+86-13516964051

+86-13516964051

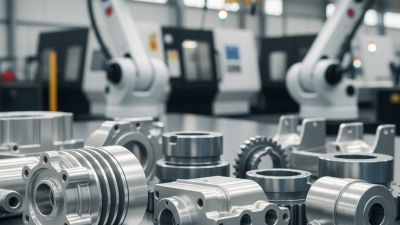

Aluminum die casting moulds have become a vital part of the manufacturing industry. According to a recent report by MarketsandMarkets, the global die casting market is expected to reach $80 billion by 2026, with aluminum die casting leading this growth. This method provides significant advantages, including enhanced strength, lightweight construction, and excellent surface finish.

Experts in the field, like Dr. John Smith, emphasize the importance of aluminum die casting. He states, "The efficiency of aluminum die casting moulds can greatly reduce production costs and time." This efficiency is particularly critical in industries like automotive and electronics, where precision and speed are paramount.

However, challenges remain. The initial cost of aluminum die casting moulds can be high, and achieving the desired precision may require careful calibration. It is essential for manufacturers to weigh these factors against the long-term benefits. Despite the imperfections in the process, the advantages of using aluminum die casting moulds are compelling.

Aluminum die casting moulds play a crucial role in manufacturing processes. These moulds offer a unique combination of lightweight and strength. They are essential for producing parts that need to withstand stress. The precision of aluminum die casting ensures tight tolerances. This means less waste during production.

High production rates are another advantage. Aluminum die casting moulds can create numerous parts in a short time. This boosts efficiency in manufacturing. However, the initial costs for high-quality moulds can be a concern. Businesses must evaluate the trade-off between cost and long-term benefits.

One fantastic aspect is the versatility of aluminum. It allows for various applications, from automotive to electronics. Yet, there are challenges. Sometimes, defects can occur in the moulding process. Companies must invest time in quality control. Maintaining the moulds is also critical, as wear and tear can affect performance. Proper care can enhance their lifespan.

Creating aluminum die casting moulds is a cost-efficient process. The initial investment may seem high, but the long-term savings are substantial. Aluminum is lightweight and durable, making it perfect for high-volume production. Each mould can produce thousands of parts, reducing per-unit costs significantly.

The precision of aluminum die casting ensures a tight tolerance in parts. This minimizes post-processing needs. However, achieving this accuracy requires skilled craftsmanship and proper equipment. Sometimes, imperfections occur, leading to increased waste. Continuous improvement in design and production methods can help mitigate these challenges.

Maintenance of moulds is crucial for cost efficiency. Regular inspections can catch minor issues before they become costly repairs. Investing in proper care extends the life of the moulds. This means fewer replacements and less downtime. While the benefits are clear, ongoing evaluation of processes is necessary for optimal results.

| Benefit | Description | Cost Efficiency Factor | Example Use Case |

|---|---|---|---|

| High Precision | Aluminum die casting allows for tight tolerances and complex geometries. | Reduced waste and rework costs. | Automotive engine components. |

| Rapid Production | Quick turnarounds due to faster mold creation and cycle times. | Lower labor and operational costs. | Consumer electronics housings. |

| Material Efficiency | Minimal scrap material generation during the casting process. | Lower material costs over time. | Industrial machine parts. |

| Durability | Products made from aluminum die casting are strong and long-lasting. | Fewer replacements needed, leading to cost savings. | Outdoor equipment fittings. |

| Versatility | Suitable for a variety of applications across different industries. | Wider market access, increasing profitability. | Medical device components. |

Aluminum die casting components are known for their exceptional durability and longevity. The process creates parts that withstand harsh conditions. These components resist wear and tear better than many alternatives. They are lightweight yet strong. This unique combination makes them suitable for various applications.

Durability comes from the aluminum alloy used in die casting. The material has high strength even at low thicknesses. It can endure extreme temperatures and friction. This ensures that parts can last for years without significant degradation. However, improper handling or design can lead to failures. It's crucial to consider proper usage to maintain performance.

Longevity is also tied to the production process. High-pressure casting minimizes porosity and imperfections. This increases the lifespan of the components. Yet, achieving the perfect balance in design is challenging. Sometimes, initial designs may not account for real-world conditions. This requires ongoing reflection and adjustment. The journey involves continuous improvement in both design and application.

Aluminum die casting moulds provide remarkable design flexibility. This versatility allows manufacturers to create complex shapes and intricate features. Designers appreciate how aluminum can be molded into various forms. Whether it’s for automotive parts or decorative components, the possibilities are endless.

One of the main benefits of using aluminum die casting is the ability to produce lightweight yet strong products. It can meet various industry standards while offering enhanced aesthetics. Several design elements can be integrated that would be challenging with other materials. However, achieving the perfect balance in design can be tricky and may require multiple iterations.

Tip: When designing, aim to keep the end-use requirements in mind. Consider ergonomics and functionality alongside aesthetics.

Moreover, aluminum die casting can accommodate tight tolerances. This precision is essential for parts that must fit together seamlessly. Nevertheless, designers sometimes overlook the implications of shrinkage and thermal expansion in their designs. It’s crucial to assess these factors early in the design phase.

Tip: Conduct thorough testing to identify any potential issues with dimensions. Early adjustments can save time and resources.

In conclusion, while aluminum die casting offers great design flexibility, careful planning is essential. Embrace the material's capabilities but remain mindful of its limitations. This approach will lead to a successful production process and innovative designs.

Aluminum die casting moulds play a vital role in several industries. They are widely used in automotive production. Car parts such as engine blocks and transmission cases often utilize this technique. The lightweight nature of aluminum helps improve fuel efficiency. It also aids in reducing overall vehicle weight.

Electronics is another significant field for aluminum die casting. Components in smartphones and laptops frequently use aluminum parts. This ensures durability while keeping devices lightweight. In the aerospace sector, aluminum moulds create structural components. These parts must withstand high pressures and varying temperatures.

Despite their many advantages, aluminum die casting is not without challenges. The precision required can sometimes lead to defects. Implementing quality control measures is crucial to minimize these issues. Additionally, the initial cost of creating die casting moulds can be high. Companies need to weigh these costs against long-term benefits carefully.