+86-13516964051

+86-13516964051

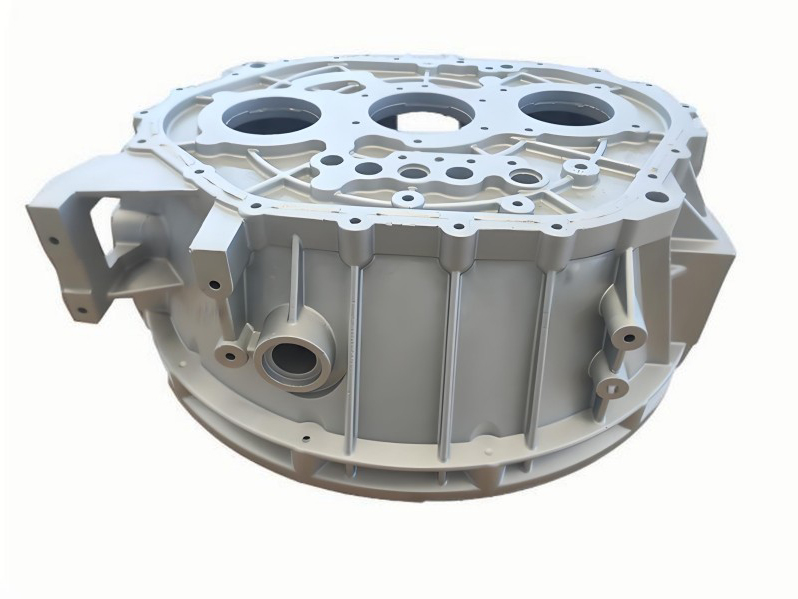

Aluminum alloy low-pressure casting: professional manufacturing and processing services

description1

Process Overview

Aluminum alloy low-pressure casting is an advanced metal forming process. Its principle is to inject liquid aluminum alloy into the mold cavity at a lower pressure, so that the molten metal can smoothly fill the mold under pressure until it solidifies and forms. Compared with traditional casting processes, low-pressure casting has many significant advantages, such as effectively reducing the turbulence and oxidation of the molten metal during the filling process, thereby reducing the probability of internal defects such as pores and inclusions in the casting, and improving the density and mechanical properties of the casting. At the same time, low-pressure casting can achieve precise control of the pouring speed and pressure of the molten metal, which makes the aluminum alloy castings produced have higher dimensional accuracy and lower surface roughness, and can meet the manufacturing requirements of complex shapes and precision parts. It is widely used in multiple industries such as automotive parts, aerospace, mechanical equipment, and electronic and electrical housings, providing reliable technical support for the lightweight and high-performance of products.

Equipment and technical advantages

Advanced casting equipment: Our company is equipped with a series of internationally leading aluminum alloy low-pressure casting equipment, which are highly automated and intelligent. From mold preheating, metal melting, pouring pressure and speed control to cooling and removal of castings, the entire process can be controlled stably and efficiently through precise program control.

Precision mold manufacturing technology: High-quality castings are inseparable from precision molds. We have a professional mold design and manufacturing team, using advanced CAD/CAM software for 3D modeling and structural optimization design of molds, taking into full account factors such as shrinkage rate, demoulding slope, and gating system design of castings to ensure the accuracy and durability of molds.

Melting and quality control technology: In the aluminum alloy smelting process, we use advanced melting furnace equipment and precise temperature control system to ensure that the molten metal is melted and insulated at a suitable temperature to avoid problems such as metal component segregation and oxidation burning caused by temperature fluctuations.

Surface treatment and post-processing

Aluminum alloy surface hard oxidation treatment: Our company specializes in aluminum alloy surface hard oxidation processing services. Hard oxidation is a surface treatment technology that generates a dense, thick and high-hardness oxide film on the surface of aluminum alloy through electrolysis. After hard oxidation treatment, the surface hardness of aluminum alloy castings can be greatly improved to [specific hardness value range], which significantly enhances the wear resistance, corrosion resistance and fatigue resistance of the castings.

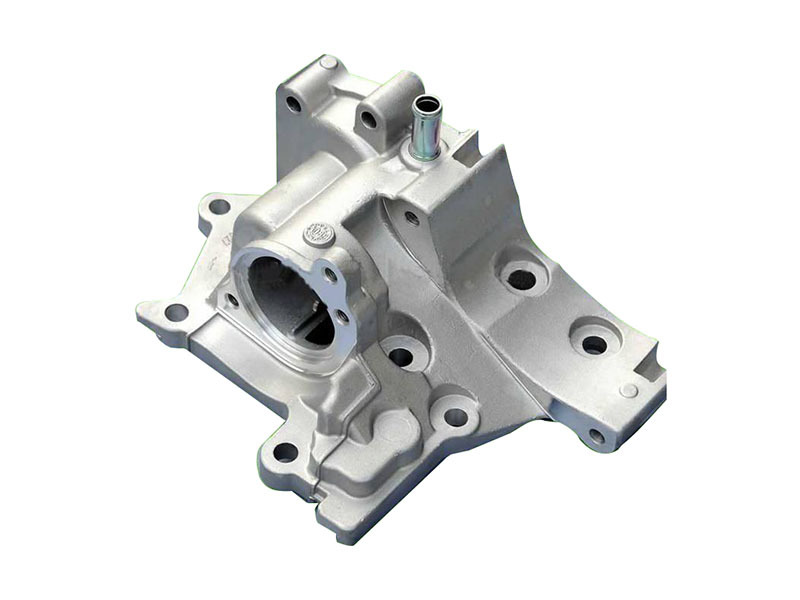

Metalworking services: We provide comprehensive aluminum alloy casting metalworking services, including turning, milling, drilling, tapping, grinding and other processing technologies. With high-precision metalworking equipment and experienced processing technicians, we can perform high-precision dimensional trimming and secondary processing of complex shapes on aluminum alloy low-pressure castings, so that the castings can achieve higher assembly accuracy and functional requirements.

Application fields and customer customization services

Wide application fields: Our aluminum alloy low-pressure casting products are widely used in many industries. In the automotive industry, we provide casting and processing services for key parts such as engine blocks, cylinder heads, intake manifolds, brake components, etc., to help the lightweight and high-performance development of automobiles.

Customer customization service: We are well aware that the needs of each customer are unique, so we are committed to providing customers with personalized customization services. From the design stage of the product, our technical team has worked closely with customers to provide customers with professional process consultation and design optimization suggestions based on product usage requirements, functional characteristics, production batches and other factors. During the production process, we strictly arrange production plans according to customer order requirements to ensure that products are delivered on time.

Quality assurance and after-sales service

Strict quality assurance system: Our company has established a complete quality management system, covering all aspects such as raw material procurement, production process control, product inspection and testing. Starting from the inspection of raw materials entering the factory, we conduct strict quality inspections on each batch of raw materials to ensure that they meet national standards and industry standards.

Perfect after-sales service: We provide customers with comprehensive after-sales service. After the product is delivered, our technical team will communicate with customers in a timely manner to understand the use of the product and answer any questions encountered by customers during use.

01

FAQ

Q1: What is the biggest difference between low-pressure casting and high-pressure casting of aluminum alloys?

Answer: The main difference between low-pressure casting and high-pressure casting of aluminum alloys lies in the filling method and pressure of the molten metal. Low-pressure casting is to make the molten metal rise steadily to fill the mold cavity under relatively low pressure (generally in [specific low pressure range]). This method can effectively reduce the turbulence and oxidation of the molten metal, and the casting has fewer internal defects, high surface quality and high dimensional accuracy; while high-pressure casting is to quickly press the metal into the mold cavity under high pressure (usually in [specific high pressure range]). Although the production efficiency is high, the molten metal is prone to turbulence, air entrainment and oxidation inclusions during high-speed filling, resulting in relatively more defects such as pores and looseness in the casting, which has a certain impact on the mechanical properties and quality stability of the casting.

Q2: Will the hard oxidation treatment of the aluminum alloy surface affect the mechanical properties of the casting?

Answer: If the process of hard oxidation treatment of the aluminum alloy surface is properly controlled, it will have little effect on the mechanical properties of the casting, but will improve its performance to a certain extent. Hard oxidation treatment mainly forms a dense oxide film on the surface of the casting. This oxide film has a high hardness and can enhance the wear resistance and fatigue resistance of the casting surface. At the same time, because the oxide film is closely combined with the base metal, it will not significantly change the overall mechanical properties of the casting, such as tensile strength and yield strength. However, in some special cases, such as excessively thick oxide film or improper processing parameters, it may have a slight adverse effect on the mechanical properties of the casting, such as ductility, but generally within a reasonable process range, this effect can be ignored, and the surface performance improvement advantage it brings is more significant.

Q3: Can aluminum alloy low-pressure castings be welded?

Answer: In general, aluminum alloy low-pressure castings can be welded, but the selection of welding process and materials needs to be determined according to the specific aluminum alloy composition and the use requirements of the casting. Common aluminum alloy welding methods include tungsten inert gas arc welding (TIG), metal inert gas arc welding (MIG), etc. Due to the good thermal conductivity of aluminum alloy, a high heat input is required during welding, and attention should be paid to the control of welding parameters, such as welding current, voltage, welding speed, etc., to avoid welding defects such as pores and cracks. At the same time, the composition of the welding material (welding wire) should match the casting base material to ensure the strength and performance of the welded joint. However, in some special application scenarios with extremely high requirements for welding performance, the chemical composition and microstructure of aluminum alloy castings may need to be specially designed and optimized to improve their welding performance.

Q4: What is the minimum production batch of aluminum alloy low-pressure casting?

A: The minimum production batch of our aluminum alloy low-pressure casting is flexible to meet the diverse needs of customers. For new customers or small batch trial orders, we can usually accept a production batch of [specific minimum batch value], which enables some customers who are engaged in new product development, sample production, small-scale market testing, etc. to easily obtain the required aluminum alloy low-pressure casting products. For large-scale production orders for long-term cooperation, we have efficient production capacity and large-scale production capacity, which can ensure that order tasks are completed on time, according to quality and quantity, and provide customers with a stable supply of products.

Q5: How to ensure the reliability of aluminum alloy low-pressure castings in complex use environments?

A: To ensure the reliability of aluminum alloy low-pressure castings in complex use environments, we take measures from multiple aspects. First, in the product design stage, we fully consider the use environment requirements of castings (such as temperature, humidity, corrosive media, mechanical load, etc.), and improve the stress corrosion resistance and fatigue performance of castings by optimizing the structural design and wall thickness design of castings. Secondly, in the selection of raw materials, strictly select aluminum alloy grades that meet the requirements of specific working conditions to ensure that the material itself has good environmental resistance. In terms of production process control, the casting parameters, heat treatment process parameters and surface treatment process parameters are precisely controlled to optimize the microstructure and surface properties of the castings so that they can adapt to the test of complex environments. Finally, through strict quality inspection methods, various performance indicators of castings are tested and verified, including accelerated life tests in simulated use environments. Only castings that have been fully evaluated and meet the reliability requirements will be delivered to customers for use, thereby ensuring the reliability and stability of castings in actual complex use environments.