+86-13516964051

+86-13516964051

In the realm of manufacturing, the selection of the right Aluminum Die Casting Mould is a pivotal decision that can significantly influence production efficiency and product quality. As John Smith, a renowned expert in the die casting industry, aptly stated, "The longevity and performance of your products depend largely on the quality of the mould you choose." This underscores the importance of making informed choices when it comes to selecting an Aluminum Die Casting Mould.

Investing time and resources into understanding the nuances of die casting moulds can lead to enhanced operational performance and reduced costs in the long run. With the proliferation of technological advancements and varying production needs, it is crucial for manufacturers to stay abreast of the essential factors that contribute to effective die casting. In this article, we will delve into ten indispensable tips that will guide you in selecting the best Aluminum Die Casting Mould to fulfill your specific production requirements. Whether you are a seasoned professional or new to the industry, these insights aim to equip you with the knowledge necessary for making astute choices in your die casting endeavors.

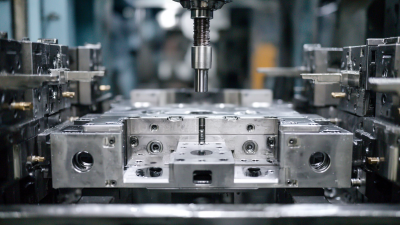

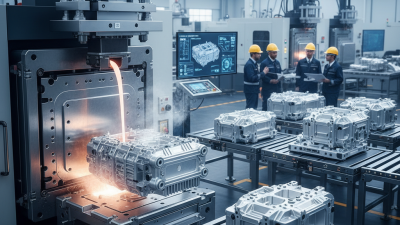

Aluminum die casting is a manufacturing process that involves creating precise parts by forcing molten aluminum into molds under high pressure. This technique is widely utilized across various industries due to its ability to produce complex shapes with excellent dimensional accuracy and surface finish. The process is favored for its efficiency, allowing for rapid production rates and consistent quality, making it ideal for high-volume applications such as automotive components, consumer electronics, and industrial machinery.

One of the key advantages of aluminum die casting is its strength-to-weight ratio, which is particularly beneficial in sectors where lightweight components are essential, such as aerospace and automotive engineering. Additionally, aluminum’s resistance to corrosion enhances the longevity of the cast parts, allowing manufacturers to meet the increasing demands for durability and performance. With advancements in technologies, aluminum die casting continues to evolve, offering innovative solutions that cater to a diverse array of applications while ensuring sustainability through recyclable materials. This makes understanding the fundamentals of aluminum die casting crucial for industries looking to implement cost-effective and high-performance manufacturing processes.

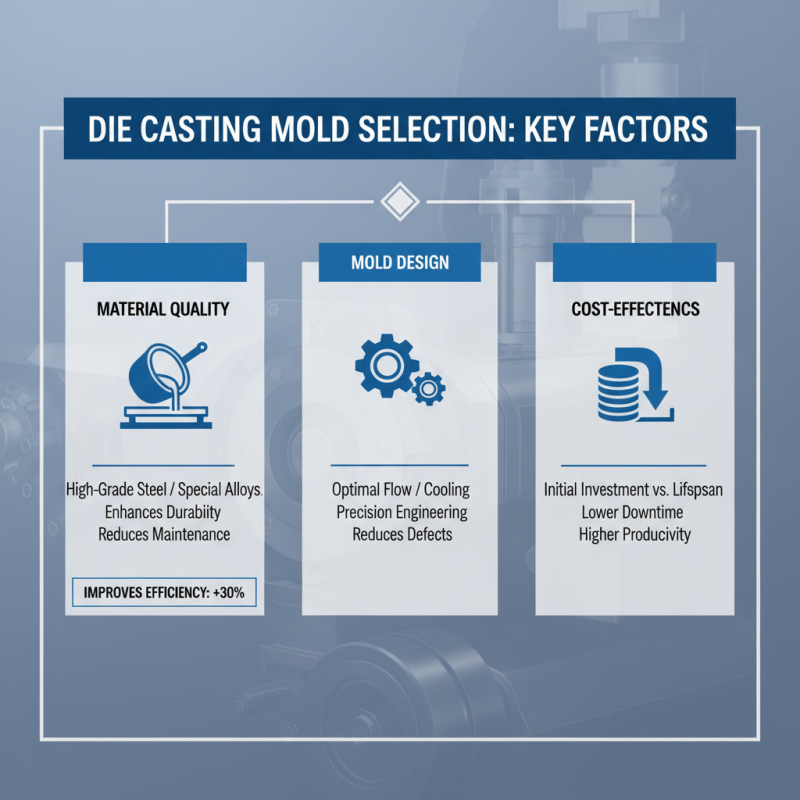

When selecting die casting moulds, several key factors must be taken into account to ensure efficiency, quality, and cost-effectiveness. One of the primary considerations is the material quality used in the mould construction. High-grade materials such as steel or special alloys can significantly enhance the durability of the mould, allowing for longer production runs and reducing maintenance costs. According to industry reports, investing in high-quality moulds can improve production efficiency by up to 30%, minimizing downtime due to wear and tear.

Another crucial factor is the design intricacies of the die casting mould. The complexity of part geometry should align with the capabilities of the die casting process to avoid defects such as air traps or insufficient filling. Advanced computer-aided design (CAD) tools can aid in optimizing mould design, ensuring that the final product meets dimensional accuracy and surface finish requirements. Data from the Aluminium Association indicates that well-designed moulds can reduce scrap rates by as much as 20%, highlighting the financial benefits of effective design strategies.

Furthermore, the mould's thermal management system plays a significant role in achieving optimal cycle times and product quality. Maintaining precise temperature control throughout the die casting process is essential for preventing defects related to thermal stress. Industry standards suggest that an efficient cooling system can cut cycle times by approximately 15-25%. By carefully evaluating these factors during the selection process, manufacturers can significantly enhance their die casting operations and deliver superior products to their clients.

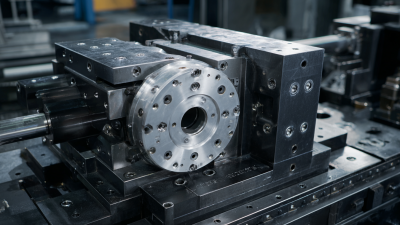

When it comes to selecting the right aluminum die casting mould, evaluating the material quality is crucial for ensuring durability and performance. High-quality aluminum alloys, such as those with additions of silicon or magnesium, not only enhance the mould's strength but also provide resistance to wear and corrosion. This is particularly important as moulds are subjected to repetitive stress and thermal cycles during the casting process. Opting for materials that have been tested for fatigue resistance can greatly extend the lifespan of the mould, reducing the frequency of replacements and maintenance.

In addition to alloy selection, the fabrication process plays a significant role in the overall quality of the die casting mould. Employing advanced machining techniques ensures precise dimensions and surface finishes, which are essential for achieving optimal castings. The integration of heat treatment processes can also enhance the mechanical properties of the mould, allowing it to withstand higher operational pressures. Furthermore, closely examining the manufacturing standards and certifications of the materials used can provide reassurance about their quality, ultimately leading to improved productivity and lower costs over time.

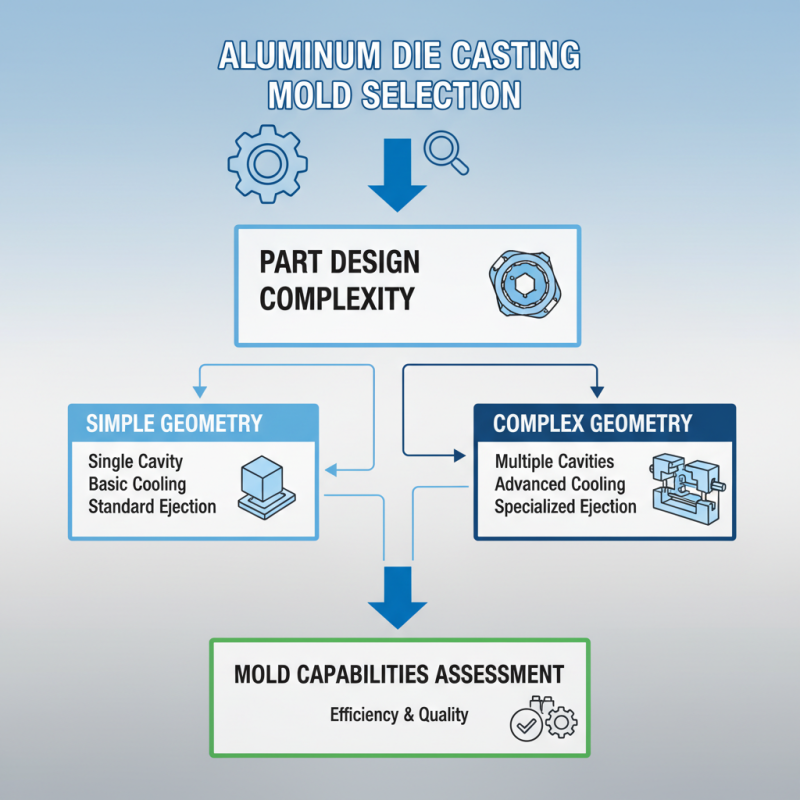

When selecting an aluminum die casting mould, one of the most critical factors to consider is the design complexity of the part being produced. The intricacies of the design can significantly influence the choice of mould, as more complex geometries often necessitate advanced mould features like multiple cavities, intricate cooling systems, or specialized ejection mechanisms. Assessing the design complexity helps in determining the required mould capabilities, which can directly affect production efficiency and the overall quality of the final product.

Additionally, the impact of design complexity on mould choice extends to cost and lead time. Moulds that are designed to accommodate complex shapes typically require more advanced manufacturing techniques, which can increase production costs and time. It is essential to strike a balance between design requirements and production feasibility. Simplifying certain aspects of the design may help to reduce these factors without sacrificing the integrity and functionality of the part. Therefore, a thorough analysis of the design before mould selection is vital to ensure an optimal production process and successful outcomes.

When it comes to procuring aluminum die casting molds, cost-efficiency is a primary concern for many manufacturers. Understanding the different factors that contribute to mold costs can significantly impact your overall budget. It is crucial to assess the initial investment versus long-term savings. Higher upfront costs may lead to better quality, durability, and precision, which can ultimately reduce maintenance and replacement needs over time. Investing in reliable molds can optimize production processes, minimizing defects and maximizing output, thereby enhancing overall efficiency.

Another vital consideration is the total cost of ownership. This includes not only the initial purchase price but also factors such as tooling life, production rates, and repair expenses. By analyzing these elements, you can make more informed decisions about the type of mold to choose. It's wise to compare quotes from different suppliers to understand the market rate, but be wary of prices that seem too low, as they may indicate compromised quality or service. Balancing cost with performance and reliability will ensure you achieve a favorable return on your investment.