+86-13516964051

+86-13516964051

When considering manufacturing options, Aluminum Die Casting Parts stand out as a strong choice. The lightweight properties of aluminum make these parts ideal for various applications. They provide excellent strength and durability, which can reduce the need for frequent replacements.

Aluminum Die Casting Parts also offer design flexibility. This permits intricate shapes and designs, which traditional manufacturing may not achieve. However, some designs may lead to complexities in casting. It's essential to consider the challenges involved in this process.

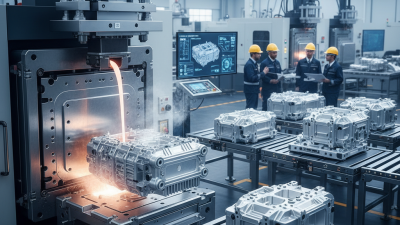

Using Aluminum Die Casting Parts can optimize production efficiency. Their high production speed can significantly reduce lead times. Yet, maintaining quality in high-volume production demands careful attention to detail. Balancing speed and quality is crucial for successful manufacturing outcomes.

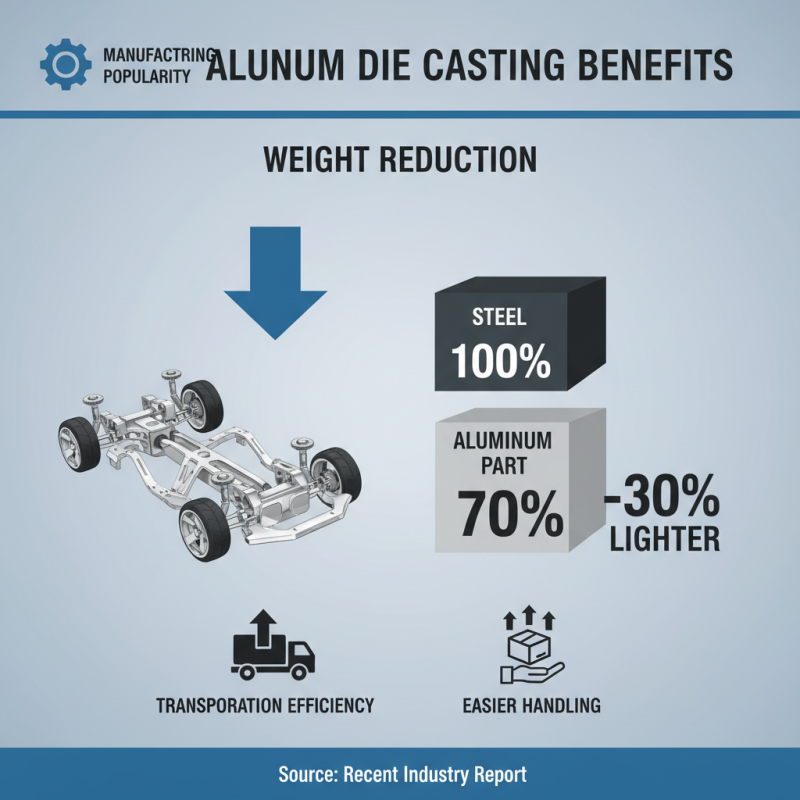

Aluminum die casting has gained popularity in various manufacturing sectors. One of its main benefits is the lightweight nature of aluminum. Parts made from aluminum can drastically reduce overall product weight. According to a recent industry report, aluminum parts can weigh up to 30% less than their steel counterparts. This weight reduction often leads to improved efficiency in transportation and handling.

Moreover, aluminum die casting provides excellent strength-to-weight ratios. Despite being lightweight, aluminum components maintain impressive structural integrity. This property allows manufacturers to design intricate and durable products. For example, the automotive industry leverages this quality to produce complex engine components. The precision of aluminum die casting can result in tolerances as tight as ±0.1 mm. This precision is crucial for ensuring proper fit and function in assemblies.

However, it’s worth noting that there are challenges in using aluminum die casting. Some manufacturers may experience higher initial tooling costs. Additionally, the recycling process for aluminum can be more demanding than for other materials. These aspects might lead to hesitation for some manufacturers. Yet, the long-term benefits, such as reduced weight and enhanced durability, often justify these upfront investment concerns.

Aluminum die casting parts are increasingly popular in manufacturing. They offer unique characteristics that make them ideal for various applications. One key feature is their lightweight nature. This makes them easier to handle during production. It's crucial for industries that require efficient operations.

Another important aspect is their excellent strength-to-weight ratio. Aluminum parts can withstand high stress while remaining light. This is especially beneficial in sectors like automotive and aerospace. However, achieving the perfect balance often requires precise engineering. Suboptimal designs can lead to weak spots.

Surface finish is also a notable quality of aluminum die casting. Parts can be produced with smooth surfaces, reducing the need for extra finishing work. This can save time and cost in projects. Nonetheless, inconsistencies in surface quality can occur. Manufacturers need to implement stringent quality checks to avoid issues.

When considering metal casting methods, aluminum die casting stands out. It offers precision and the ability to produce complex shapes. Compared to sand casting, which can be slower and less precise, aluminum die casting gives faster and more consistent results. The surface finish of die-cast parts is typically smoother, reducing the need for additional machining.

However, the initial cost of die casting molds can be high. This may be a challenge for small-scale operations. Still, for mass production, the long-term savings often outweigh these initial expenses. You save on labor and material waste.

Tips: Invest time in designing your part before starting the die casting process. A well-thought-out design can decrease production time and costs. Always consider the type of aluminum alloy you'll use, as it affects durability and weight. Be aware that die casting isn't always ideal for very large parts due to size limitations.

Aluminum die casting is increasingly popular across several industries. It offers significant advantages, such as lightweight structures and corrosion resistance. According to a recent industry report, the aluminum die casting market is expected to reach $6.81 billion by 2025, growing at a CAGR of 6.9%. This growth is driven by its applications in automotive, aerospace, and electronics.

In the automotive sector, aluminum die casting is used for engine blocks and transmission cases. These components benefit from aluminum's strength-to-weight ratio. According to experts, nearly 40% of automotive parts can be manufactured using die casting. This not only reduces vehicle weight but also improves fuel efficiency. However, the challenge lies in ensuring consistent quality across mass production.

The aerospace industry also utilizes aluminum die cast parts for turbine housings and structural components. These applications require precision and durability. Data indicates that aluminum die castings meet strict aerospace standards, yet achieving these standards can be difficult. Manufacturers often face issues with porosity and surface finish. Investing in better technology is crucial to overcoming these hurdles. The potential is vast, but it requires continual refinement and innovation.

Aluminum die casting is gaining attention for its environmental advantages. This process uses aluminum, a highly recyclable material. Recycling aluminum requires only 5% of the energy needed to produce new aluminum. This significant energy savings helps lower carbon emissions.

Moreover, aluminum die casting is efficient in material usage. Minimal waste occurs during production, which is critical in today’s manufacturing landscape. Yet, issues like the transportation footprint of raw materials remain a concern. Each step in the supply chain needs careful consideration to enhance sustainability.

While aluminum offers benefits, challenges persist. Not all recycling facilities are equally accessible. The journey from die casting to recycling can be complex. A deeper understanding of local capabilities is needed. Embracing aluminum die casting involves recognizing these hurdles. Small changes can lead to meaningful progress over time.

| Dimension | Weight (kg) | Recyclability (%) | Energy Consumption (kWh/kg) | Carbon Emissions (kg CO2/kg) |

|---|---|---|---|---|

| Small Part | 0.5 | 95 | 5 | 1.4 |

| Medium Part | 2.0 | 95 | 4.5 | 1.2 |

| Large Part | 5.0 | 95 | 4.0 | 1.0 |

| Custom Part | 3.0 | 95 | 4.3 | 1.3 |