+86-13516964051

+86-13516964051

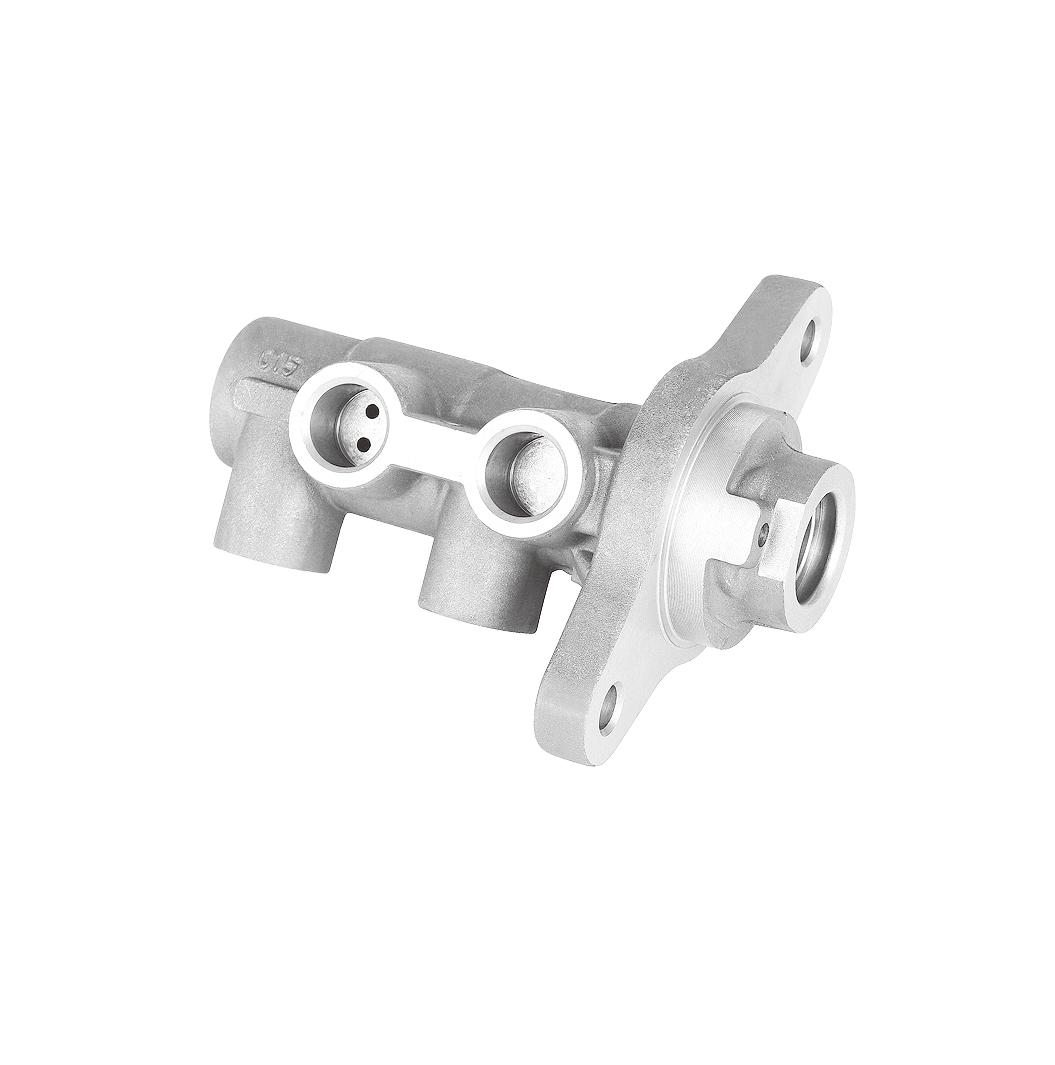

Application of Aluminum Alloy Low Pressure Casting in Automobiles and Trucks

description1

Engine parts

Cylinder block: As one of the core components of the engine, the quality and performance of the engine cylinder block are directly related to the stability and durability of the engine. The cylinder block produced by aluminum alloy low-pressure casting process has the characteristics of light weight, good heat dissipation performance, high strength and high dimensional accuracy. The lightweight design helps to reduce the overall weight of the car, thereby improving fuel economy and reducing exhaust emissions. At the same time, good heat dissipation performance ensures that the engine maintains a stable temperature state when running at high load, extending the service life of the engine. Its high-precision size and good strength can ensure the precise matching between the engine components, improving the engine's working efficiency and power output.

Intake manifold: Aluminum alloy low-pressure casting intake manifold can realize complex internal flow channel design, optimize intake efficiency, and make air and fuel mix more evenly, thereby improving the engine's power performance and combustion efficiency. In addition, compared with traditional metal materials, the intake manifold made of aluminum alloy is greatly reduced in weight, effectively reducing the burden on the front-end accessories of the engine, and helping to improve the vehicle's handling performance and acceleration performance.

Chassis components

Wheels: Aluminum alloy low-pressure casting wheels play a key role in the chassis system of the car. Compared with traditional steel wheels, aluminum alloy wheels are lighter, which can effectively reduce the unsprung mass of the vehicle, improve the vehicle's handling stability and driving comfort. At the same time, the good heat dissipation performance of aluminum alloy materials helps to dissipate heat from the braking system, improve braking effect and safety. The optimized aluminum alloy wheels can also fully meet the various working conditions requirements during vehicle driving in terms of strength and stiffness, ensuring the reliability and safety of vehicle driving. Its beautiful appearance can also improve the overall styling quality of the vehicle.

Steering knuckle: As an important component connecting the wheel hub and the suspension system, the aluminum alloy low-pressure casting steering knuckle can not only achieve lightweight, reduce the inertia of the vehicle steering system, and improve the steering response speed and accuracy, but also ensure sufficient strength. Under the premise of ensuring reliability and durability during vehicle driving, through advanced casting technology and material processing technology, ensure driving safety.

Body structure components

Engine bracket: The aluminum alloy low-pressure casting engine bracket is used to support and fix the engine. Its lightweight characteristics help to reduce the weight of the front of the vehicle, optimize the front and rear weight ratio of the vehicle, and improve the driving stability of the vehicle. At the same time, the specially designed structure and precise casting process can ensure that the engine bracket maintains a stable and reliable working state when it is subjected to vibration and torque during engine operation, prolong the service life of the connection between the engine and the body, and reduce maintenance costs.

Cross and longitudinal beams: The application of aluminum alloy low-pressure casting cross and longitudinal beams in the automobile body frame can achieve lightweight design of the body while ensuring the overall structural strength and rigidity of the body. This not only helps to improve the fuel economy of the vehicle, but also effectively absorbs and disperses the impact energy through reasonable energy absorption design when the vehicle collides, protects the safety of the occupants in the car, and improves the safety performance level of the vehicle.

Carriage parts

Carriage floor cross beams: The floor cross beams of truck compartments need to withstand large loads and frequent impact forces. With its good strength and toughness, aluminum alloy low-pressure casting cross beams can meet the use requirements of the compartment floor under heavy load conditions. Compared with steel cross beams, its weight is significantly reduced, which effectively reduces the overall mass of the truck, thereby improving the truck's load capacity, increasing cargo transportation efficiency, and reducing transportation costs. At the same time, aluminum alloy materials have good corrosion resistance. In harsh transportation environments, they can extend the service life of the floor beams of the carriage and reduce maintenance and replacement costs.

Carriage side panel columns: Aluminum alloy low-pressure casting carriage side panel columns provide good structural support for the carriage, ensuring the overall strength and rigidity of the carriage. Its lightweight advantage enables the truck to reduce the burden of its own weight on the road load when loading the same cargo, which helps to reduce fuel consumption and exhaust emissions during transportation and meet environmental protection requirements. In addition, the surface-treated aluminum alloy columns have good appearance quality, which can improve the overall aesthetics of the truck compartment and enhance the market competitiveness of the product.

Cabin components

Instrument panel bracket: Aluminum alloy low-pressure casting instrument panel bracket plays a key supporting role in the truck cab. Its precise size and good strength can ensure the close fit between the instrument panel and the interior of the cab, providing the driver with a stable and reliable operating platform. At the same time, the lightweight design helps to reduce the weight of the cab, thereby improving the power performance and fuel economy of the truck and reducing operating costs. During the driving process of the vehicle, the dashboard bracket made of aluminum alloy can also effectively resist vibration and impact, ensuring the normal operation and service life of the dashboard.

Seat bracket: The seat in the truck cab needs to bear the weight of the driver as well as the bumps and vibrations during driving. The aluminum alloy low-pressure casting seat bracket, with its high strength and good elasticity, can provide reliable support and buffering to ensure the driver's riding comfort and safety. Compared with traditional materials, the lightweight advantage of aluminum alloy seat bracket helps to reduce the weight inside the cab, indirectly improve the truck's cargo capacity and increase economic benefits. In addition, it has good corrosion resistance and wear resistance, and can maintain good performance in complex transportation environments and long-term use, reducing maintenance frequency.

Transmission system components

Transmission housing: The aluminum alloy low-pressure casting transmission housing plays an important role in the truck transmission system. It not only provides good protection and support for the gears and other components inside the transmission, but its lightweight characteristics also help to reduce the rotational inertia of the transmission, improve the gear shifting smoothness and transmission efficiency of the transmission, and thus improve the power transmission performance of the truck. At the same time, aluminum alloy materials have good heat dissipation performance, which is conducive to timely heat dissipation of the transmission during high-speed operation, ensuring the normal operating temperature range of the transmission oil, extending the service life of the transmission, and reducing maintenance costs.

Differential housing: The truck differential housing is produced using aluminum alloy low-pressure casting technology, which can achieve lightweight design of the housing while ensuring sufficient strength and rigidity to withstand the torque and load during vehicle driving. This helps to reduce the weight of the vehicle's rear axle, improve the front and rear axle load distribution of the vehicle, and improve the vehicle's handling stability and driving performance. In addition, good heat dissipation performance can ensure that the operating temperature of the internal gears of the differential is stable during high-load operation, reduce gear wear, ensure the reliability and durability of the differential, and ensure the driving safety and power transmission stability of the truck under various complex road conditions.

01

Overview of aluminum alloy low-pressure casting technology

Aluminum alloy low-pressure casting is an advanced casting process between gravity casting and high-pressure casting. It presses the liquid aluminum alloy into the mold cavity at a relatively low pressure, so that the metal liquid can fully fill the mold to form a casting with complex shape, precise size and excellent performance. Compared with traditional gravity casting, low-pressure casting can effectively reduce defects such as pores and shrinkage inside the casting, and improve the density and mechanical properties of the casting; compared with high-pressure casting, low-pressure casting has relatively low equipment requirements due to its low pressure, and can reduce stress concentration inside the casting, avoiding problems such as cold shut and cracks caused by excessive filling pressure. Therefore, it has unique advantages in the production of large, thin-walled and complex aluminum alloy parts.

02

Our professional manufacturing capabilities and quality assurance system

Advanced equipment and process flow

We are equipped with internationally leading aluminum alloy low-pressure casting equipment, including high-precision melting furnaces, advanced low-pressure casting machines, and highly automated mold temperature control systems. The precise coordination of these equipment ensures the smelting quality of aluminum alloy liquid, the stability of the filling process and the cooling rate control of the casting, so as to produce high-quality and stable aluminum alloy castings. During the casting process, we strictly follow the optimized process parameters, such as pouring temperature, pressure increase speed, pressure holding time, etc., and make precise adjustments according to the structure and performance requirements of different castings to ensure that each casting can achieve the best molding effect and mechanical properties.

Professional heat treatment technology

Heat treatment is a key link in improving the performance of aluminum alloy castings. We have an experienced heat treatment team that is proficient in a variety of aluminum alloy heat treatment processes, including solution treatment, aging treatment and quenching. By accurately controlling the heat treatment temperature and time of the casting, the comprehensive properties of the casting, such as hardness, strength, toughness and corrosion resistance, can be significantly improved. For example, the strength of aluminum alloy castings that have been properly heat treated can be increased by 20% - 30%, while maintaining good plasticity, meeting the use requirements of automobile and truck parts under complex working conditions. In addition, we can also customize special heat treatment processes according to the needs of different customers to meet the performance indicators of specific parts.

Hard anodizing treatment of aluminum alloy surface

In order to further enhance the surface hardness, wear resistance and corrosion resistance of aluminum alloy castings, we provide professional hard anodizing treatment services for aluminum alloy surfaces. The hard anodizing process can form a dense, uniform and thickness-controlled oxide film on the surface of aluminum alloy, and its hardness can reach HV300-600 or above, which significantly improves the wear resistance and scratch resistance of castings. At the same time, the surface of aluminum alloy after hard anodizing has good corrosion resistance, which can effectively resist the erosion of media such as acid, alkali, salt spray, etc. in harsh working environment, and extend the service life of castings. Our surface treatment workshop is equipped with complete environmental protection facilities to ensure that the treatment process meets strict environmental protection standards and provide customers with environmentally friendly and high-quality surface treatment solutions.

Strict quality inspection system

We have established a complete quality inspection system, and strict quality control is carried out in every link from the procurement of raw materials to the delivery of finished castings. In terms of raw material procurement, we have established long-term and stable cooperative relations with many high-quality aluminum alloy raw material suppliers to ensure that the quality and performance of raw materials meet national standards and industry specifications. During the casting production process, we set up multiple quality inspection procedures, including size inspection, appearance inspection, non-destructive testing (such as ultrasonic testing, X-ray testing, etc.) and mechanical property testing. The professional quality inspection team uses advanced testing equipment to accurately test and evaluate the various indicators of castings to ensure that every casting delivered to customers meets the specified quality standards and customer technical requirements. Once a quality problem is found, we will immediately start the quality problem traceability and improvement mechanism, analyze the cause and take effective corrective measures to prevent similar problems from happening again and ensure the continuous stability and improvement of product quality.