatment technology are driving aluminum alloy die-casting into a wider range of applications.