+86-13516964051

+86-13516964051

The manufacturing industry is thriving with innovative solutions. One such solution is Die Casting Aluminum Parts. These parts are gaining popularity for their unique advantages. According to John Smith, a leading expert in this field, "Die Casting Aluminum Parts enhance productivity while reducing costs."

Die casting offers precise specifications and excellent surface finishes. This method allows for complex designs that traditional methods often struggle to achieve. However, not all manufacturers effectively utilize this technique. Some still rely on outdated practices, missing out on efficiency and quality.

The benefits of Die Casting Aluminum Parts extend beyond just manufacturing. They contribute to lightweight yet durable products. Industry leaders are adopting this technology, but challenges remain. Quality control must be emphasized, as inconsistencies can impact overall performance. Balancing innovation with traditional methods is crucial for success.

Die casting aluminum parts offer numerous advantages in manufacturing processes. The die casting technique can produce complex shapes with excellent dimensional accuracy. According to industry reports, aluminum die casting can achieve tolerances of up to ±0.5 mm. This precision is crucial for industries such as automotive, where parts must fit perfectly for safety and performance.

Another major benefit is the weight-to-strength ratio of aluminum. This material is lighter than steel but provides comparable strength. A study shows that using aluminum parts can reduce vehicle weight by approximately 30%. This reduction helps improve fuel efficiency, which is critical as industries strive to meet environmental regulations.

However, die casting is not without challenges. The initial tooling costs can be high, making it difficult for small manufacturers. Additionally, some defects, like porosity, may occur during the casting process. These imperfections could affect the performance of end products. Overall, while the advantages of aluminum die casting are significant, manufacturers must weigh the potential risks against the benefits.

Aluminum die casting offers remarkable design flexibility for various industries. The process allows for intricate shapes that create lighter and stronger parts. According to industry reports, 80% of manufacturers prefer aluminum die casting due to its ability to produce complex geometries without compromising structural integrity. This flexibility significantly impacts performance and cost-effectiveness.

Designers can integrate features like ribs and bosses directly into parts. This reduces assembly time and overall material waste. A report from the American Foundry Society states that aluminum die casting can lower production costs by 20% compared to traditional methods. Such savings are crucial in today's competitive market.

Despite these benefits, challenges exist. Some designs may still face limitations in wall thickness and surface finish. Designers must balance complexity and manufacturability carefully. Feedback from engineers and designers often reveals the need for iterative design adjustments. Embracing this process is vital for achieving optimal results in aluminum die casting projects.

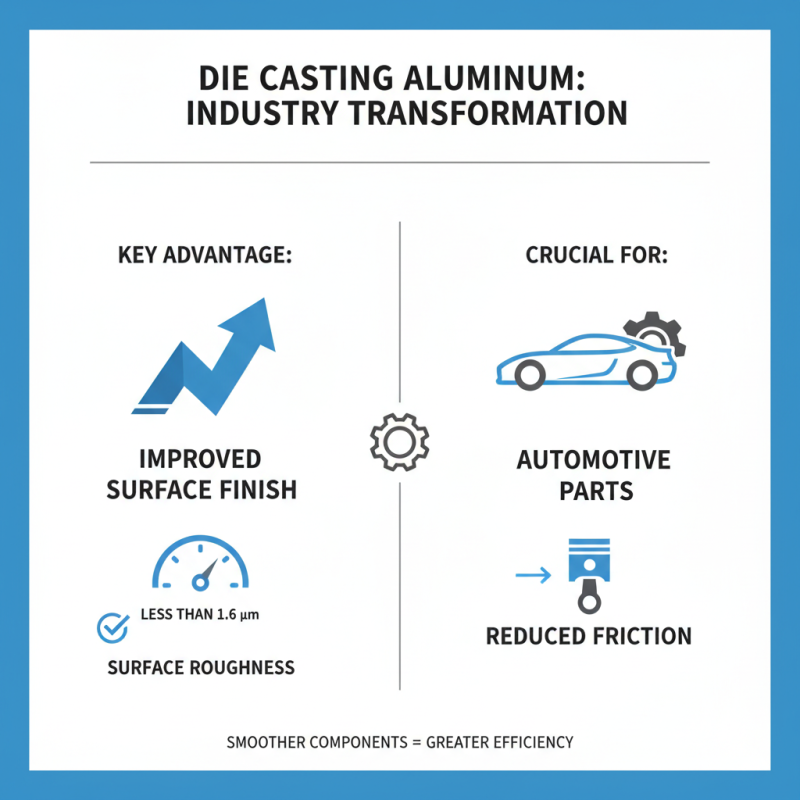

Die casting aluminum parts has transformed many industries. One key advantage is improved surface finish. Reports indicate that die-cast aluminum can achieve a surface roughness of less than 1.6 micrometers. This level of precision is crucial for components like automotive parts, which require smooth surfaces to reduce friction.

Precision in die-casting also impacts functionality. Customers often expect high-quality components with tight tolerances. In fact, studies show that die-cast parts can maintain tolerances of ±0.2 mm consistently. This level of accuracy is essential for manufacturers who rely on component interoperability. However, some challenges remain. Inconsistent mold design can lead to defects, resulting in parts that don’t meet expectations.

Another area of concern is the choice of aluminum alloys. Certain alloys provide better surface finishes than others. Yet, selecting the right alloy often requires testing. Many companies face challenges in predicting how various alloys will behave during the die-casting process. It's a reminder that while die casting offers remarkable benefits, a nuanced approach is necessary for optimal results.

Die casting aluminum parts offers significant cost-effectiveness for various industries. This manufacturing process ensures precision and speed. Moreover, it reduces the need for extensive machining after production. Lower labor costs contribute to an efficient workflow. Compared to other materials, aluminum is lightweight yet strong, making it an excellent choice.

The efficiency of die casting lies in its ability to create complex shapes in one go. This minimization of extra processes translates to savings on materials and time. Businesses benefit from quicker turnarounds. However, one must be aware of the initial investment for die casting equipment. It can be high, and not all companies may see the return they hoped for initially.

Quality control remains a challenge. Maintaining consistent specifications can be tough. Variability in raw materials can affect the final product. Companies must keep a close eye on production. While die cast aluminum offers compelling advantages, businesses should also reflect on their specific needs and capabilities. Investing in training and equipment is essential for maximizing these benefits.

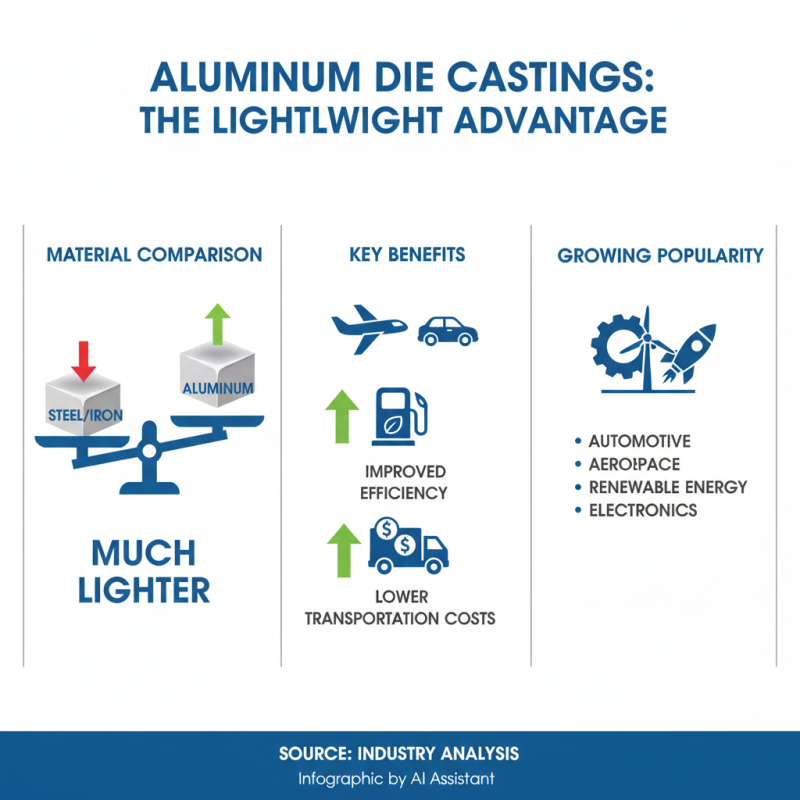

Aluminum die castings are increasingly popular in various industries. Their lightweight nature sets them apart. Aluminum parts are significantly lighter than steel or iron. This weight advantage leads to lower transportation costs and improved energy efficiency in applications like automotive and aerospace.

Moreover, aluminum die casting boasts impressive durability. The inherent properties of aluminum allow it to withstand harsh conditions, including temperature fluctuations and corrosion. Research indicates that aluminum has a fatigue strength that often exceeds that of traditional materials. However, the rigidity may not always match heavier metals. This trade-off often requires engineers to rethink design strategies to ensure reliability under stress.

In addition, the production of aluminum die cast parts can be more complex than anticipated. Factors like mold design and temperature control are critical. Poor design can lead to defects, impacting durability. Manufacturers must continuously adapt and refine processes. Balancing lightweight benefits with structural integrity is an ongoing challenge in the industry.