+86-13516964051

+86-13516964051 Expert Factory Solutions for Aluminium Sand Casting OEM Services

At Yongkang Hantai Industry And Trade Co., Ltd., we pride ourselves on our exceptional Aluminium Sand Casting services that combine superior craftsmanship with unparalleled customer support. Each product we create is built to meet stringent quality standards, ensuring reliability for all your industrial applications. Our meticulous attention to detail ensures that only the finest materials are utilized throughout the casting process. With a dedicated team ready to assist you, we ensure a smooth purchasing experience that prioritizes your needs. Trust us for your Aluminium Sand Casting projects and enjoy the outstanding quality and service that sets us apart.Step-by-Step Guide Aluminium Sand Casting Is The Best Products

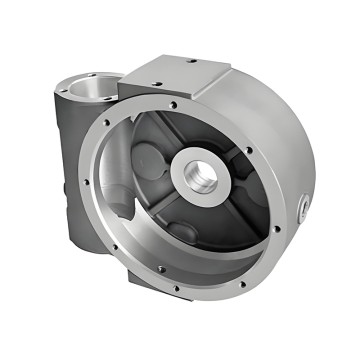

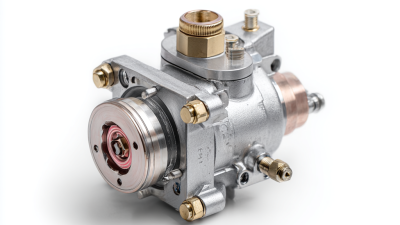

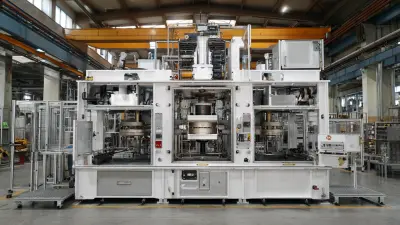

Aluminium sand casting has emerged as a premier choice for manufacturers looking to produce high-quality parts with exceptional durability and precision. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we have harnessed technological innovation and stringent quality control to position ourselves as a key supplier in the automotive industry. Our commitment to excellence allows us to deliver superior aluminium castings that meet the demanding requirements of global procurement partners. The step-by-step process of aluminium sand casting ensures that every component is crafted with meticulous attention to detail. Initially, a pattern is created and placed in a mold made of sand, which is then compacted to form a cavity that mirrors the desired shape. Once the mold is prepared, molten aluminium is poured in, filling the cavity to create robust parts. The final step involves cooling and finishing, yielding components that are not only lightweight but also exceptionally resistant to corrosion and wear. This makes our castings ideal for automotive applications, where reliability and performance are paramount. By choosing Yongkang Hantai as your supplier, you benefit from our decades of experience and unwavering commitment to quality improvement. Our aluminium sand castings not only enhance the efficiency of automotive production but also contribute to sustainability through their recyclability. Join us in exploring how aluminium sand casting can elevate your product offerings and meet the needs of a competitive global market.

Step-by-Step Guide Aluminium Sand Casting Is The Best Products

| Process Step | Description | Benefits | Applications |

|---|---|---|---|

| Pattern Making | Creating a mold pattern from the desired shape. | High accuracy and repeatability. | Automotive parts, machinery. |

| Mold Preparation | Preparing the mold with sand and binders. | Cost-effective for complex shapes. | Industrial components, decorative items. |

| Melting & Pouring | Melting aluminum and pouring it into the mold. | Efficient use of materials reduces waste. | Aerospace parts, sports equipment. |

| Cooling & Shakeout | Allowing the cast to cool and separating mold from casting. | Minimizes defects in final products. | HVAC components, appliance parts. |

| Finishing | Trimming excessive material and surface finishing. | Improves appearance and surface quality. | Consumer products, electronic housings. |

How To Evaluate Aluminium Sand Casting Is The Best Outperforms the Competition

I

Isabella Garcia

The durability of this product is impressive. The after-sales support exceeded my expectations with their quick response and expertise.

16 May 2025

G

Grace Wright

This product stands out in quality! The professional support staff made my purchasing journey seamless and enjoyable.

21 May 2025

O

Oliver Brown

Superb product quality! The after-sales staff were impressive, providing expert assistance whenever needed.

28 June 2025

P

Peyton Williams

Fantastic product quality! I was very impressed with the knowledgeable support staff throughout the process.

12 June 2025

E

Elena Carter

Impressive product quality! The professionalism exhibited by the support staff made my experience extremely positive.

03 June 2025

A

Addison Hughes

Fantastic experience with this product! The support staff was friendly, experienced, and truly helpful through the entire process.

11 June 2025