+86-13516964051

+86-13516964051 Gravity Die Casting for Aluminum: Expert ODM Manufacturing & Service Solutions

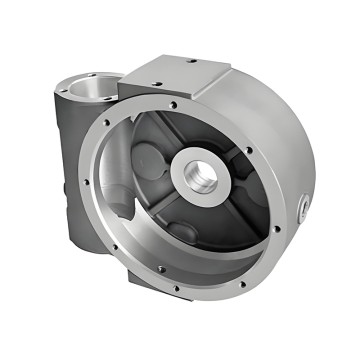

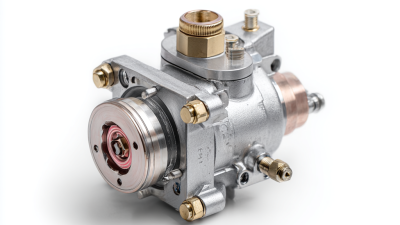

At Yongkang Hantai Industry And Trade Co., Ltd., we excel in providing tailored solutions for **Gravity Die Casting Aluminium**. As a seasoned manufacturer, we prioritize precision and durability in our die casting processes. Our ODM services foster close collaboration, ensuring that your design requirements are met with utmost accuracy. With state-of-the-art facilities and a skilled team, we are dedicated to delivering exceptional service throughout the production journey. We strive to build enduring partnerships and offer reliable support and flexible solutions across various sectors, including automotive and electronics. Trust us for all your custom aluminium component needs, as we are committed to fulfilling them efficiently and effectively. Let's bring your projects to fruition together!10 tips Gravity Die Casting Aluminium Pioneers in the Field Where Service Meets Innovation

In the ever-evolving landscape of die casting, Yongkang Hantai Industry & Trade Co., Ltd. stands out as a beacon of innovation and quality. Established in 1997, our company has dedicated itself to technological advancements and continuous improvement, particularly within the automotive sector. As we share our expertise, we've compiled ten essential tips to navigate the complexities of gravity die casting aluminum, aiming to enhance both efficiency and product quality. Firstly, understanding the fundamentals of material selection is crucial. Aluminum's lightweight characteristics make it a preferred choice in automotive applications, allowing for fuel efficiency while maintaining structural integrity. Secondly, investing in advanced Casting Techniques can significantly reduce production costs and time. Our commitment to innovation means we constantly explore new technologies that lead to better results. Thirdly, prioritizing quality control throughout the production process ensures that every part meets stringent industry standards, thereby reducing the likelihood of defects and enhancing customer satisfaction. Additionally, effective communication and collaboration with suppliers create a seamless supply chain, which is vital for meeting delivery deadlines in the fast-paced automotive market. It is also essential to stay updated on industry trends and regulations, as this knowledge can drive strategic decision-making. By combining these practices with our unwavering commitment to quality, Yongkang Hantai not only meets but exceeds the expectations of global buyers, reinforcing our position as pioneers in the gravity die casting aluminum sector where service genuinely meets innovation.

10 Tips Gravity Die Casting Aluminium Pioneers in the Field Where Service Meets Innovation

| Tip Number | Tip Description | Benefits | Example Application |

|---|---|---|---|

| 1 | Optimize Mold Design | Improves quality and reduces defects | Automotive parts |

| 2 | Choose the Right Aluminum Alloy | Enhances strength and corrosion resistance | Aerospace components |

| 3 | Implement Advanced Quality Control | Reduces waste and improves consistency | Consumer electronics |

| 4 | Utilize Efficient Cooling Techniques | Shortens cycle times | Industrial machinery |

| 5 | Automate the Casting Process | Increases production efficiency | Home appliances |

| 6 | Regular Maintenance of Equipment | Prevents unforeseen breakdowns | Manufacturing tools |

| 7 | Invest in Staff Training | Enhances skill levels and productivity | All sectors |

| 8 | Improve Material Handling | Reduces handling time and costs | Warehouse operations |

| 9 | Focus on Sustainable Practices | Minimizes environmental impact | Recycling aluminum |

| 10 | Collaborate with Suppliers | Ensures material quality and consistency | Component manufacturing |

China’s Best-Selling Gravity Die Casting Aluminium Service Exceeds Industry Benchmarks

C

Carter Baker

I could not be happier with the quality of this product! Their customer service team was quick to respond and highly knowledgeable.

22 May 2025

D

Dominic Wilson

The quality is superb! The customer service team helped me without any delays, showcasing their expertise.

19 June 2025

K

Kinsley Bell

The quality is impressive! The support staff was professional, knowledgeable, and eager to help.

10 May 2025

A

Addison Harris

Amazing product quality! The support staff were resourceful and incredibly professional, addressing all my needs.

14 May 2025

B

Bella Lee

Wonderful product quality from top to bottom! The customer service was professional and attentive to my needs.

18 May 2025

R

Ronan Collins

This product is exactly what I was looking for! The support staff were informative and genuinely helpful.

05 July 2025