+86-13516964051

+86-13516964051 High-Quality Aluminium Alloy Die Casting OEM Services from Reliable Manufacturers

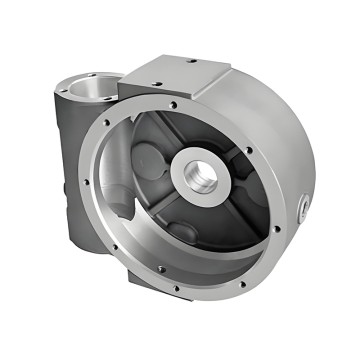

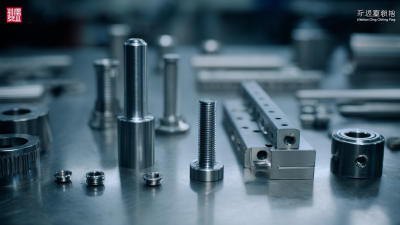

At Yongkang Hantai Industry And Trade Co., Ltd., we prioritize quality in Aluminium Alloy Die Casting. We recognize the importance of partnering with trustworthy suppliers to achieve outstanding results. Our extensive industry experience allows us to deliver high-quality die casting services tailored to various requirements. By fusing advanced technology with expert craftsmanship, we produce durable and precise components. Our commitment is to ensure that every client receives exceptional products that enhance their operations. From design to delivery, our dedicated team is here to assist you, making the process seamless and helping you meet your business goals. Together, we can elevate your projects with our expertise in Aluminium Alloy Die Casting. Contact us to find out how we can assist you!

10 Essential Tips For Aluminium Alloy Die Casting Where Innovation Meets 2025 Industry Giant

In the rapidly evolving landscape of the automotive industry, aluminium alloy die casting has emerged as a cornerstone for innovation and efficiency. As we look towards 2025, it’s crucial for global buyers to grasp the essential techniques to leverage this advanced manufacturing process. At Yongkang Hantai Industry & Trade Co., Ltd., established in 1997, we prioritize technological innovation and quality improvement, dedicating ourselves to providing high-quality parts and components tailored to the automotive sector. To maximize the benefits of aluminium alloy die casting, sourcing professionals should focus on selecting suppliers that emphasize continuous innovation and stringent quality controls. It is vital to assess a manufacturer's capacity for adapting to new technologies and their commitment to sustainable practices, which not only ensures compliance with environmental regulations but also enhances the overall value of the products. Moreover, collaboration with suppliers who understand the nuances of material properties and Casting Techniques will lead to improved product performance and reduced production costs. As we approach 2025, embracing the latest trends in aluminium alloy die casting can significantly impact procurement strategies. Emphasizing relationships with dynamic suppliers like Yongkang Hantai, who prioritize innovation and efficiency, will position global buyers to meet the demands of an increasingly competitive automotive market. By focusing on these essential tips, procurement professionals can ensure they are not only meeting current industry standards but are also paving the way for future advancements in automotive manufacturing.

10 Essential Tips For Aluminium Alloy Die Casting Where Innovation Meets 2025 Industry Giant

| Tip Number | Tip Description | Expected Benefits | Implementation Difficulty |

|---|---|---|---|

| 1 | Optimize die design for thermal efficiency. | Reduced cycle times and improved quality. | Medium |

| 2 | Implement advanced simulation software. | Increased accuracy in defect prediction. | High |

| 3 | Utilize high-quality raw materials. | Enhanced product durability and performance. | Low |

| 4 | Incorporate automation in the Casting Process. | Increased throughput and decreased labor costs. | High |

| 5 | Enhance surface finish techniques. | Improved aesthetics and corrosion resistance. | Medium |

| 6 | Conduct thorough training for workers. | Increased efficiency and reduced errors. | Medium |

| 7 | Adopt sustainability practices. | Reduced environmental impact and compliance costs. | Medium |

| 8 | Regular maintenance of equipment. | Decreased downtime and extended equipment life. | Low |

| 9 | Invest in research and development. | Innovative solutions and staying competitive. | High |

| 10 | Leverage data analytics for production optimization. | Enhanced decision-making and efficiency. | High |

Step-by-Step Guide Aluminium Alloy Die Casting Now Trending in 2025

J

Jackson Allen

The item exceeded all my expectations in quality. The support team was professional, friendly, and incredibly helpful throughout the process.

21 June 2025

G

Grace Wright

This product stands out in quality! The professional support staff made my purchasing journey seamless and enjoyable.

21 May 2025

H

Hannah Turner

Absolutely love this product! The support team demonstrated high expertise and effectively addressed all my questions.

05 June 2025

H

Hazel Mitchell

Love the durability and quality of this item! Customer service was very professional and knowledgeable, which I appreciated.

24 May 2025

E

Elena Carter

Impressive product quality! The professionalism exhibited by the support staff made my experience extremely positive.

03 June 2025

R

Ronan Collins

This product is exactly what I was looking for! The support staff were informative and genuinely helpful.

05 July 2025