+86-13516964051

+86-13516964051 Custom Aluminum Gravity Die Casting Solutions from Trusted OEM Factory Suppliers

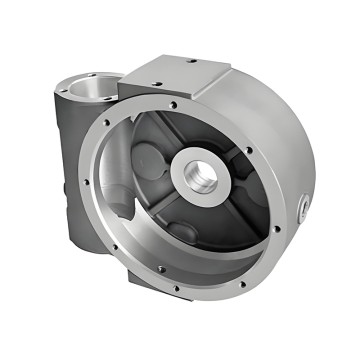

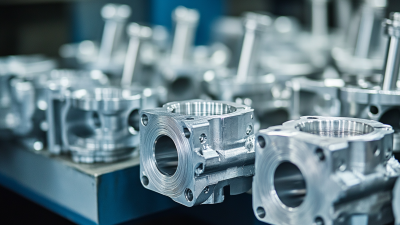

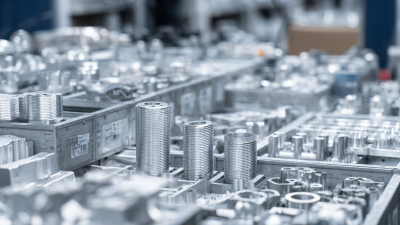

At Yongkang Hantai Industry And Trade Co., Ltd., we specialize in tailored ODM solutions for Aluminum Gravity Die Casting. Our commitment to delivering high-quality, precise, and durable components is backed by our advanced facilities and dedicated team. Whether you operate in automotive, aerospace, or another industry, we provide premium casting services designed to enhance your manufacturing processes. Partnering with us guarantees competitive pricing and a seamless experience throughout your project. Let’s collaborate to turn your ideas into reality.10 tips Aluminum Gravity Die Casting Sets the Industry Standard Winning in 2025

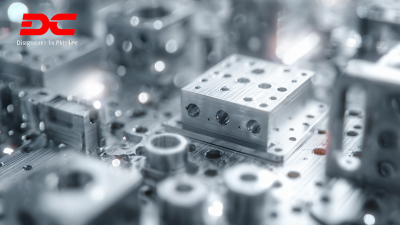

In the dynamic landscape of the automotive industry, staying ahead requires not only innovation but also a commitment to quality. Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, has been a trailblazer in aluminum gravity die casting, setting the industry standard through relentless technological advancements and quality enhancement. As we approach 2025, here are ten essential tips that exemplify how aluminum gravity die casting can help your business thrive. First and foremost, investing in state-of-the-art technology is crucial. By embracing cutting-edge manufacturing processes, you can enhance efficiency and ensure precision in every component produced. Furthermore, prioritizing sustainable practices in your die Casting Operations not only meets the growing demand for eco-friendly products but also strengthens your market position. Collaborating closely with suppliers and customers leads to synergies that drive innovation while streamlining the supply chain. Additionally, focus on rigorous quality control measures to meet and exceed international standards. This will not only bolster customer satisfaction but also elevate your brand reputation globally. As the automotive sector evolves, staying informed on industry trends, regulations, and customer preferences is vital for anticipating market shifts and adjusting your strategies accordingly. At Yongkang Hantai, our commitment to these principles empowers us to provide high-quality parts and components that meet the evolving needs of global clients in the automotive domain. By adhering to these ten tips, your business can not only survive but thrive in the competitive landscape of 2025 and beyond.

10 Tips Aluminum Gravity Die Casting Sets the Industry Standard Winning in 2025

| Tip Number | Tip Description | Expected Impact (2025) | Implementation Difficulty |

|---|---|---|---|

| 1 | Optimize mold design for heat distribution | Reduced cooling times by 15% | Medium |

| 2 | Use advanced aluminum alloys | Improved strength-to-weight ratio | High |

| 3 | Implement real-time quality control | Decrease defect rates by 20% | Medium |

| 4 | Enhance automation in die casting process | Increase production efficiency by 25% | High |

| 5 | Train workforce on new technologies | Improved operator efficiency | Medium |

| 6 | Utilize simulation software for process planning | Optimized resource allocation | Low |

| 7 | Focus on waste reduction techniques | Decrease material waste by 30% | Medium |

| 8 | Enhance surface finish through better techniques | Higher customer satisfaction | Medium |

| 9 | Explore eco-friendly materials and processes | Reduced environmental impact | High |

| 10 | Invest in predictive maintenance technologies | Minimized downtime | High |

Step-by-Step Guide Aluminum Gravity Die Casting Guarantees Peak Performance Your Trusted OEM Partner

J

Jackson Allen

The item exceeded all my expectations in quality. The support team was professional, friendly, and incredibly helpful throughout the process.

21 June 2025

A

Aria Cooper

What a fantastic purchase! The quality is unmatched, and the after-sale service was exemplary with professional support.

16 May 2025

A

Anthony Baker

This product is outstanding! The customer service team was professional and helped me with all my inquiries.

10 May 2025

H

Hannah Turner

Absolutely love this product! The support team demonstrated high expertise and effectively addressed all my questions.

05 June 2025

S

Sebastian Carter

High-quality construction and materials! The customer service was incredibly responsive and professional.

29 May 2025

E

Elias Young

Incredible quality craftsmanship! The customer service team was knowledgeable and made the process a breeze.

25 June 2025