+86-13516964051

+86-13516964051

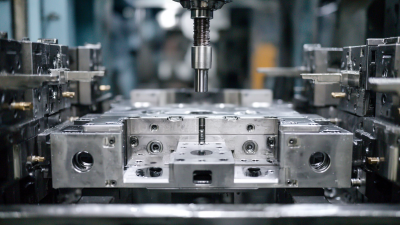

Metal Die Casting has revolutionized modern manufacturing. This process offers various advantages that enhance product quality and production efficiency. The method involves pouring molten metal into a pre-shaped mold, setting the stage for exceptional precision.

Manufacturers appreciate Metal Die Casting for its speed and detail. The process allows complex shapes and fine features to be produced swiftly. However, not every design is ideal for die casting. Sometimes, intricate designs can become costly. Yet, when executed well, this method results in strong, lightweight components.

The energy efficiency of Metal Die Casting is noteworthy. It consumes less energy compared to traditional methods. However, there are drawbacks to consider, such as tooling costs. Companies must weigh these factors carefully. Overall, the potential of Metal Die Casting in manufacturing is immense, though it invites reflection on practical application and strategic planning.

Metal die casting stands out in modern manufacturing due to its high precision and intricate detail. This technique allows manufacturers to produce components with exceptional accuracy. Parts can be created with tight tolerances, often within a few thousandths of an inch. Such precision is crucial for industries like automotive and aerospace, where performance and reliability are essential.

The detail achieved in metal die casting is remarkable. Complex shapes and fine features are easily replicated. For instance, intricate designs and small engravings can be formed without losing quality. However, achieving such detail requires skilled operators and advanced machinery. There can be challenges, especially when handling certain metals. Inconsistent metal flow or temperature can affect the final quality.

Moreover, while die casting can significantly reduce the need for additional machining, it does not eliminate it entirely. Some components may still require adjustments after casting. This highlights the importance of careful planning and design. Every step in the process matters. Balancing precision with practical applications is important for optimal results.

Metal die casting is revolutionizing modern manufacturing. One of its significant advantages is the reduction of production costs. Efficient metal die casting techniques allow manufacturers to produce high-quality parts at lower prices. A study by the American Foundry Society found that die casting can reduce production costs by up to 30% compared to traditional methods.

This efficiency comes from various factors. High-speed production makes die casting faster. It reduces the number of processes required to create complex shapes. Moreover, the scrap rate is lower, meaning less wasted material. The Aluminum Association reported that die casting can achieve a scrap rate of only 2%. This statistic highlights the technique's effectiveness in resource management.

However, challenges exist. Initial setup costs can be high. Designing dies requires investment and time. Manufacturers must balance these upfront costs with long-term savings. It’s crucial to evaluate the breakeven point for various projects. Fine-tuning the die casting process can lead to significant improvements. Addressing these issues effectively can maximize benefits, making die casting a compelling choice for modern manufacturers.

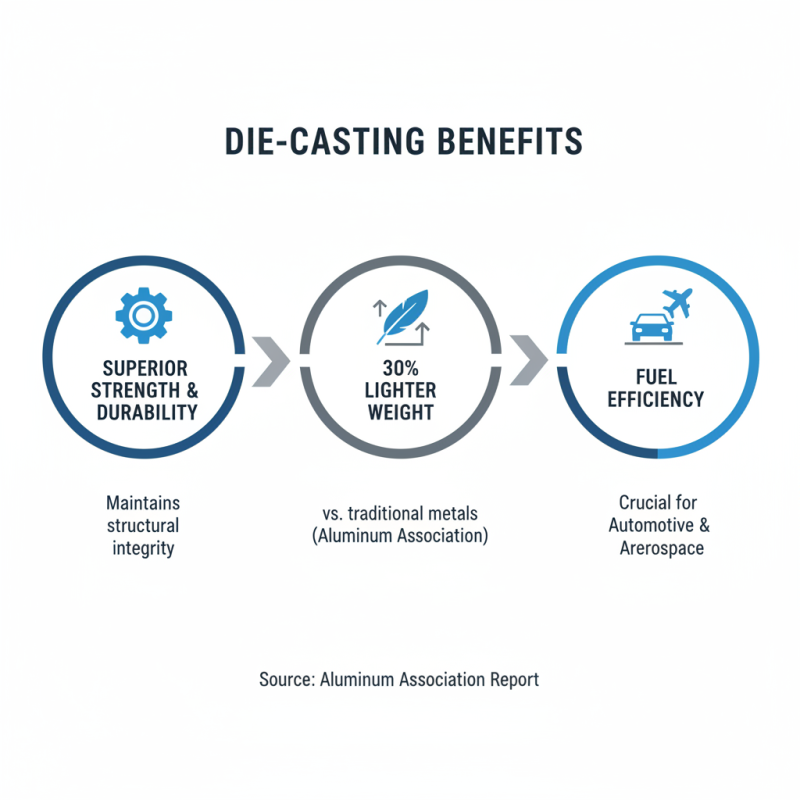

Die-casting offers remarkable strength and durability in manufacturing. According to a report from the Aluminum Association, die-cast aluminum parts can be 30% lighter than traditional metal parts while maintaining their structural integrity. This is crucial in industries such as automotive and aerospace, where weight reduction directly impacts fuel efficiency.

The process also ensures precise dimensions, minimizing material waste. Studies show that die-cast components possess outstanding tensile strength, often exceeding 200 MPa. This durability means the parts can withstand extreme conditions, reducing the risk of failure in critical applications. However, the initial tooling costs can be high. Companies often hesitate to invest upfront.

In high-volume productions, the longevity of die-cast molds is impressive. They can produce thousands of parts with consistent quality. Yet, companies must reflect on the necessity of high upfront investment versus long-term savings. The balance between cost and quality should guide decision-making. The benefits are clear, but careful analysis is crucial for sustainable success in modern manufacturing.

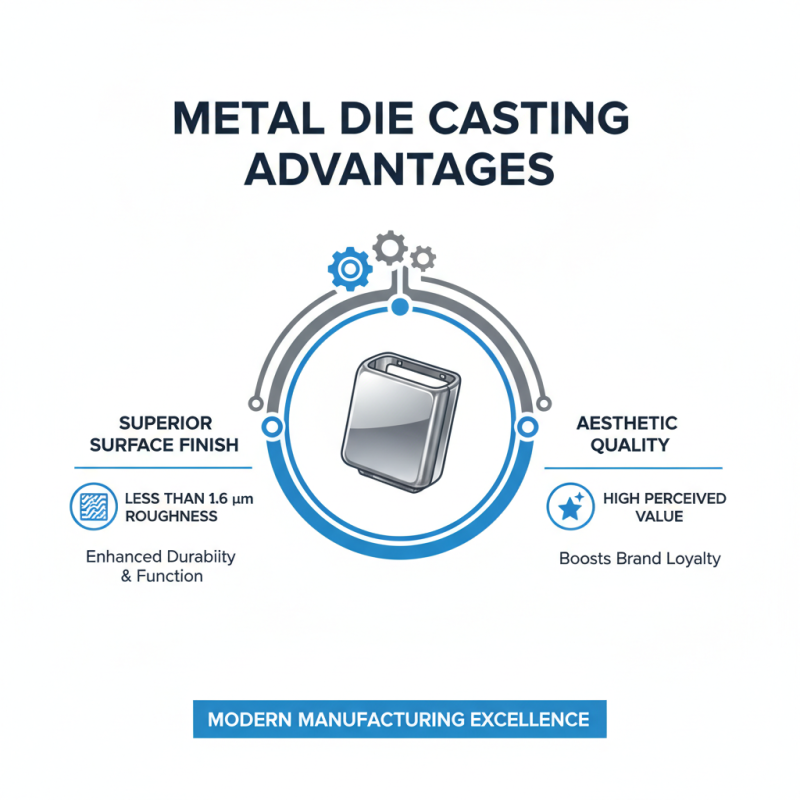

Metal die casting offers significant advantages in modern manufacturing, particularly regarding surface finish and aesthetic quality. According to industry reports, a well-executed die casting can achieve a surface roughness of less than 1.6 microns. This precision allows for products that not only function well but look appealing too. With a smooth surface finish, users often perceive the quality of the product to be higher. It can enhance customer satisfaction and strengthen brand loyalty.

However, achieving this quality is not without challenges. Factors like mold design and die material can affect surface quality. Additionally, imperfections may arise during the casting process, such as air traps or incomplete filling. Continuous monitoring and adjustment are essential to mitigate these issues. Manufacturers must remain vigilant, as inconsistent quality can lead to increased costs. The focus on aesthetic appeal should not overshadow the importance of functionality in final products. Striking the right balance is crucial for overall success in die casting applications.

Metal die casting offers significant advantages in modern manufacturing, particularly in design flexibility and complexity. According to a 2021 industry report, nearly 70% of manufacturers have adopted metal die casting due to its efficiency in creating intricate shapes. This process allows for the production of complex geometries that traditional manufacturing methods struggle to achieve.

Design flexibility is a pivotal factor. Manufacturers can quickly produce prototypes with varying shapes and sizes. A 2020 study highlighted that companies experienced a 30% reduction in design time when using die casting. This method enables engineers to experiment with various designs without incurring high costs. However, challenges remain; achieving precise tolerances can be difficult.

The ability to create lightweight yet durable components is another advantage. Metal die casting often results in parts that are 30% lighter than those made with other methods. This weight reduction is crucial for industries like automotive and aerospace, which prioritize efficiency. Nevertheless, the initial investment in die casting equipment can be substantial, posing a barrier for smaller manufacturers.

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Design Flexibility | Allows for complex shapes and detailed features in designs. | Enables innovative product development. |

| Material Efficiency | Minimizes waste material during production. | Reduces costs and environmental impact. |

| High Precision | Produces parts with tight tolerances. | Enhances the quality of assembled products. |

| Rapid Production | High-speed manufacturing processes. | Improves time-to-market for products. |

| Durability | Creates strong and long-lasting components. | Enhances product lifespan and reliability. |

| Surface Finish | Achieves a fine surface finish without additional processes. | Reduces post-processing requirements. |

| Cost Effectiveness | Lower per-unit costs on large production runs. | Boosts competitiveness in pricing. |

| Enhanced Safety | Reduces potential hazards associated with other manufacturing techniques. | Fosters safer work environments. |

| Consistent Quality | Produces uniform parts with repeatable quality. | Maintains brand reputation for quality. |

| Customization | Facilitates adaptations and variations of products. | Meets specific customer requirements efficiently. |