+86-13516964051

+86-13516964051 Die Casting Disadvantages: Key Insights for Suppliers and Service Providers

When considering die casting, it's important to weigh its disadvantages along with the benefits. As a seasoned supplier, I recognize that die casting offers precision and cost-efficiency but can also present challenges such as extended tooling lead times and limited material choices. At Yongkang Hantai Industry And Trade Co., Ltd., we prioritize solving these challenges for our ODM partners. Our factory employs cutting-edge techniques to reduce lead times and provides customized solutions for greater material flexibility. Our dedication to quality and exceptional customer service distinguishes us in the industry, ensuring you receive the best products tailored to your needs while navigating the complexities of die casting. Partner with us to tackle challenges and enhance your project's success.How To Die Casting Disadvantages Outperforms the Competition Where Service Meets Innovation

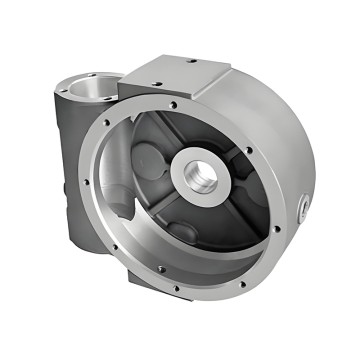

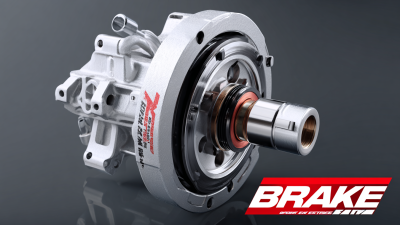

In today's competitive manufacturing landscape, many industries, especially automotive, seek innovative solutions that can redefine quality and efficiency. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we understand that achieving excellence in die casting requires not just advanced technology but a deep commitment to quality improvement. Our focus on integrating service with innovation allows us to stand out from competitors, ensuring that our clients receive not only high-quality parts but also exceptional support throughout their procurement process. Die casting, while offering numerous advantages such as precision and durability, also has its disadvantages. However, we believe that understanding these challenges is crucial for global buyers looking to optimize their supply chains. Our approach involves leveraging cutting-edge technology and a dedicated team that consistently evaluates and enhances our processes. By prioritizing quality control and fostering innovation, we mitigate the typical drawbacks associated with die casting, ensuring that our products not only meet but exceed industry standards. This commitment positions us as a preferred partner for procurement agents seeking reliable, high-performance components in the automotive sector. By choosing Yongkang Hantai, global buyers can be assured of a seamless experience from inquiry to delivery. Our combination of innovative techniques and personalized service ensures that we meet our clients' diverse needs while maintaining the highest standards of quality. As the automotive industry continues to evolve, we invite you to partner with us—where our dedication to integration of service and innovation helps you thrive in a competitive marketplace.

How To Die Casting Disadvantages Outperforms the Competition Where Service Meets Innovation

| Feature | Die Casting Advantages | Die Casting Disadvantages | Competitive Edge |

|---|---|---|---|

| Production Speed | High throughput and quick cycle times | High initial setup costs | Faster delivery times due to efficient processes |

| Dimensional Accuracy | Excellent precision in tolerances | Limited flexibility in design modifications | Ability to produce complex shapes efficiently |

| Material Options | Wide range of materials available | Not suitable for all material types | Use of innovative alloys for improved performance |

| Surface Finish | Smooth surface finishes reduce post-processing | Surface imperfections can occur | Advanced surface treatments available to enhance quality |

| Weight Efficiency | Lightweight components reduce overall weight | Limited to certain density and strength requirements | Innovative designs maximize strength-to-weight ratio |

Tips & Tricks for Die Casting Disadvantages Is The Best Manufacturer

N

Noah Clark

Impressive product quality! The after-sales service team went above and beyond to assist me, showcasing their professionalism. An excellent choice!

01 June 2025

A

Avery King

Absolutely brilliant product! The after-sales service was remarkable, showcasing knowledge and a genuine desire to help.

11 May 2025

A

Alexander Young

What a fantastic product! I was pleasantly surprised by how knowledgeable and friendly the customer service team was.

07 June 2025

L

Luna Moore

The craftsmanship is amazing! Their customer support team was incredibly helpful and knowledgeable.

03 June 2025

Z

Zoe Hill

Outstanding quality and performance! I was amazed by the professionalism and efficiency of the support team.

03 July 2025

E

Elena Carter

Impressive product quality! The professionalism exhibited by the support staff made my experience extremely positive.

03 June 2025